Customized Auto Glue Dispensing Screw Tightening Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Shanghai, Qingdao, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Suzhou, China |

|---|---|

| Productivity: | 2000SETS |

| Supply Ability: | 1000 Sets |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CIP,DDP,DDU,Express Delivery |

| Certificate: | ISO9001, ISO14001, CE |

| HS Code: | 84798999 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Shanghai,Qingdao,Shenzhen |

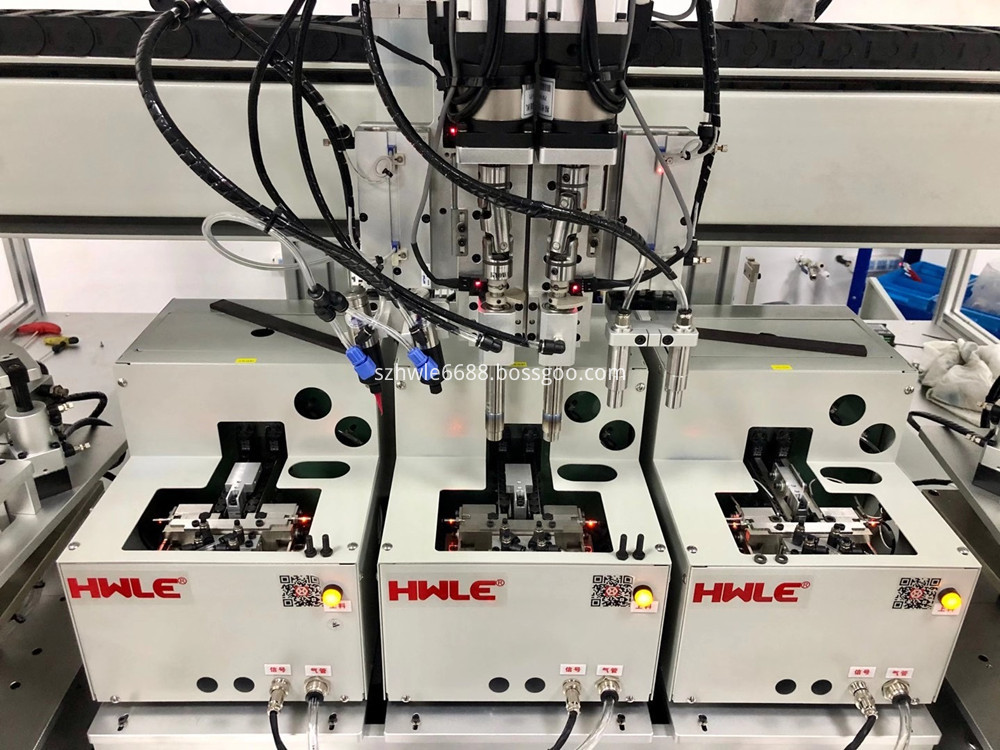

The Introduction of Multi-functional Auto Glue Dispensing Screw Tightening Machine

Fully Automatic Locking Screw Machine, also known as Automatic Screw Locking Machine, Automatic Screw Tighten And Glue Dispensing Machine,

According to the numbers of axis, it is divided into 3axis Robot Screw Machine, 4-axis Automatic Screw Locking Machine, 6 Axis Screw Locking Machine, and Multi-functional Auto Glue Dispensing Screw Tightening Machine, Robot Automatic Screw Driving Machine, Robotic Automatic Screw Fastening Machine etc.

It is composed of an automatic feeding screw head, a feeding system, a rotating disk, a fixture, a frame, a protection device, and a control part installed at a right angle.

Dispensing or screwing screws, dispensing at different angles, can accurately control the amount of glue.

Features of Multi-functional Auto Glue Dispensing Screw Tightening Machine

Dispensing glue or/and screwing screw, dispensing operation at different angles, can accurately control the amount of glue, so it is called automatic glue dispenser robot, or robot Automatic Screw Locking Machine.It is composed of an automatic feeding screw head, a feeding system, a rotating disk, a fixture, a frame, a protection device, and a control part installed at a right angle.

Applicable glue

Function

Dispensing, screwing

Catagory

Anaerobic glue, silica gel, heat-dissipating glue, AB glue

Specificaton

Working power supply

AC220V 50Hz 2000W

Working pressure

5.5±0.5kgf/cm2

Torque upper limit

300kgf.cm(30N.m)

Running accuracy

1000mm/sec ±0.02mm/axis

Control method

PLC+HMI industrial computer+display

Motion module

Servo motor + screw slide; linear motor + linear slide

Programming

Independent development of Chinese and English operating software

Feeding method

Pneumatic blowing, Pneumatic suction, Blowing and sucking (stapling rate≤1‰)

Working frequency

2.0-4.0s/time

Assembly process

Dispensing, gluing, screwing

Effective stroke

According to product customization

Integrated function

Dispensing assembly, setting glue amount + number of detection points + MES function Sliding teeth + floating lock + leaking lock alarm and prompt

Related Keywords