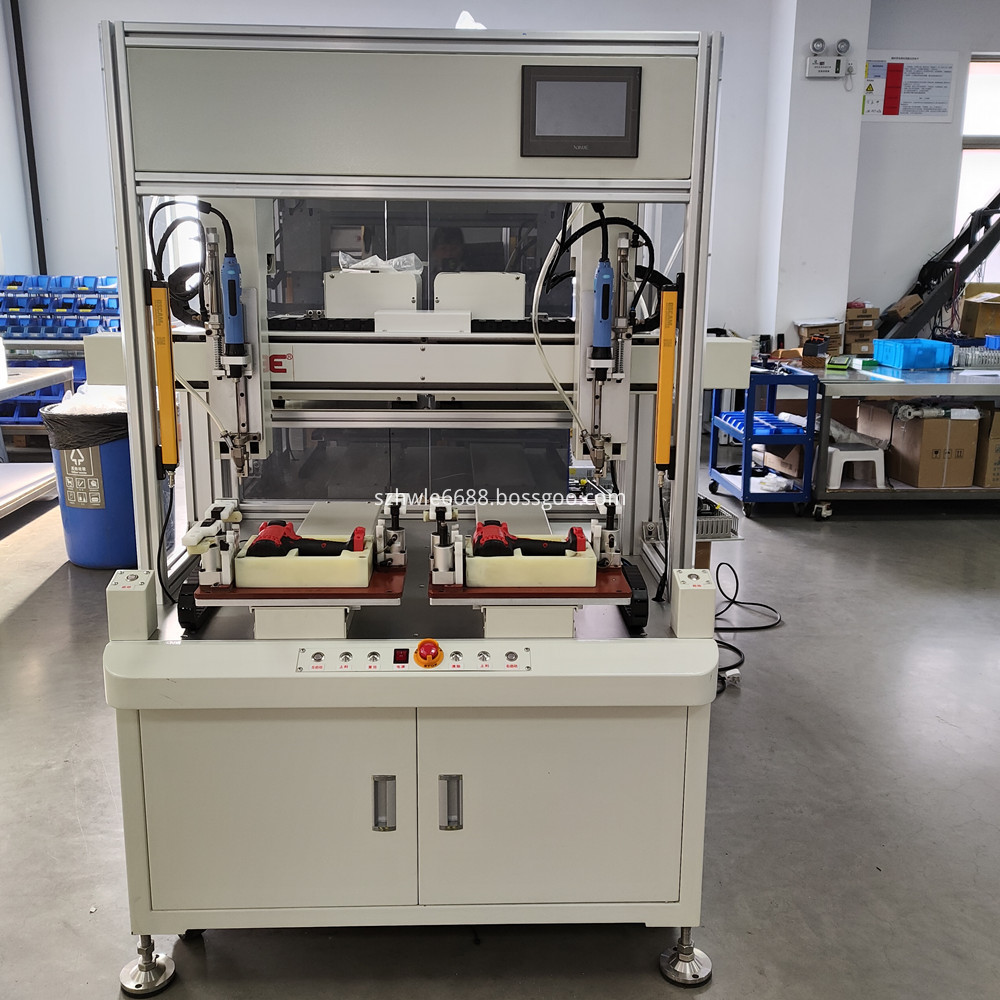

Electric Tools Six-axis Auto Screw Tighter Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Shanghai, Qingdao, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Suzhou, China |

|---|---|

| Productivity: | 1000SETS |

| Supply Ability: | 1000 Sets |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CIP,DDP,DDU,Express Delivery |

| Certificate: | ISO9001, ISO14001, CE |

| HS Code: | 84798999 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Shanghai,Qingdao,Shenzhen |

Automatic Locking Screw Machine also know as Screw Locking Robot, Robot Automatic Locking Screw Machine, Automatic Locking Screw Robot. It can be divided into Servo Automatic Screw Tighten Machine, Six Axis Automatic Screw Locking Machine, 4-axis Dual Station Robot Screw Tightening Machine etc.

Equipment description and main functions of the screw machine

Device Description:

1. It is mainly composed of screw automatic conveying system, screw locking mechanism, electrical control system, etc.;

2. Strong applicability, changing the product, only need to change the jig, and the position of the electric batch can be adjusted;

3. The screw is automatically fed. After the screw is locked on the batch head, the screw is automatically blown to the batch mouth by the air pipe;

4. Sliding tooth does not feed material: In the locking process, the torque cannot be reached, and the screw is not sent out, so as to prevent the phenomenon of material jamming in the batch nozzle;

5. Good stability, no material jam, even if the material is jammed due to a defect, the jam can be solved within a few seconds;

6. High efficiency, the time to lock and pay for a product is about 3S. (The length of the screw is slightly different), no need to grab the screw,

Just put the product on the fixture to operate the equipment;

7. It can reduce the screw lock operation of 2 to 5 workers, realize fully automatic production, reduce the labor intensity of workers and improve productivity;

8. The key parts are made of hardware materials and have been specially treated, and the original electronic components are used to ensure zero failure of the equipment

The main function:

1. With intelligent detection function, it can detect missing locks, floating locks, sliding teeth, etc.;

2. The locking plane is a horizontal plane, multiple electric batches can be locked at the same time, and 2-12 batches are optional;

3. The locking screw is: the provided model automatic screw, which allows the size tolerance of the incoming material to be within ±0.2

4. Lock payment products are: customized equipment according to the product samples provided by customers;

5. Fixtures: According to product design, place in multiple rows and columns. Require positioning accuracy and simple and convenient replacement;

6. No damage to the product during the use of the equipment (such as product deformation, scratches, appearance damage, etc.);

7. It can cooperate with the assembly line to realize automatic operation.

Related Keywords