Polyurethane liquid waterproofing membrane rubber for sole

- Min. Order:

- 1000 Kilogram

- Min. Order:

- 1000 Kilogram

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 150000tons/year |

| Supply Ability: | 150000tons/year |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,CIP |

| Certificate: | ISO9001/ISO14001 |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

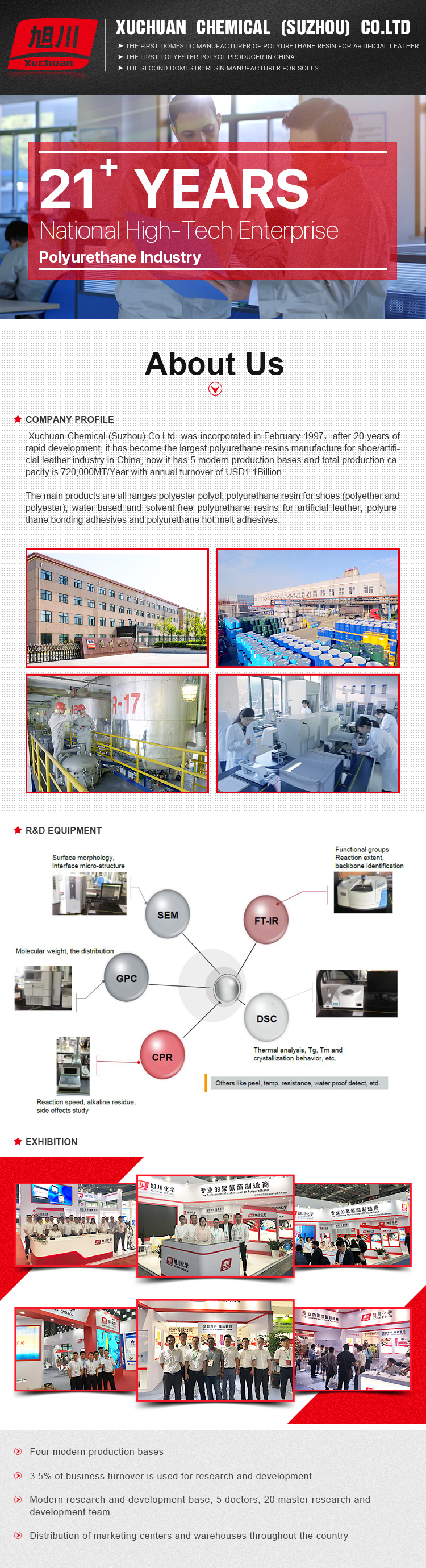

Polyurethane liquid waterproofing membrane rubber for mid-sole shoe

Product Detail

| Application | shoes insole |

| A/B Materials Temperatures (℃) | 40~45/38~42 |

| A+C/B Mix ratio (By weight) | 100/74~76 |

| Cream Time (s) | 7~9 |

| End of Rise Time (s) | 50~60 |

| Free Rise Foam Density(g/cm3) | 0.13~0.16 |

| Mold Temperature (℃) | 45~55 |

| Molded Density (g/cm3) | 0.30~0.40 |

| Hardness (Shore C ) | 35~45 |

| Tensile strength(MPa) | Tensile strength(MPa) |

|

Characteristic: Good handle, low density and good dimension stability, high elasticity |

|||||||

|

Application: Insole and low density mid-sole |

|||||||

|

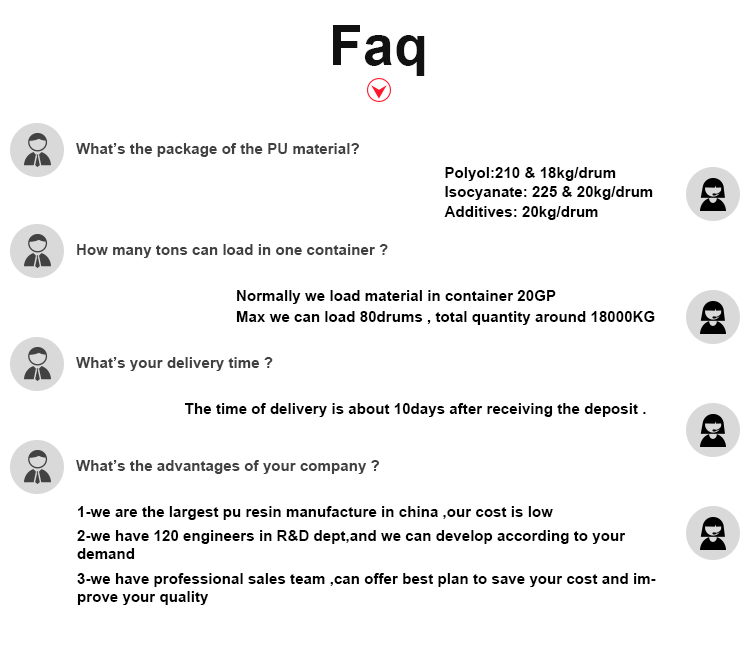

Typical properties of PU matrix |

|||||||

|

Name of products |

Appearance |

Viscosity (mPa·s/40℃) |

Density (g·cm-3/40℃) |

Package(kg) |

/ |

||

|

A-2001 |

Liquid |

1000~1400 |

1.01~1.02 |

18 |

|||

|

B-8580 |

Yellowish transparent liquid or waxy |

600~1000 |

1.08~1.2 |

20 |

|||

|

Materials preheat |

|||||||

|

A-2001: preheated at 50~60℃ for 8~10 hours. |

|||||||

|

B-8580: preheated at 50~60℃ for 8~12 hours. |

|||||||

|

Typical processing parameters & Reaction parameter |

|||||||

|

Items |

A/B Materials Temperatures |

A+C/B Mix ratio |

Cream Time (s) |

End of Rise Time (s) |

Free Rise Foam Density(g/cm3) |

Mold Temperature |

Demold Time(min) |

|

Parameter |

40~45/38~42 |

100/74~76 |

7~9 |

50~60 |

0.13~0.16 |

45~55 |

4~5 |

|

The adding content of C-2 should be 300g±20g/18kg. |

|||||||

|

The adding content of water should be 0~90g/18kg according to the reality. |

|||||||

|

Physical properties |

|||||||

|

Items |

Molded Density (g/cm3) |

Hardness |

Tensile strength(MPa) |

Elongation (%) |

Tear Strength |

/ |

|

|

Physical properties |

0.30~0.40 |

35~45 |

4.0~6.0 |

300~380 |

18~26 |

||

|

Demold time may be prolonged with the increase of sole thickness |

|||||||

|

These physical data are acquired by testing a sample of 6mm thick. |

|||||||

|

Data listed above are just for reference. The detail data are subjected to practical production. If other requests for physical properties, please contact us. |

|||||||

Related Keywords