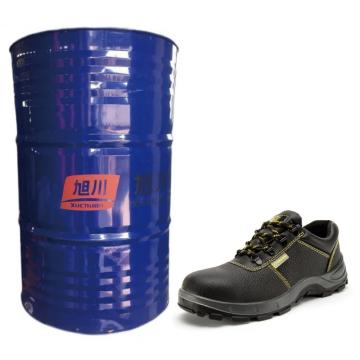

PU Resin For Safety Shoe Sole Polyester Resin

- Min. Order:

- 1000 Ton

- Min. Order:

- 1000 Ton

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 250000 tons/year |

| Supply Ability: | 150000 |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| HS Code: | 39095000 |

| Transportation: | Ocean |

| Port: | Shanghai |

PU Resin For Safety Shoes Materials

A-6170/B-8280

Shoe Sole Polyurethane Resins

|

Characteristic: high strength and cohesive force, good abrasion resistance |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Application: Double density sole system for common safety shoes and one-step forming casual shoes |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Typical properties of PU matrix

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials preheat A-6170: 50~60°C preheated at 50~60°C for 8~10 hours B-8280: 50~60°C preheated at 50~60°C for 8~12 hours |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Typical processing parameters & Reaction parameter

The adding content of water and hardener should be changed according to the reality Hardener 0~400g/18kg Mid-sole: H2O 50~55g/18kg Hardener 0~600g/18kg |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Polyester Polyol Isocyanate Physical properties

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Demold time may be prolonged with the increase of sole thickness These physical data are acquired by testing a sample of 6mm thick.

|

||||||||||||||||||||||||||||||||||||||||||||||||

Related Keywords