PU Resin for Synthetic Bags Leather/Sofa Leather

-

$2.38≥1000 Kilogram

- Min. Order:

- 1000 Kilogram

- Min. Order:

- 1000 Kilogram

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 450000tons/year |

| Supply Ability: | 450000tons/year |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CIF,CIP,EXW |

| Certificate: | ISO9001/ISO14001 |

| HS Code: | 39095000 |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

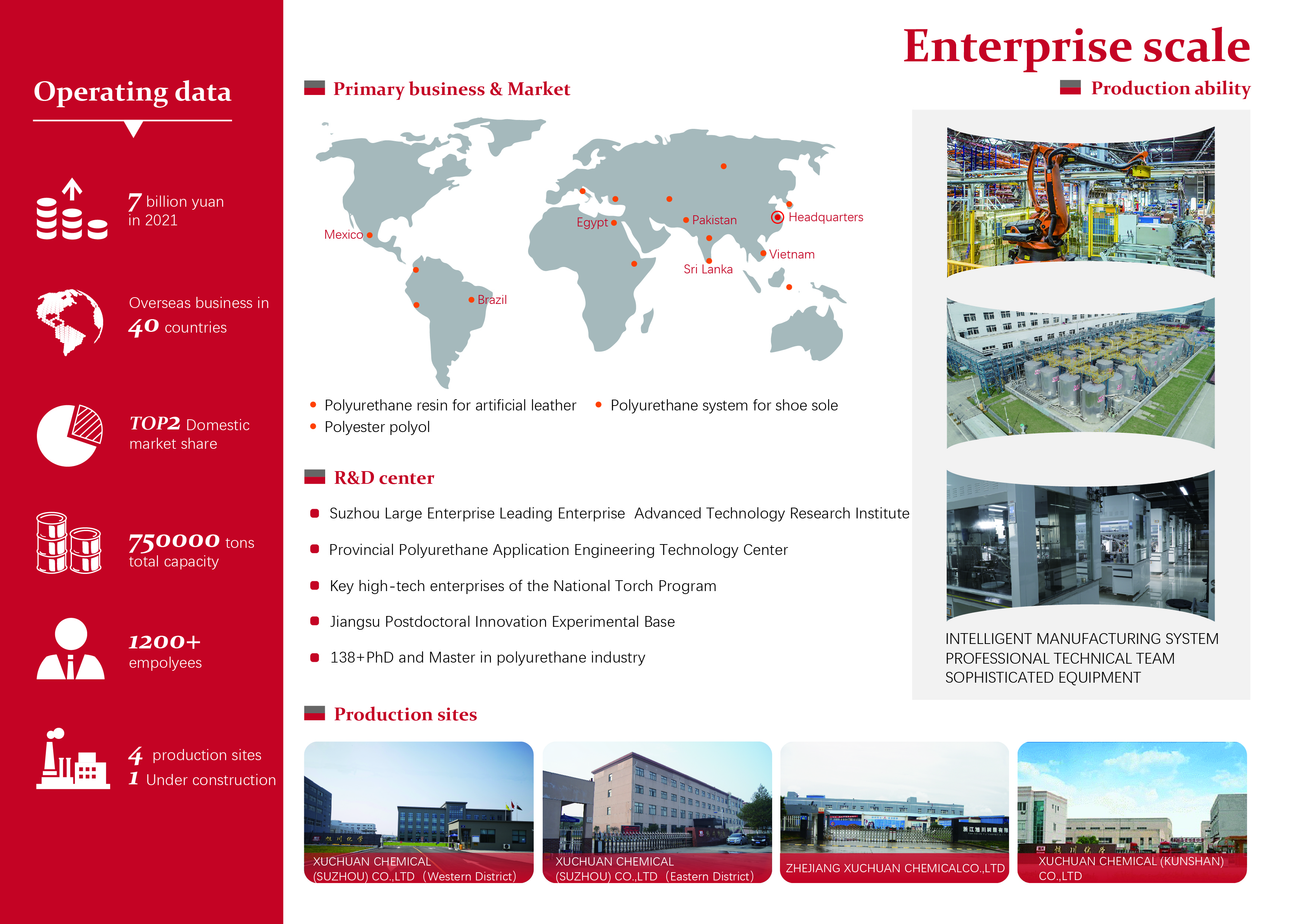

Xuchuan Chemical established in 2007, company registered capital is RMB 500 million. The main products are all ranges polyester polyol, polyurethane resin for shoes, water-based and solvent-free polyurethane resins for artificial leather, polyurethane bonding adhesives and polyurethane hot melt adhesives.

manufacturer for PU System for Shoe Sole, Adhesive for Shoes, TPU, CPU, Polyester Polyol, PU Resin for Ink, PUR Hot Melt Adhesive, Adhesive for Flexible Package, PU Resin for Synthetic Leather.

Now Xuchuan has 4 modern production bases, production capacity reached 920,000 tons per year, products exported to 40 countries and regions in the world.

polyester polyols and PU resin, specializing in producing polyester polyols, PU resin for shoe sole, PU ,resin for synthetic leather, PU resin for textile finishing, PU resin for ink binder, PU adhesive, PUprepolmer, PU melting adhesive, waterborne PU resin and non-solvent PU resin etc.

| Coagulation process | ||||||

| Code | Solid Content(%) | Viscosity(cpa.s/25℃) | Modulus(kg/c㎡) | Tensile Strength(kg/c㎡) | Elongation(%) | Characteristics and Application |

| XCW-6030KB | 30±1 | 160000-220000 | 35 | 350 | 600 | Soft type, good film thickness, suit for garment, shoes, bags |

| XCW-6100T | 30±1 | 160000-220000 | 100 | 550 | 400 | Mid-hard, good wet film-forming, suit for shoes |

| XCW-6244 | 30±1 | 160000-220000 | 240 | 600 | 300 | Hard, good wet film-forming, suit for shoes |

| XCW-6400M | 30±1 | 160000-220000 | 440 | 650 | 200 | Extra-hard, good wet film-forming, suit for shoes |

| XCW-80MK(S) | 30±1 | 150000-220000 | 80 | 400 | 350 | Mid-hard grade, good embossing effect and color changing effect, suit for trademark leather |

| XCW-6010HH | 30±1 | 160000-220000 | 10 | 350 | 650 | Good wet film-forming, smooth in surface, low trackiness in surface, extra soft grade, good embossing effect, suit for garment, shoes,bags |

| XCW-8955 | 30±1 | 180000-220000 | 50 | 500 | 450 | Mid-hard, 5 years hydrolysis resistance, suit for sofa, shoes |

| XCW-8980 | 30±1 | 180000-220000 | 80 | 550 | 400 | Mid-hard, 5 years hydrolysis resistance, suit for sofa, shoes |

| XCW-SP90 | 30±1 | 80000-120000 | 90 | 550 | 450 | Wet mid-hard grade, suit for shoes leather |

| Dry process | ||||||

| Code | Solid Content(%) | Viscosity(cpa.s/25℃) | Modulus(kg/c㎡) | Tensile Strength(kg/c㎡) | Elongation(%) | Characteristics and Application |

| XCS-2033B | 30±1 | 120000-160000 | 30 | 450 | 600 | Low tackiness, suit for split leather, garment, shoes, sofa |

| XCS-2083B | 30±1 | 120000-160000 | 60 | 550 | 450 | Mid-soft grade, good slip effect, suit for shoes, bags, sofa |

| XCS-3054B | 30±1 | 120000-160000 | 50 | 350 | 500 | Mid-soft grade, good hydrolysis resistance and cold resistance |

| XCS-3060SW | 30±1 | 100000-140000 | 55 | 350 | 450 | Mid-soft grade, flexibility at low temperature, high bonding strength, good hydrolysis resistance, suit for shoes |

| XCA-4548K | 30±1 | 90000-120000 | 35 | 400 | 600 | One component type pu adhesive, which has good hydrolysis-resistance and cold-resistance |

| XCY-5575 | 30±1 | 20000-40000 | 100 | 400 | 400 | Aliphatic type, low viscosity, fast drying speed, good penetration, plasticizer resistance, suit for shoes, surface treatment, semi-PU, etc. |

| XCY-55230 | 30±1 | 150000-40000 | 220 | 400 | 400 | Aliphatic type, low viscosity, fast drying speed, good penetration, plasticizer resistance, suit for shoes, surface treatment, |

| semi-PU, etc. | ||||||

| XCS-80PA | 30±1 | 100000-140000 | 80 | 500 | 400 | Mid-hard grade PVC surface layer resins, suit for bags, sofa |

| Frabric use | ||||||

| Code | Solid Content(%) | Viscosity(cpa.s/25℃) | Modulus(kg/c㎡) | Tensile Strength(kg/c㎡) | Elongation(%) | Characteristics and Application |

| XCS-30DC | 30±2 | 90000-120000 | 30 | 350 | 650 | Soft grade, topcoat, excellent water pressure resistance, suit for for garment, tent |

| XCS-90DC | 30±3 | 90000-120000 | 90 | 550 | 450 | Mid-hard grade, topcoat, excellent water pressure resistance, suit for garment, tent |

| XCM-310S | 30±1 | 60000-90000 | 15 | 400 | 700 | Top coat, soft grade, moisture permeability, good touch, direct coating, suit for garment |

| XCM-510D | 55±1 | 60000-90000 | - | - | - | Two component primer, soft grade, moisture permeability, good touch, high bonding strength, direct coating, suit for garment |

| Adhesive resins | ||||||

| Code | Solid Content(%) | Viscosity(cpa.s/25℃) | Modulus(kg/c㎡) | Tensile Strength(kg/c㎡) | Elongation(%) | Characteristics and Application |

| PU-9600 | 67±1 | 110000-130000 | - | - | - | Soft grade, topcoat, excellent water pressure resistance, suit for for garment, tent |

| XCA-55 | 50±1 | 100000-140000 | 50 | 300 | 500 | High bonding strength, plasticizer resistance, suit for bags, sofa leather |

| PU FINISHING CHEMMICALS | ||||||

| CATEGORY | Code | Solid Content(%) | Viscosity(cpa.s/25℃) | Solvent | Characteristics and Application | |

| High Solid Super Gloss Finishing | SC-1400H | 30±2 | 1000-4000 | DMF/MEK | Soft grade, topcoat, excellent water pressure resistance, suit for for garment, tent | |

| Matt Slippery Finishing | SC-2122 | 20±1 | 300-700 | DMF/TOL/MEK | Very nice matt surface with slippery hand touch feeling, excellent color rendering | |

| Matt Weak Solvent Super Black Finishing | SC-2865D | 15±1 | 100-800 | IPA/TOL | Very nice aliphatic matt surface, deep blackness, excellent color rendering. Suitable for 100% PVC leather | |

| Matt Smooth Waxy Finishing | SC-3266F | 18±1 | 1000-1300 | DMF/MEK | Yellowing waxy matt surface with smooth soft skin touch, excellent color rendering. | |

| Carbon Black Finishing | SC-8950 | 35±1 | 200-1000 | IPA/DAA/TOL | Non-yellowing Carbon black finish lacqure, very deep blackness, excellent color rendering | |

| Oil Gloss Brushoff Finishing | SC-7003 | 27±1 | 200-1000 | DMF/TOL/MEK | Oily burnish finish with high glossness, strong brushoff effect, excellent color gradation. | |

| Fine YangBuck Skin Touch Resin | SC-97410 | 25±1 | 3000-7000 | DMF/TOL/MEK | Fine fluffy genuine leather imitation, very nice skin touch feeling, excellent color rendering effect. Suitable for 100% PVC leather, PVC/PU Semi PU leather, 100% PU leather | |

| Rough YangBuck Skin Touch Resin | SC-97450 | 25±1 | 3000-7000 | DMF/TOL | Medium fluffy genuine leather imitation, excellent color rendering effect. Suitable for PVC/PU Semi PU leather, 100% PU leather | |

| Fluffy YangBuck Skin Touch Resin | SC-97480 | 22±1 | 3000-7000 | DMF/TOL | Fine fluffy genuine leather imitation, strong rough hand touch feeling, excellent color rendering effect. Suitable for PVC/PU Semi PU leather, 100% PU leather | |

Related Keywords