Moisture-reactive polyurethane for textile bonding

- Min. Order:

- 3 Ton

- Min. Order:

- 3 Ton

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 260000tons/year |

| Supply Ability: | 250000 tons/year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Moisture Curing Pu Adhesive

XCUR-M5045

|

|

Specification

|

|

Solid content (%)

|

100

|

|

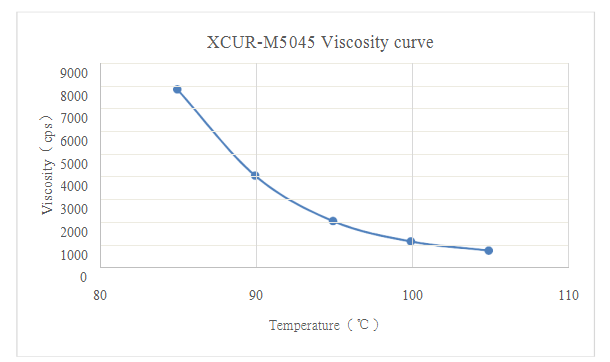

Viscosity(Ps/90℃)

|

4500±1500

|

|

Appearance

|

Transparent paste

|

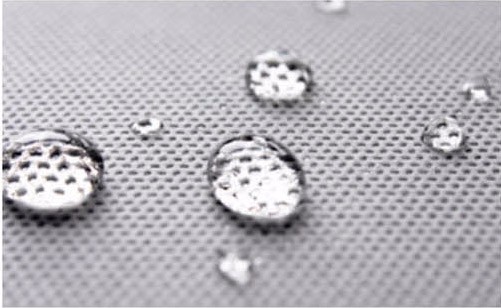

1. Characteristic: Long operation time for resin, low operation temperature, strong initial adhesive force, fast curing speed, high peeling strength.

2. Application: It can be widely used in garment fabrics, medical supplies - surgical gowns, industrial fabrics and so on.

V. Processing advice

1. Processing temperature: 80~100℃;

2. Processing humidity: 50~70%, if you need to speed up the curing speed, you can increase the ambient humidity properly;

3. Curing environment temperature: 25~35℃;

4. Since PUR hot melt adhesive is a moisture curing type polyurethane resin, so it must be stored in a sealed bag, if exposed to moisture, the surface cures to form rubber and the viscosity increases dramatically;

5. After opening the bag, it is recommended to use it as soon as possible, but it should not be exposed to the air for a long time;

6. Shelf life:6 months.

VI. Cleaning

1.Use waste cloth to wipe nozzle or barrel to remove excess PUR hot melt adhesive;

Add special PUR detergent to mix with unreacted PUR hot melt adhesive for 5~10 minutes.

Related Keywords