Hot melt Adhesive for textile

- Min. Order:

- 3 Ton

- Min. Order:

- 3 Ton

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 260000tons/month |

| Supply Ability: | 250000 tons/year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

XCUR-M5350

Moisture-curable polyurethane hot melt adhesive for textile Moisture Curing Pu Adhesive

Reactive Polyurethane Glue Description:

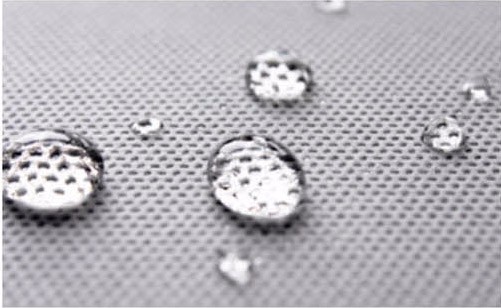

XCUR-M5350 is a one component moisture-curable polyurethane hot melt adhesive used for textile fabric composite and fitting composite of water-proof fabric and TPU films, recomended to be used for the lamination for medical protecttive clothing

Specification:

|

Properties

|

Code

|

|

Solid content (%)

|

100

|

|

Viscosity(Cps/90℃)

|

25000~35000

|

|

Appearance

|

Paste

|

|

100% M(Kgf/cm2)

|

12~16

|

|

T.S(Kgf/cm2)

|

100~120

|

|

EL(%)

|

400~600

|

Pu Glue For Textile Properties and Applications:

Characteristics: long pot-life, low operated temperature and fast curing speed with good initial adhesion. it can achieve soft feeling with high strength and tenacity fitting effect after cured.

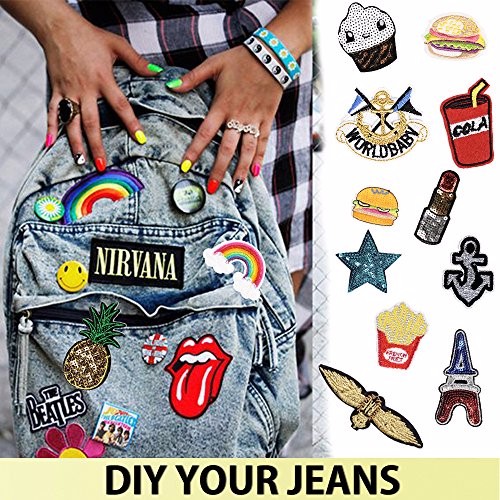

Usage: widely used in garment fabric, medical supplies, industry fabric.

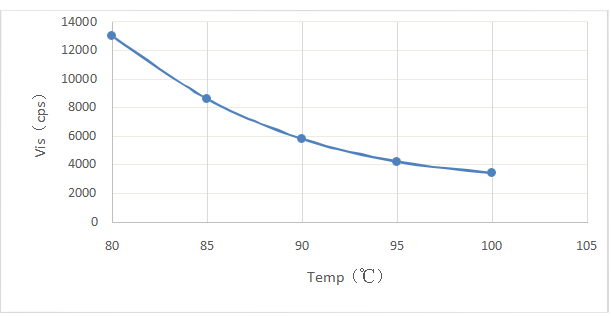

Viscosity curve

Processing suggestion

1.Process temperature: 80~100℃.

2.Process humidity: >50%, the curing speed can be improved if the ambient humidity increased.

3.storage: stored in sealed Package. in case of moisture, there would be a solidified film on the surface and the viscosity would dramatically increase.

4.When you used PU Reactive HMA , don’t subpack it again and use it to finish.

5.Shelf-life: 6 months.

Cleaning

1.Waste cloth is suggested to wipe out the residual PUR hot melt adhesive on nozzle or barrel.

2.Mix the unreacted PUR hot met adhesive with special cleaning agent for 5 to 10 min.

Other Reminds

1.Personal protective equipment(PPE) is essential in case of scald.

2.Please use it in a well ventilate condition in case of allergic effects for the long-term contact with a small amount of isocyanates in the product.

Detailed Images

Related Keywords