XCPU-E150 POLYESTER PREPOLYMER For Sealing Ring

- Min. Order:

- 1000 Kilogram

- Min. Order:

- 1000 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

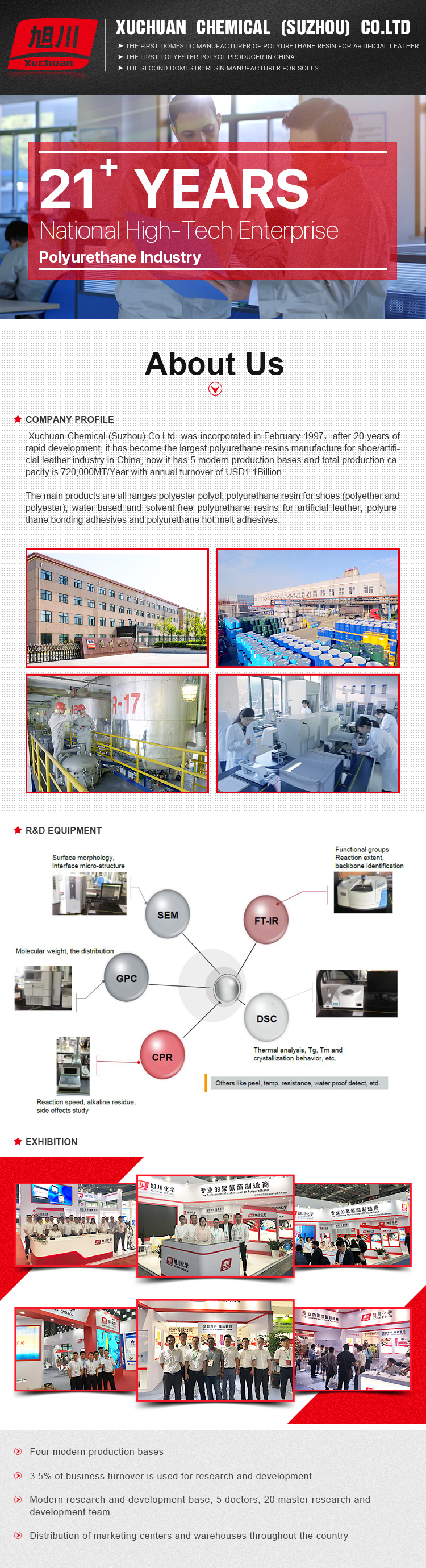

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 260000tons/year |

| Supply Ability: | 250000 tons/year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Polyether Polyurethane Prepolymer

Product Description

Cpu For Elastomers

|

POLYSETER PREPOLYMER XCPU-E150 |

1,This product is a polyester polyol and toluene diisocyanate (T-100) in the synthesis

of polyester polyurethane prepolymer

2,Features: excellent wear resistance, oil resistance, mechanical properties

3,Uses: Sieve, machinery parts, sealing ring, PU roller and other products

4,Product Specifcation

|

Name of products |

Appearances |

Viscosity(mPa.s/85℃) |

NCO% content |

Package(kg) |

|

XCPU-E150 |

solid |

1100-1200 |

5.00-5.20 |

20 / 200 |

5,Mixing and Curing Conditions

|

MOCA Level |

Recommended % Theory |

Prepolymer Temperature |

Curative Temperature |

Pot Life |

Demould Time |

Post Cure Time |

|

% |

% |

℃ |

℃ |

mins |

@ 100°C (hrs) |

@ 100°C (hrs) |

|

15 |

95 |

75-85 |

110-120 |

5-6 |

1 |

10 |

6,Processing Procedure:

Prepolymer at 75 ~ 85 ℃ preheating, after vacuum degassing, the melt MOCA good homogeneous mixing, deaeration, pouring, molding, vulcanization molding, stripping, vulcanization.

7,Physical Properties

Properties presented below are to be used as a guide and not intended for specification purposes.

|

Hardness |

Shore A |

95 |

|

Tensile Strength |

MPa |

53 |

|

100% Modulus |

MPa |

8.6 |

|

300% Modulus |

MPa |

15.4 |

|

Angle Tear Strength, Die C |

kN/m |

111 |

|

Trouser Tear Strength |

kN/m |

45 |

|

Elongation |

% |

600 |

|

Resilience |

% |

37 |

|

DIN Abrasion Resistance 10N |

mm 3 |

51 |

|

Cured Specific Gravity |

g/cm3 |

1.27 |

Prepolymer For Pu Plate

Related Keywords