Wood Plastic Composite pillar Production Line

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 50 Days

- Transportation:

- Ocean

- Port:

- Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | china |

|---|---|

| Productivity: | 80-120KG/H |

| Supply Ability: | 10set per month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE |

| HS Code: | 84778000 |

| Transportation: | Ocean |

| Port: | Shanghai |

Product Description

Product Description

Production Introduction

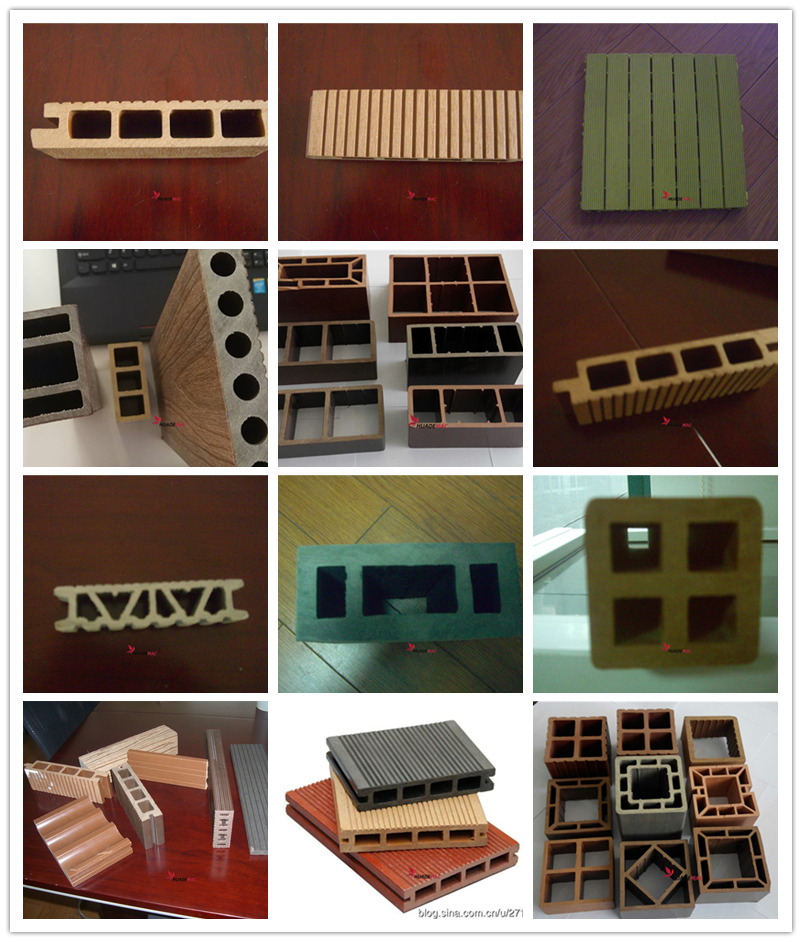

This WPC machine is used for making WPC profiles by Wood and Plastic composition, such as WPC decking, WPC wall cladding, WPC fencing, WPC pergola, WPC post, etc.PP/PE WPC profile production line can continuously produce PP/PE WPC profile.

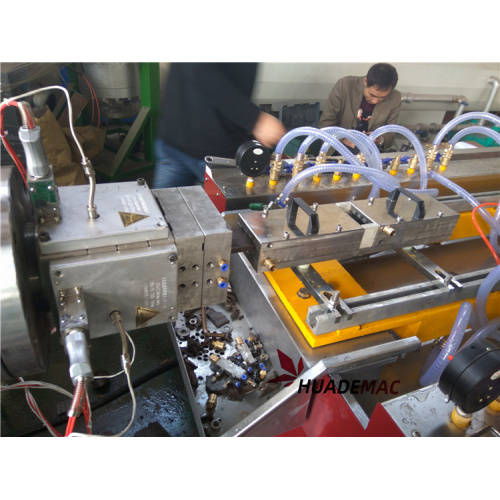

The WPC profile adopts two-step production process.The first step is using WPC granulating machine to make WPC pellets from recycled PP/PE material,wood powder and chemical additives.The max wood percentage can be 65%.The the WPC profile extrusion line will make the WPC pellets into WPC profiles by equip customized mold.We can equip on-line embossing machine to achieve 3D wooden pattern.

The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

It's a new environment protecting product, which combines the wood powder and plastic powder at a certain percent.

After the high temperature and mould extruding, the wood and plastic composites and becomes the final products.

WPC products: lowest pollution, anti-acid and alkali-proof, water proof, anti-rot, non-poison and non-smell,high-strength, recycling, etc.

Technical Specification:

|

Model

|

HD180

|

HD240

|

HD300

|

HD400

|

|

Max width of product (mm)

|

180

|

240

|

300

|

400

|

|

Extruder model

|

SJSZ55/110

|

SJSZ65/132

|

SJSZ65/132

|

SJSZ65/132

|

|

Max extrusion

Capacity (kg/hr)

|

150

|

250

|

250

|

250

|

|

Extruder power (KW)

|

22

|

30/37KW

|

30/37KW

|

30/37KW

|

|

Cooling water (m3/hr)

|

5

|

7

|

7

|

8

|

Company Information

Packaging & Shipping

Related Keywords

Related Keywords

You May Also Like

You May Also Like