Small scale plastic extruder

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 5 |

| Supply Ability: | 10 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE |

| HS Code: | 84772090 |

| Transportation: | Ocean |

| Port: | Shanghai |

Front and Rear Co-Extrusion Single Screw Extruder

Mini Extruder For Laboratory

Pipe Color Strip Extruder

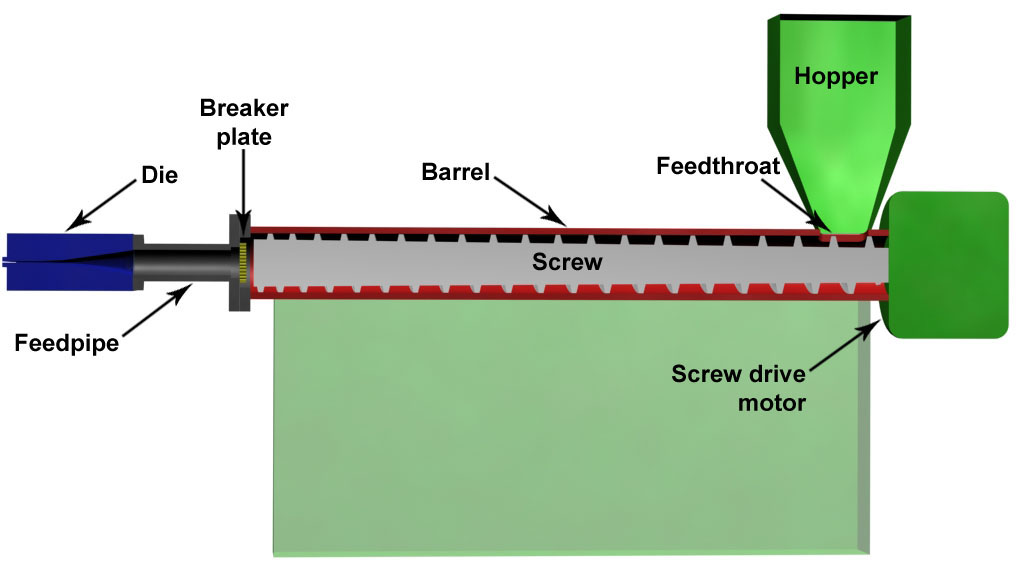

In the extrusion of plastics, the raw compound material is commonly in the form of nurdles (small beads, often called resin) that are gravity fed from a top mounted hopper into the barrel of the extruder. Additives such as colorants and UV inhibitors (in either liquid or pellet form) are often used and can be mixed into the resin prior to arriving at the hopper. The process has much in common with plastic injection molding from the point of the extruder technology, although it differs in that it is usually a continuous process. While pultrusion can offer many similar profiles in continuous lengths, usually with added reinforcing, this is achieved by pulling the finished product out of a die instead of extruding the polymer melt through a die.

Technical Specifications:

|

Model |

SJ25/25 |

SJ30/25 |

SJ45/25 |

|

Main motor power(kw) |

1.1 |

2.2 |

4.5 |

|

Screw diameter(mm) |

25 |

30 |

45 |

|

L/D ratio |

25 |

25 |

25 |

|

Capacity(kg/h) PE, PP |

45 |

10 |

20 |

|

Capacity(kg/h) PVC |

5 |

12 |

20 |

|

PMMA, ASA |

4 |

10 |

15 |

Related Keywords