PE PP waste rigid plastic recycling machine

- Payment Type:

- T/T, D/P

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,D/P |

|---|---|

| Incoterm: | FOB |

| Transportation: | Ocean |

| Port: | SHANGHAI |

PP PE bottle washing line

Made by Huade machinery, Which is used to recycle PP PE bottles.

By crushing or shredding,washing.and drying.

You will get clean and dry PP PE bottle flakes,the flake’s size can be 12-16mm.

With a pelletizing line, the waste plastic can be reused for producing baskets, pipes, bags,injection. etc.

The capacity of Foam ps eps eva epe wahsing line:

1. 300kg per hour 2. 500kg per hour 3. 1000kg per hour 4. 1500kg per hour 5. 2000kg per hour 6. 3000kg per hour

Related machine:

1.Dose feeding pelletizing line

2.Force feeding pelletizing line

The recycling process and machine details:

1.crusher

Function :

Crush waste plastic film to suitable size. Good for washing and drying.

2.Friction machine

Function :

Remove dirt or sand by friction paddles with or without water.

Model 1: screw type friction washer

Model 2: Wet Frction washer

3.Hot water washing tank

Function :

It use hot water to wash the oil and chemical polution

4.Floating washing tank

Function :

Wash away dirt with stirring paddles

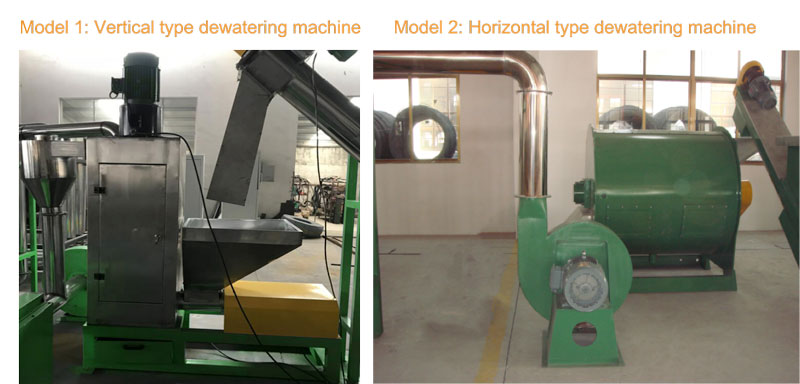

5.Dewatering machine

Function :

Dry the crushed cleaning rigid plastic scraps after washed

6.Hot air dryer pipe

Function :

Further Drying washed rigid plastic scraps

7.Zig-zag label remover

Function :

adopt specific gravity to separate the label and dust from plastic pp/pe scrap

8.product

Packaging&Exhibition:

Related Keywords