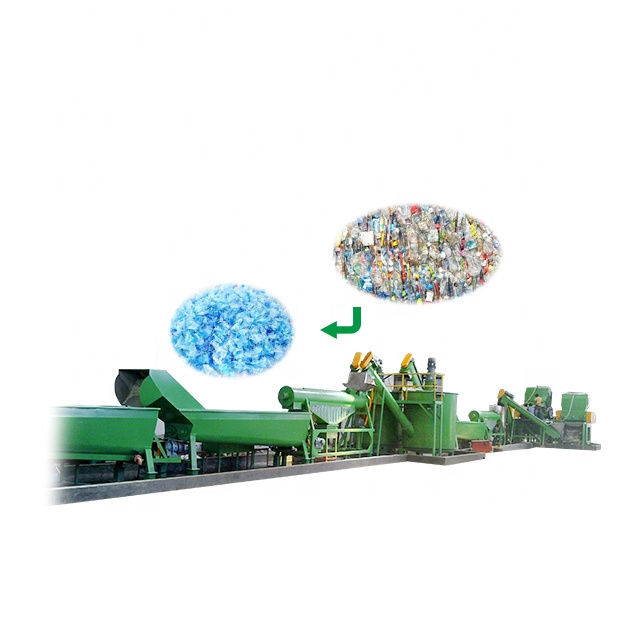

Waste PET bottles reprocessing line/machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 80 Days

- Transportation:

- Ocean

- Port:

- Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | CHINA |

|---|---|

| Productivity: | 2000kG |

| Supply Ability: | 10SETS |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE |

| HS Code: | 84778000 |

| Transportation: | Ocean |

| Port: | Shanghai |

Product Description

Product Description

Product Information

PET bottle washing line

Introduction:

The PET bottle recycling plant takes dirty bottles and transforms them into clean PET flakes. This is an export commodity which can be sold and used for many creative applications. And the flakes can be further processed and reutilized with high commercial value. The production capacity we can make on the PET Bottle washing and recycling line can be 100kg to 3000kg per hour.

Features:

1. Coordinating the production line with follow programmed work (granulating system), and it will make waste and dirty PET bottles to be the PET granule material and in order to producing new PET bottles.

2. Friendly control system (PLC integrated & separated control on each machine) and touch screen panel, easy for operation,monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 and touch screen panel, easy for operation,monitor and emergency stop.

4. The whole production line can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products.

System configuration:

|

NO.

|

Machine Name

|

Note

|

|

1

|

Bale breaker

|

Custom

|

|

2

|

Belt Conveyor

|

PVC Belt

|

|

3

|

Metal detector

|

Custom

|

|

4

|

Label Remover

|

Remove the label from the bottles.

|

|

5

|

Manual Sorting Belt

|

Custom,PVC Belt

|

|

6

|

Belt Conveyor

|

PVC Belt

|

|

7

|

Crusher

|

Blade metal:alloy(9CrSi or SKD-II)

|

|

8

|

Screw Loader

|

Made of Stainless steel

|

|

9

|

Hot Washer

|

Made of Stainless steel ,can put some soda

|

|

10

|

High-speed Friction Washer

|

Made of Stainless steel

Can be design Two-screw

|

|

11

|

Sink-Float Tank

|

Single-screw or Two-screw

|

|

12

|

Dewatering Machine

|

Vertical or Horizontal

|

|

13

|

Drying system

|

Made of Stainless steel

|

|

14

|

Storage hopper

|

Normally 1000L

|

|

15

|

Flakes Pneumatic Separating Machine

|

New style label remover for flakes

|

Details Images

Company Information

Suzhou Zhongsu Reprocessing Machinery Co.,Ltd.(Including subsidiaries:Zhangjiagang Zhongsu Co.,Ltd.&Greenwill Machinery Co.,Ltd.)is the key enterprise that specializes in manufacturing plastic recycling machines professionally in China.In recent years, we are engaged in developing and pruducing plastic recycling machines(including Shredder,Crushing,Washing,pelletizing and related Auxiliary Recycling machines).On the basis of our own technologies,we keep introducing advanced technologies from domestic and abroad markets.Meanwhile,we improve our recycling machines continuously by absorbing customers' working sites operation experience.Most of our recycling machinery products are exported to European and North American countries, Russia,Middle East,South America and Southeast Asia areas.

Packaging&Shipping

FAQ

Why choose us:

1.low cost :

all the machine ,we make it ourself to reduce the cost of our customer.

2.Genuine product with excellent quality :

we choose our material very strict,

all the material come to our factory must pass the quality test

substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4.quick delivery:

the company provide just in time delivery with its streamlined supply chain

5.cost saving:

we take strong attention to every detail in the manufacturing process,

the quality control in our factory is very strict,

all defective semi-manufactures must be treated again or reject.

all the machine must be checked out ,then deivered to our customer.

all about that pushing up the price,

what we want to do is give our customer a good quality product with stable working and long lived.

1.low cost :

all the machine ,we make it ourself to reduce the cost of our customer.

2.Genuine product with excellent quality :

we choose our material very strict,

all the material come to our factory must pass the quality test

substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4.quick delivery:

the company provide just in time delivery with its streamlined supply chain

5.cost saving:

we take strong attention to every detail in the manufacturing process,

the quality control in our factory is very strict,

all defective semi-manufactures must be treated again or reject.

all the machine must be checked out ,then deivered to our customer.

all about that pushing up the price,

what we want to do is give our customer a good quality product with stable working and long lived.

Contact us

If you need more machine details,

Welcome to send me by Inquiry or by Email !

Welcome to visit us, 1.5 Hours driving time from shanghai airport.

Related Keywords

Related Keywords

You May Also Like

You May Also Like