PVC pellet hot cut extrusion line

-

$70000.001-2 Set/Sets

-

$68000.00≥3 Set/Sets

- Transportation:

- Ocean

- Port:

- taicang , shanghai , ningbo

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 5sets per month |

|---|---|

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean |

| Port: | taicang ,shanghai ,ningbo |

UPVC PVC plastic hot cut pelletizing machine

PVC UPVC plastic pelletizing granulating machine line for sale

Description:

This PVC plastic pelletizing machine is design specializes for recycling the recycled washed plastic PVC plastic flakes/scraps, such as PVC pipe flakes/scraps, PVC sheet flakes/scraps etc.

After processing techniques such as feeding, heating, melt, cutting, cooling etc., the final products are PVC plastic pellets/granules that can be to produce new PVC plastic products.

Features

The screw is made of high tool steel 38 CrMoALA, Special screw combination Euro-style rectangle barrel, reflux refrigeration channel optimized and disposed, which makes temperature difference in D areas smaller.

Innovated design of heater-tightened style insures high efficiency of heat transfer and high longevity of heater.

Working Flow of PVC plastic pelletizing Recycling machine:

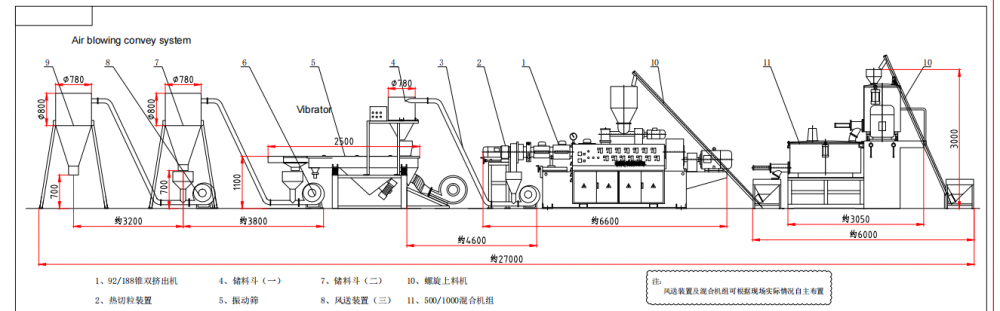

Screw feeder → Conical twin extruder → Cutting → Blower → Storage hopper → Blower → Storage hopper → Electric control panel

Screw feeder: the first step of the pelletizing recycling machine, Pvc plastic flakes/scraps conveyed into the hopper through screw, the screw connect sensor to detect the material in hopper, once the flakes are full in hopper, the screw will stop; and once empty, the screw feeder will begin working.

Extruder: to plasticization and degassing, a specialized single screw extruder applied to melt the pre-compacted material. The plastic scraps will well melted, plasticized in the first stage extruder, and the plastic will be extrude by the second stage extruder. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

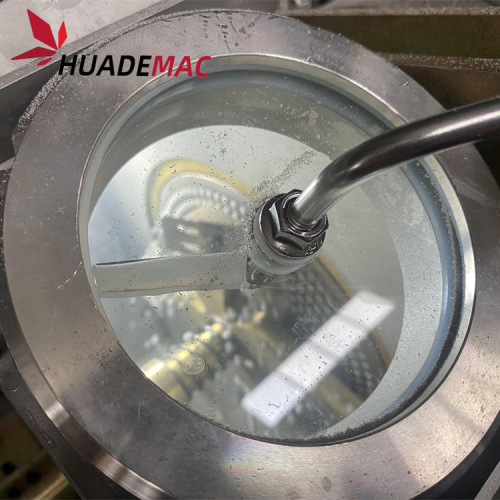

Cutting pelletizing: supplied with speed steel and hard alloy steel cutting blades for reliable performance. Compact structure allows less maintenance.

Blower and hopper: to cooling the PVC pellets and storage the pellets.

Related Keywords