Waste plastic film granules making machine

-

USD480001-2 Set/Sets

-

USD46000≥3 Set/Sets

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 50 Days

- Transportation:

- Ocean

- Port:

- Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | china |

|---|---|

| Productivity: | 300-350kg |

| Supply Ability: | 10set per month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE |

| HS Code: | 84778000 |

| Transportation: | Ocean |

| Port: | Shanghai |

Product Description

Product Description

Products Description

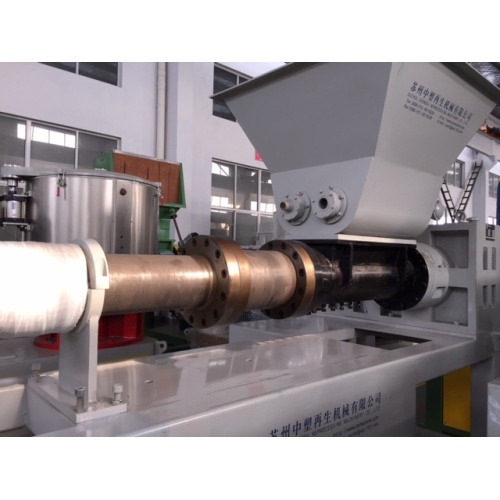

plastic pelletizing machine/granulating machine/plastic granulator

Special conical screw could help enhance the feeding function and drainage function effectively.

We adopt electromagnetic heating tecnology in this machines and it can help wet films rapidly plastic plastify.

There are one air outlet on the barrel and this help moisture discharge to improve the pellets’ quality.

The surface of the screw and barrel have been special treated so that the screw and barrel are wearable.

They have very good wear properties and mixing effect and the production capacity is high.

The extruder has the vacuum vented design which can exhaust the vapor or gas during the production so that the output are more stable and the pellets are more uniform.

We adopt electromagnetic heating tecnology in this machines and it can help wet films rapidly plastic plastify.

There are one air outlet on the barrel and this help moisture discharge to improve the pellets’ quality.

The surface of the screw and barrel have been special treated so that the screw and barrel are wearable.

They have very good wear properties and mixing effect and the production capacity is high.

The extruder has the vacuum vented design which can exhaust the vapor or gas during the production so that the output are more stable and the pellets are more uniform.

|

Model

|

Screw diameter(mm)

|

Screw length(mm)

|

Motor power(kw)

|

Output(kg/h)

|

|

220/150

|

220/150

|

3300

|

90/110

|

350-450

|

|

250/180

|

250/180

|

4000

|

132/160

|

500-600

|

Details Images

Screen changer

Dewatering machine

Vibrating sieve

Fan and Silo

FAQ

Why choose us:

1.low cost :

all the machine ,we make it ourself to reduce the cost of our customer.

2.Genuine product with excellent quality :

we choose our material very strict,

all the material come to our factory must pass the quality test

substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4.quick delivery:

the company provide just in time delivery with its streamlined supply chain

5.cost saving:

we take strong attention to every detail in the manufacturing process,

the quality control in our factory is very strict,

all defective semi-manufactures must be treated again or reject.

all the machine must be checked out ,then deivered to our customer.

all about that pushing up the price,

what we want to do is give our customer a good quality product with stable working and long lived.

1.low cost :

all the machine ,we make it ourself to reduce the cost of our customer.

2.Genuine product with excellent quality :

we choose our material very strict,

all the material come to our factory must pass the quality test

substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4.quick delivery:

the company provide just in time delivery with its streamlined supply chain

5.cost saving:

we take strong attention to every detail in the manufacturing process,

the quality control in our factory is very strict,

all defective semi-manufactures must be treated again or reject.

all the machine must be checked out ,then deivered to our customer.

all about that pushing up the price,

what we want to do is give our customer a good quality product with stable working and long lived.

Related Keywords

Related Keywords

You May Also Like

You May Also Like