PVC Artificial Marble Profile Machine/Extrusion Line

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | china |

|---|---|

| Productivity: | 200-250kg/h |

| Supply Ability: | 10set per month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE |

| HS Code: | 84778000 |

| Transportation: | Ocean |

| Port: | Shanghai |

Product Description

Product Description

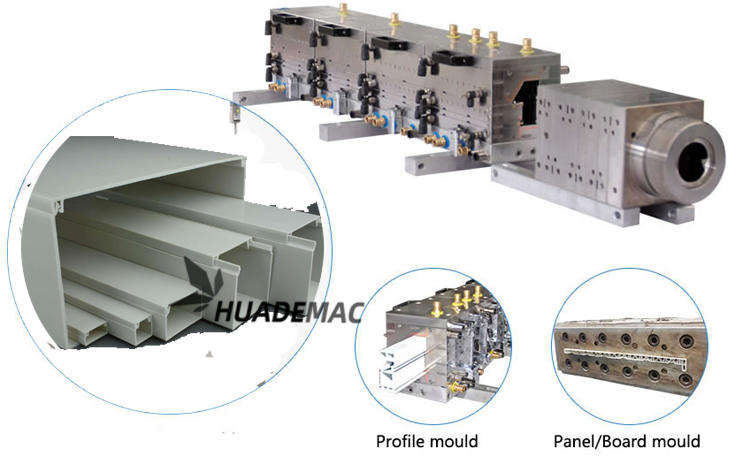

PVC profile Production Line is mainly used for many profile product.

The unit consists of conical double double extruder, mold, vacuum forming tank, haul-off machine, cutting machine, stacker and so on. And the line can be equipped with Comptroller thickening instrument or computer .

YF Series PVC profiles extrusion line is mainly used in PVC plastic steel doors and windows profile,window panels, perforated pipe threading and foam profile extrusion products.

The production line according to the different requirements of customers and cross-sectional shape of the mold, you can choose the most suitable twin-screw extruder , and equipped with the appropriate vacuum form-ing . Cuttting and other auxiliary traction.

2. Technical parameter:

|

Model

|

HD180

|

HD240

|

HD300

|

HD400

|

|

Max width of product (mm)

|

180

|

240

|

300

|

400

|

|

Extruder model

|

SJSZ55/110

|

SJSZ65/132

|

SJSZ65/132

|

SJSZ65/132

|

|

Max extrusion Capacity (kg/hr)

|

150

|

250

|

250

|

250

|

|

Extruder power (KW)

|

22

|

30/37KW

|

30/37KW

|

30/37KW

|

|

Cooling water (m3/hr)

|

5

|

7

|

7

|

8

|

Packaging & Shipping

Related Keywords

Related Keywords

You May Also Like

You May Also Like