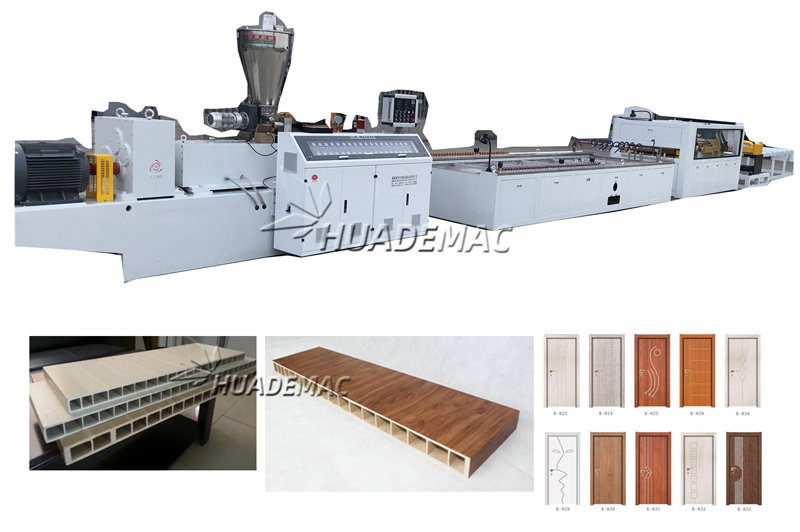

PVC WPC Hollow Door Machine

-

USD95000≥1 Set/Sets

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 350 |

| Supply Ability: | 10 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE |

| HS Code: | 84778000 |

| Transportation: | Ocean |

| Port: | Shanghai |

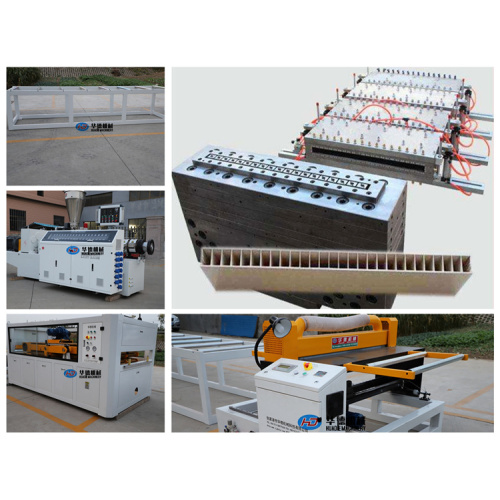

WPC/PVC Lattice/Hollow Door Board/Panel/Plate Extruder Machine

Prevent Burning SJZ80 PVC Hollow Door Panel Extruder Machine Manufacture

Constant high output

Easy to operate

Outstanding,uniform product quality

Cost-effective and flexible production

High automation

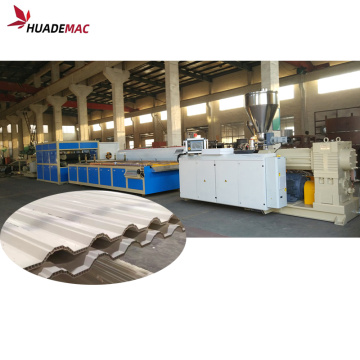

This line applies the conical twin screw extruder with imported inverter,

which provides wide adjusting range and precise temperature control.

High speed extrusion with high capacity and lower power consumption

Barrier design screw with asymmetric slotted barrel design.

PID simple automatic temperature control systems

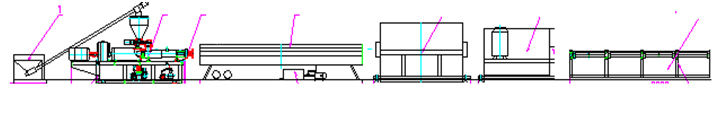

Mix the material→Feed→Extruder→Die head →Haul off→Cut→Stacking

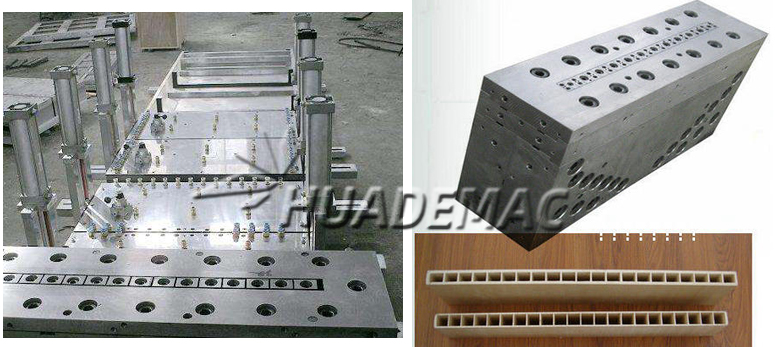

Die head

The calibration table is equipped with strong forced cooling system so that it can provide perfect calibrating effect.

Durable stainless steel material make

Three dimensionall adjustable calibration table structure

The 2 caterpillar haul off is equipped with precision gear motor and inverter, which possesses reasonable structure, strong and stable hauling force.

Fast change type of silcone pads with aluminium support

Each caterpillar is driven independently by inverter.

The cutter is equipped with PLC control system which helps to set length and provide accurate automatic cutting.

Swarfless cut structure ,good synchronization,precise length control,high quality cutting.

The stacker is covered with rubber grip blocks to prevent products from damage.

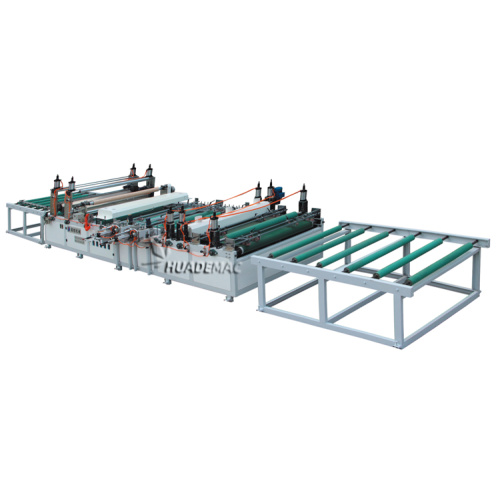

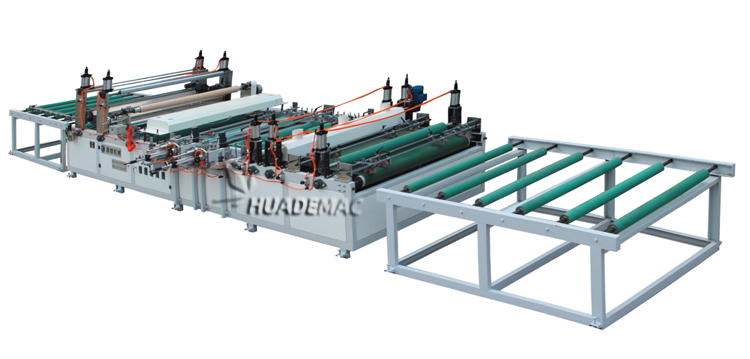

WPC PVC Board/Panel surface treatment machines hot stamping machine

Auxiliary machines for PVC/WPC Door board extrusion line

Related Keywords