PVC four cavity pipe extruding making machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 50 Days

- Transportation:

- Ocean

- Port:

- Shanghai Port

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean |

| Port: | Shanghai Port |

PVC four cavity pipe extruding making machine

Machine features

one mould 4 cavity pvc pipe extruder line can be used to prodcuce 4 pipes at one time to improve the production efficiency. machine capacity can easily reach 5.5-6.5t per day. Producing speed can reach 8-10m/min when doing pipe diameter 16mm.

|

suitable pipe diameter

|

16-32mm

|

|

traction machine

|

4 drawer fluctuation traction (caterpillar)

|

|

traction speed

|

1-10m/min

|

|

traction force

|

6000

|

Process Flow:

Screw Loader for Mixer→ Mixer unit→ Screw Loader for Extruder→ Conical twin screw extruder → Mould → Vacuum Calibration Cooling Tank → Haul-off and cutting unit → Belling machine/ Stacker → Final Product Inspecting & Packing

CHARACTERISTICS and APPLICATIONS

Four station haul-off:up-down two caterpillar tracking

Drawing speed:1-10m/min

Drawing forth:6000N

PVC four cavity pipe extruding making machine photos

Extruder

Extruder is one of the types of plastic machinery, originated in the 18th century.

According to the direction of material flow and the angle of screw center line, the extruder head can be divided into right angle head and oblique angle head.

Screw extruder relies on the pressure and shear force produced by screw rotation, which can make the material fully plasticized and evenly mixed, and then molded by die.

Die-head

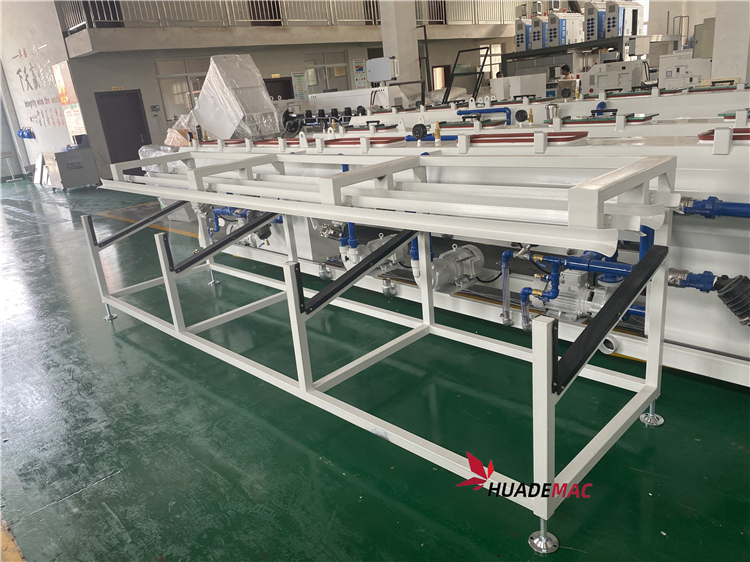

Vacuum Calibrating

Tank materials: 304 S. S.Materials

Water temperature and level controlling technology;

Haul-off & Cutter

Cutting method: Manual/Automatic

Cutting length: Measured by encoder or travelling switch

Up & Down Clamping: Pneumatic

Frame structure: beautiful appearance, safe operation

Stacker

The height is adjustable

Stainless steel 304 as touching material

Discharge driving by air cylinder

Packaging of PVC four cavity pipe extruding making machine

Exhibition of PVC four cavity pipe extruding making machine

Related Keywords