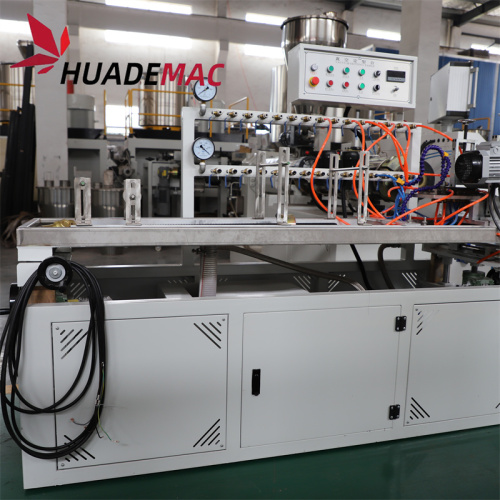

High quality extrusion line for PC PS led light profile

-

$26000.001-2 Set/Sets

-

$25000.00≥3 Set/Sets

- Transportation:

- Ocean

- Port:

- shanghai

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | CFR,CIF,FOB |

| Transportation: | Ocean |

| Port: | shanghai |

Brief Introduction:

A PC LED lighting diffusion profile making machine is a device used to manufacture diffusion profiles for LED lighting fixtures. These profiles are typically made from polycarbonate (PC) material and are used to distribute and diffuse the light emitted by the LEDs.

The machine consists of several components and processes. Here is a basic overview of how it works:

1. Material feeding: The machine has a hopper or feeding system where PC granules are loaded. These granules are the raw material used to produce the diffusion profiles.

2. Heating and melting: The PC granules are fed into a heating chamber or extruder. Inside the chamber, the granules are heated and melted to form a molten PC material.

3. Extrusion: The molten PC material is then pushed through a die or mold with the desired shape and dimensions of the diffusion profile. The die may have multiple cavities to produce multiple profiles simultaneously.

4. Cooling and shaping: As the molten PC material passes through the die, it is cooled down rapidly using cooling systems such as water or air. This solidifies the material and gives it the desired shape and structure.

5. Cutting and finishing: Once the diffusion profiles have solidified, they are cut to the desired length using a cutting mechanism. The edges may also be trimmed or finished to ensure smooth and precise profiles.

6. Quality control: The finished diffusion profiles are inspected for any defects or imperfections. This may involve visual inspection or automated systems to check for dimensions, surface quality, and other criteria.

7. Packaging: The final step involves packaging the diffusion profiles for shipment or further processing. They may be bundled, wrapped, or placed in containers depending on the requirements.

Overall, a PC LED lighting diffusion profile making machine automates the production process of manufacturing diffusion profiles for LED lighting fixtures. It ensures consistent quality, high efficiency, and precise control over the shape and dimensions of the profiles.

Related Keywords