Big diameter PE pipe production line

-

USD150000≥1 Set/Sets

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 50 Days

- Transportation:

- Ocean

- Port:

- Shanghai Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 1200 |

| Supply Ability: | 10 |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| HS Code: | 84778000 |

| Transportation: | Ocean |

| Port: | Shanghai Port |

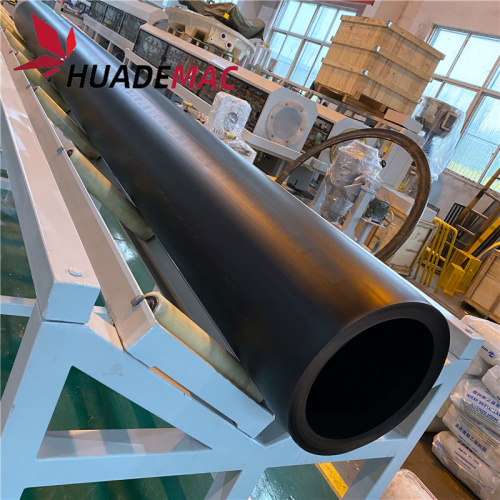

315-630mm HDPE water pipe extrusion line

315-630mm HDPE tube production line / making machine

Diameter Range (mm): 315 355 400 450 500 560 630 wall thickness by request

Main Extruder Motor Power: 328kw

Line Space Occupation: 65mx5mx3m

Capacity: 800-1000kg/h

Introduction of HDPE 315-630mm big size pipe production line

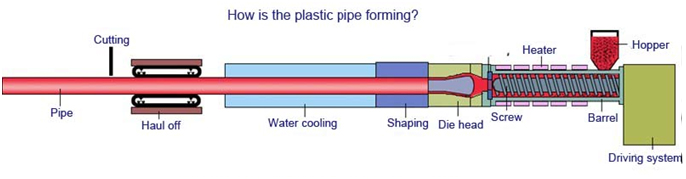

The unit consists of single screw extruder , die head, vacuum cooling tank, haul-off machine, planetary(swarf less/ chip free cutter / no dust cutter) cutting machine, winder stacker and so on.

Turn-key solution can be provided, like laser printer ,crusher, shredder, water chiller, air compressor etc. to achieve high-grade and automatic tube production.

Characteristics of PE 315-630mm Pipe extrusion line cost

- This machine is mainly used for pipe production with PE resin as raw material.

- The design of slotted feeder barrel and barrier screw can improve the plasticizing effect.

- High extrusion rate, low melt temperature and uniform temperature.

- Barrier type two pole mixing, i.e. special screw for day, slotting barrel.

- Equipped with a new type of secondary split die, with the characteristics of low temperature and low pressure extrusion: water film sizing sleeve, to ensure the high-speed production of pipes.

- The marking line can be selected to extrude to produce the pipe with color mark.

More images for PE 315-630mm pipe production line

Single screw extruder

Model :SJ900/38 extruder of HDPE315-630MM extrusion line

- Barrel and screw material: 38CrMoAlA,

-

Diameter of screw: Φ 90mm

-

Length diameter ratio of screw: 38:1

-

Driving motor power: 280kW high speed screw

- Temperature control table of OMRON

- ABB or Siemens brand inverter

- Schneider or Siemens AC contactor

- Siemens Bede motor

- Gearbox: high torque, low noise, hard tooth surface grinding reducer is equipped with external cooling circulation system

Die head and mould(including the bush,pin and calibrator)

Materials: 40Cr Steel

Structure: Spiral or Basket

Single cavity design

Single layer design

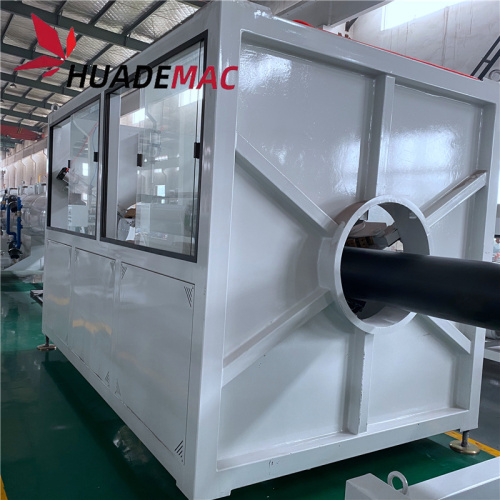

Vacuum Calibration Tank

length: 1000mm

Tank materials: 4mm 304 S. S.Materials

Double-chamber structure vacuum and cooling

Water temperature and level controlling technology

High pressure and stable water jet

Pressure protection design

6 caterpillar Haul-Off machine :

ABB Frequency motor driving

Upper and lower caterpillar is driven separately by the frequency inverter

Fast change type pads

High friction fact and anti-wear out silicon rubber Pads

Metering counter

Cutter:

Non-dust cutter, Blade rotates around pipe and cut off pipe with smooth surface.

Synchronous control

Cast aluminium fixture unit

High Quality Alloy Blades

Smooth Cutting surface

Servo motor Synchronous control

Stacker

Stainless steel 304 as touching material

Discharge driving by air cylinder

Related Keywords