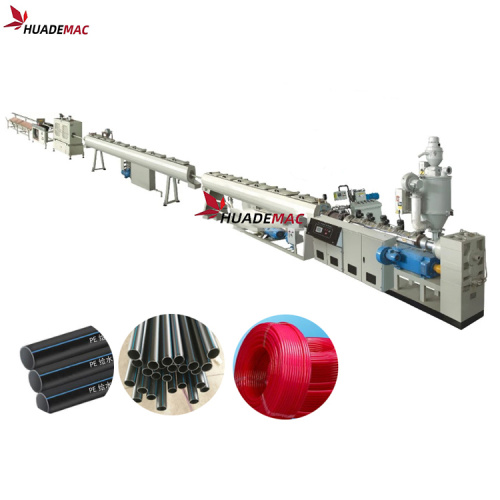

PE HDPE pipe tube production line machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai Port

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean |

| Port: | Shanghai Port |

PE HDPE pipe tube production line machine

PE/HDPE pipe production line

PE/HDPE water supply plastic pipe extrusion equipments/ making machines is mainly used to manufacture for PE plastic pipe, and GF series tube auxiliary equipments production line can also be used to process other plastic. Extruder and GF series tube auxiliary equipments production line take the features of advantages, reliability applicability together, and provide strong certification for high-quality plastic tube for customers. This production line adopts high-efficiency single-screw extruder, equipped with extrusion mould, vacuum shaping tank, spray cooling tank, haul-off, planetary cutter and controlled by PLC micro-computer system.

PE HDPE pipe tube production line machine photos

Extruder of PE HDPE pipe tube production line machine

SJ65/33 MAIN TECHNICAL PARAMETERS

1. Single screw extruder: model sj65 / 33 PE pipe making machine

2. Cylinder and screw material: 38CrMoAlA, after nitriding and grinding, the depth of nitriding layer is more than or equal to 0.6mm, which has sufficient strength, wear resistance and corrosion resistance;

3. Cylinder and screw structure: barrier screw, asymmetric slotted barrel design.

4. The gearbox is equipped with strong thrust bearing and high torque output; the gear is made of special alloy, with hard tooth surface and gear grinding process; high quality, high torque and high speed gearbox; low heat, low noise, long life and hard tooth surface reducer is equipped with external cooling system

5. Temperature control table of OMRON

6. ABB or Siemens brand inverter

7. Schneider or Siemens AC contactor

8. Siemens Bede motor

9. Diameter of screw: Φ 65mm

10. Length diameter ratio of screw: 33:1

11. Driving motor power: 55kW high speed screw

12. Gearbox: high torque, low noise, hard tooth surface grinding reducer is equipped with external cooling circulation system

13. Heating power of barrel: 5 × 4.5kw (cast aluminum heating ring)

14. Cooling power : 5 × 0.25kw forced air cooling

15. The output is 100-200kg/h

![W[}DHI9_L9]1`KGWHB5{EJV W[}DHI9_L9]1`KGWHB5{EJV](https://bsg-i.nbxc.com/product/ea/bf/63/c38dc451f9ff3f537619d79401.png)

Packaging of PE HDPE pipe tube production line machine

Exhibition of PE HDPE pipe tube production line machine

Related Keywords