Zinc Plated Cut Anchor / Weld Anchor

- Payment Type:

- L/C, T/T, D/P, Paypal

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | KUNSHAN JIANGSU CHINA |

|---|---|

| Supply Ability: | 50Ton/MONTH |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO CE SGS |

| HS Code: | 731815 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo |

Footstone: Concrete & Natural Hard Stone

Material: Steel, Stainless Steel & Other Metal Material

Usuage: The plug expands from the products tail to ensure the inside thread will not be damaged during the installation. The body is cold forging and can be easily used with Hexagon bolts or full thread bars.

Note: The knurling on the surface of this product is to enhance the friction between product and the interface,it is designed according to different construction requirement. The enclosed load carrying capacity data of this product is under the test condition of 280-330kgs/cm2 of the concrete intensily, and the max security load carrying capacity should not exceed 25% of the standard gauge.

Purpose: It can be used for welding pieces, By the special designed plug for ensuring the expansion.

| Size | Bit Dia | Thimble Bit Dia | Bore Dia | Internal Depth | Max Tension(Kgs) | ||||

| M6(W1/4) | 10.5 | 30 | 10.5 | 30 | 950 | ||||

| M8(W5/16) | 12.0 | 35 | 12.0 | 35 | 1300 | ||||

| M10(W3/8) | 14.0 | 40 | 14.0 | 40 | 1600 | ||||

| M12(W1/2) | 17.0 | 50 | 17.0 | 50 | 2600 | ||||

| M16(W5/8) | 21.7 | 60 | 21.7 | 60 | 3400 | ||||

| M20(W3/4) | 25.4 | 80 | 25.4 | 80 | 5400 | ||||

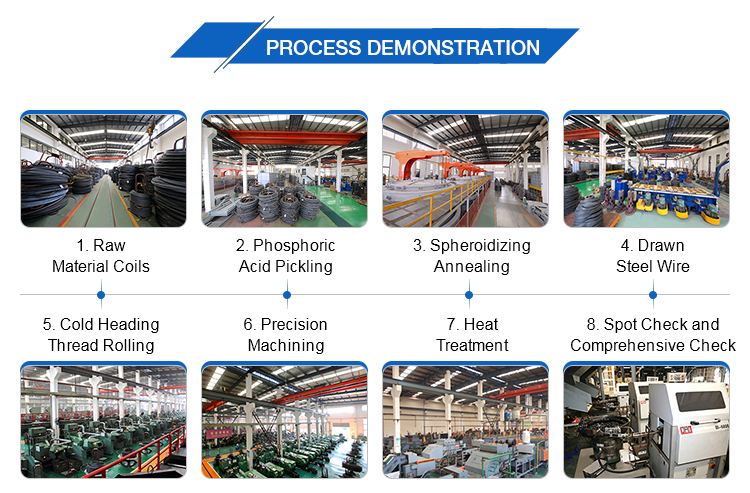

We have Magnetic Powder Detector, Material Testing Machine, Metallographic Microscope, such testing instruments, guarantee product high quality and beautiful appearance.The quality control is strictly performed from buying raw materials in warehouse to different machining procession and to final packing.

First, we have our own High-precision Digital Machining center for mould making in special Mould Workshop, excellent mould make product beautiful appearance and its size accurately.

The second, we adopt blasting procession, removing Oxidation surface, make the surface to be bright and clean and uniform and beautiful.

Related Keywords