Screws Carbon Steel Hot Dip Grade 10.9

- Payment Type:

- L/C, T/T, D/P, Paypal

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | KUNSHAN JIANGSU CHINA |

|---|---|

| Supply Ability: | 50Ton/MONTH |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO CE SGS |

| HS Code: | 731815 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo |

Our range of product:

BOLTS: hex bolts, heavy hex bolts, hex flange bolts, carriage bolts, wheel bolts, stud bolts, square head bolts, T bolts, eye bolts, U bolts, hook bolts

NUTS: hex nuts, heavy hex nuts, hex flange nuts, nylon insert lock nuts, cap nuts, slotted nuts, rivet nut

WASHERS: flat washers, spring washers, lock washers

SCREWS: machine screws, self tapping screws, set screws, hex socket head cap screws, wood

screws, self drilling screws

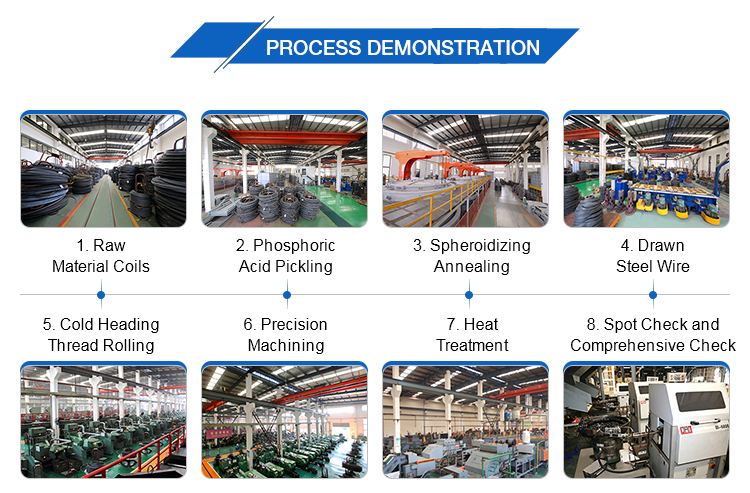

We have Magnetic Powder Detector, Material Testing Machine, Metallographic Microscope, such testing instruments, guarantee product high quality and beautiful appearance.The quality control is strictly performed from buying raw materials in warehouse to different machining procession and to final packing.

First, we have our own High-precision Digital Machining center for mould making in special Mould Workshop, excellent mould make product beautiful appearance and its size accurately.

The second, we adopt blasting procession, removing Oxidation surface, make the surface to be bright and clean and uniform and beautiful.

Related Keywords