DIN471 Stainless steel Retaining rings for shafts (external) Circlip

-

$0.02≥1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Ningbo

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | KUNSHAN JIANGSU CHINA |

|---|---|

| Supply Ability: | 50Ton/MONTH |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO CE SGS |

| HS Code: | 731815 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo |

Product Description

Product Description

Retaining rings work by applying a radial force against the shaft or bore, creating a secure and reliable hold. They are commonly used in automotive, aerospace, and industrial applications, as well as in consumer products such as bicycles and power tools.

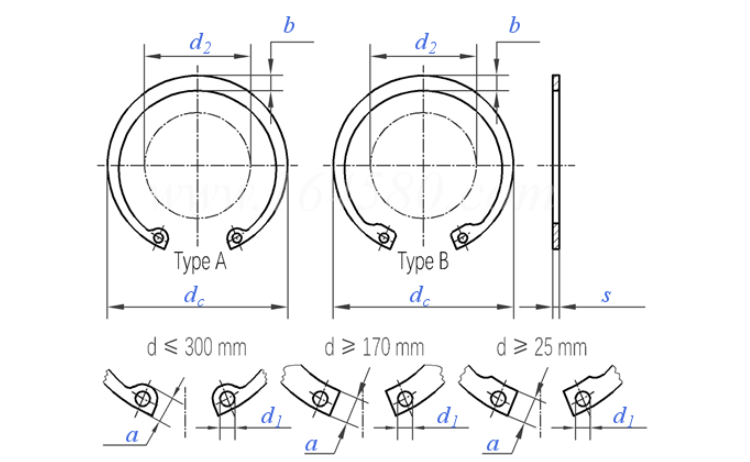

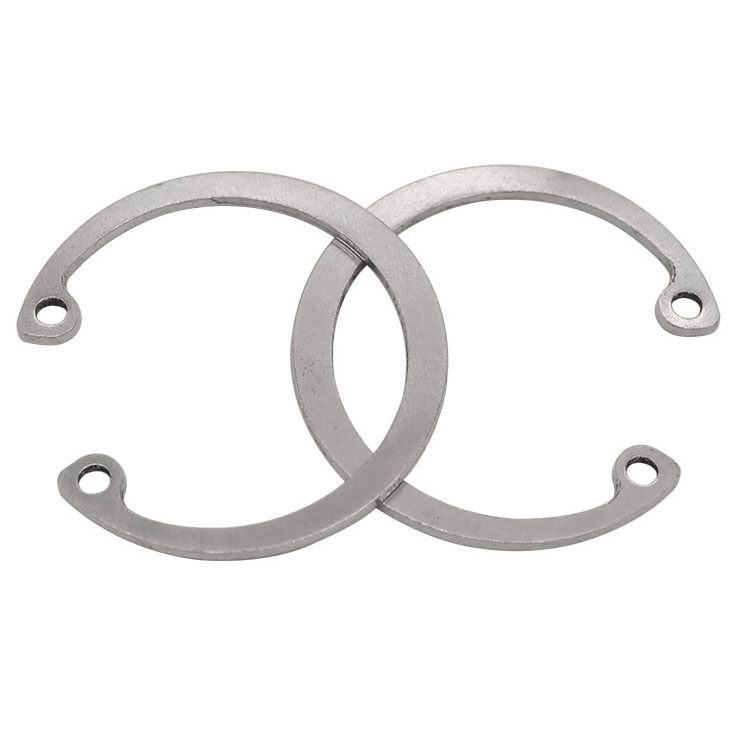

There are two main types of retaining rings: internal and external. Internal retaining rings fit inside a bore or housing, while external retaining rings fit over a shaft or pin. Both types are available in various configurations, including tapered, spiral, and constant section.

There are two main types of retaining rings: internal and external. Internal retaining rings fit inside a bore or housing, while external retaining rings fit over a shaft or pin. Both types are available in various configurations, including tapered, spiral, and constant section.

DIN472 Internal Retaining Snap Rings for Bores C shaped Metal Spring Lock Washer Clamp With Holes

Main Products

Certifications

Testing Laboratory

We have Magnetic Powder Detector, Material Testing Machine, Metallographic Microscope, such testing instruments, guarantee product high quality and beautiful appearance.The quality control is strictly performed from buying raw materials in warehouse to different machining procession and to final packing.

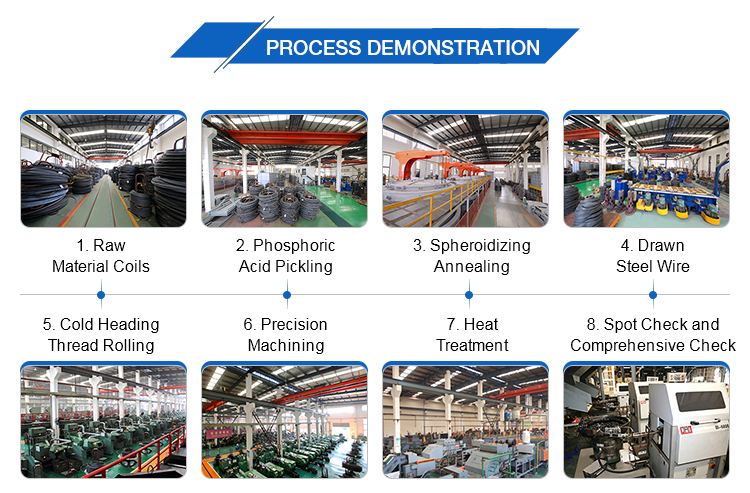

Production Process

First, we have our own High-precision Digital Machining center for mould making in special Mould Workshop, excellent mould make product beautiful appearance and its size accurately.

The second, we adopt blasting procession, removing Oxidation surface, make the surface to be bright and clean and uniform and beautiful.

Related Keywords

Related Keywords