wire rope clamp DIN741 Wire Rope Clips

-

$0.03≥1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | KUNSHAN JIANGSU CHINA |

|---|---|

| Supply Ability: | 50Ton/MONTH |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO CE SGS |

| HS Code: | 731815 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Ningbo |

Wire rope clamps, also known as cable clamps or wire rope clips, are used to connect the ends of wire ropes together or to secure the rope to an anchor point. They are commonly used in a variety of applications, such as in construction, marine, and industrial settings.

The basic design of a wire rope clamp consists of a U-shaped bolt, a saddle, and two nuts. The U-shaped bolt is placed around the wire rope, and the saddle is placed on top of the rope, with the two nuts threaded onto the ends of the bolt. As the nuts are tightened, the saddle compresses the wire rope against the U-bolt, creating a secure connection.

When selecting wire rope clamps, it is important to choose the right size and type for the application. The size of the clamp should match the diameter of the wire rope, and the type of clamp should be selected based on the application requirements, such as the load capacity and environmental conditions. It is also important to follow the manufacturer's instructions for proper installation and use of the clamps to ensure safe and effective operation.

| Product | stainless steel DIN741 wire rope clips in stock |

| Specification | M3-M64 |

| Material | Carbon steel4.8grade,8.8grade,10.9grade,12.9grade; stainless steel202,304,316,316L;Brass |

|

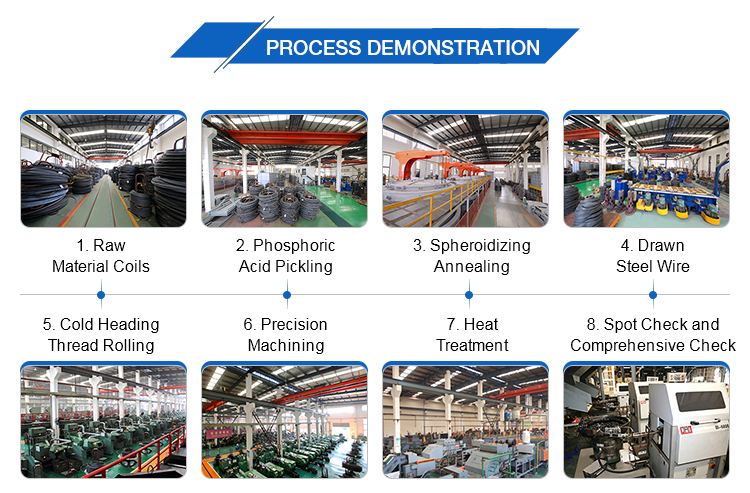

Productive Process |

wire rod→Anneal→Acid cleaing→Draw wire→molding and rolling thread→Heat treatment→Surface treat →Packing

|

| Surface treat |

Plain,Black oxide,Blue white zinc,Yellow zinc,Hot dip galvanized,Copper plating,Gold plating,Chromium Plating.

|

| Quality Control | Raw material inspect→process monitoring→Product test→Packaging check |

| Certification | ISO9001:2008 CE cert ROHs |

| Packaging | product bulk in plastic bag→Carton box→Wood pallet |

| Application | Wind tower,Nuclear power,Railway,Automotive industry,Construction,Electronic industry |

| Delivery time | 3-30days |

| Payment Terms | T⁄T30%deposit,the balance70%when we finish all of the goods;L⁄C at sight,Western Union |

BOLTS: hex bolts, heavy hex bolts, hex flange bolts, carriage bolts, wheel bolts, stud bolts, square head bolts, T bolts, eye bolts, U bolts, hook bolts

NUTS: hex nuts, heavy hex nuts, hex flange nuts, nylon insert lock nuts, cap nuts, slotted nuts, rivet nut

WASHERS: flat washers, spring washers, lock washers

SCREWS: machine screws, self tapping screws, set screws, hex socket head cap screws, wood screws, self drilling screws

We have Magnetic Powder Detector, Material Testing Machine, Metallographic Microscope, such testing instruments, guarantee product high quality and beautiful appearance.The quality control is strictly performed from buying raw materials in warehouse to different machining procession and to final packing.

First, we have our own High-precision Digital Machining center for mould making in special Mould Workshop, excellent mould make product beautiful appearance and its size accurately.

The second, we adopt blasting procession, removing Oxidation surface, make the surface to be bright and clean and uniform and beautiful.

Related Keywords