100% cotton fire resistant fabric welding used 280gsm

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 1000 Meter

- Min. Order:

- 1000 Meter

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | 50000 meters per month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | Oeko-Tex standard 100 |

| Transportation: | Ocean,Air |

| Port: | Shanghai,, |

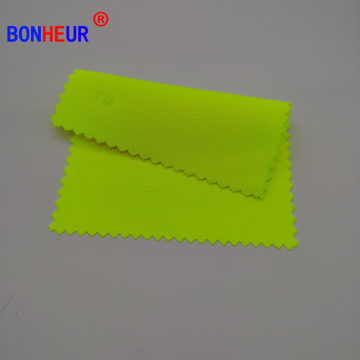

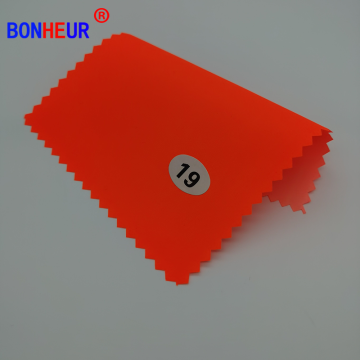

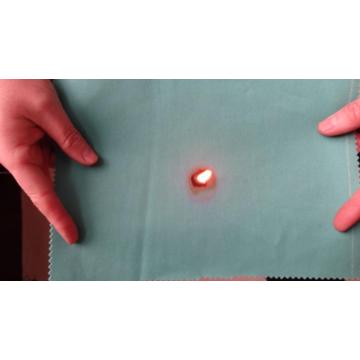

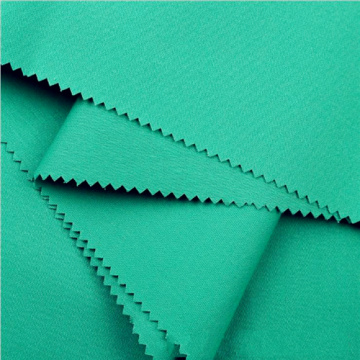

The 100% Cotton 20*16 57/58" dyed twill fabric ,The 100% cotton fire resistant fabric welding used 280gsm adopt the "Proban"production technology,which is mainly used in cotton fibers and blended fabrics, the fabrics after being finished has durability feature. It can be washed from more than 50 times. The company also has the flame retardant products with "CP" production technology, such as muti-functional cotton, T/C, CVC flame retardant, PTFE film, acid and alkali resistant, radiation protection, water and oil proofing etc.

Flame retardant properties of protective fabrics meet the standards of EN ISO 11611, EN 11612, EN14116, NFPA2112, GB 8965-2009, ASTM6413, antistatic properties meet the standards of EN1149-1, EN1149-3, GB12014, oil resistance and water resistance meet the standards of AATCC118, AATCC130, AATCC22, acid and alkali resistance meet the standards of EN368, EN12012, fluorescence can meet the standards of EN20471,The knitting flame retardant can reach CFR1616 and CFR1615

| ITEM | FR280 |

| COMPOSITION | 100 PCT COTTON , RING SPUN YARN TYPE , CARDED |

| CONSTRUCTION | 20*16 128*60 |

| WIDTH | 58/59" |

| FINISHED WEIGHT | 280GSM |

| WEAVING TYPE | 3/1 Twill |

| WEAVING METHOD | WOVEN BY AIR-JET LOOMS OR RAPIER LOOMS |

| DYEING TYPE | CONTINUOUS DYEING (SOME AREA IT CALLED PAD DYEING) |

| DYESTUFFS | ENVIRONMENTAL DYESTUFFS , REACTIVE DYES |

| FABRIC EFFECT | DRILL |

| SPECIAL FINISHING | SUPER SOFT FINISHING, IRON FREE ETC. |

| MOQ | 3000MTRS PER COL, MAKE TO ORDER |

Our poly cotton fabric bright spot:

1. RS yarn to make better strength.

2. Continuous dyeing to make good coincidence of each color.

3. Woven by rapier loom or airjet loom, quality will be much better than shuttle loom quality.

4. For uniforms, we are adopting vat dyestuffs to keep a good colorfastness.

5. we can supply different special finishing effects for various demand, such like soften finishing, stiffening,

easy care, 3M finishing, flame retardant finishing, water proof etc.

Service we can supply:

1. Small quantity of each col be acceptable with small additional charges.

2. Special construction be acceptable with special weaving of our factory.

Related Keywords