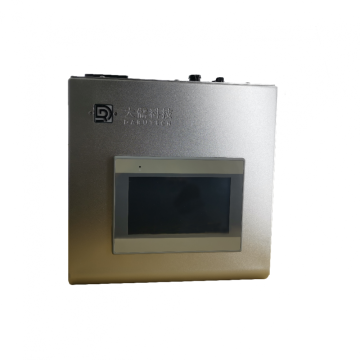

Force Control System With Plastic

Your message must be between 20 to 2000 characters

Contact Now

The

force control system for grinding and polishing has the advantages of

flexibility, fast response speed, instantaneous adjustment, suitable for

any angle in three-dimensional space, and is not affected by component

force. It is suitable for any brand robot, high versatility, suitable

for different grinding and polishing work scenarios.

The force control system is suitable for different grinding and polishing work scenarios.

The force control system is dedicated to robot polishing and grinding.

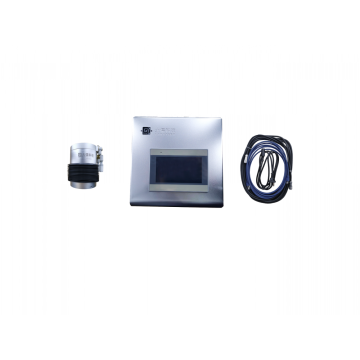

The

force control system currently has multiple models, suitable for

different grinding and polishing work scenarios. The force control

system flexibly controls the grinding process, which can be adjusted

instantaneously according to the tolerance of the workpiece and the

slight position offset. The size of the holding force is within the set

range, ensuring the consistency of the surface effect. The perfect

integration with the robot can significantly reduce the commissioning

threshold. The robot only needs to control the grinding path, and the

force control system controls the grinding force, so that the grinding

force can be quantified. For sheet metal, stamping, plastic parts, etc.

with large tolerances or deformations, It can ensure the same effect and

high mass production achievability.

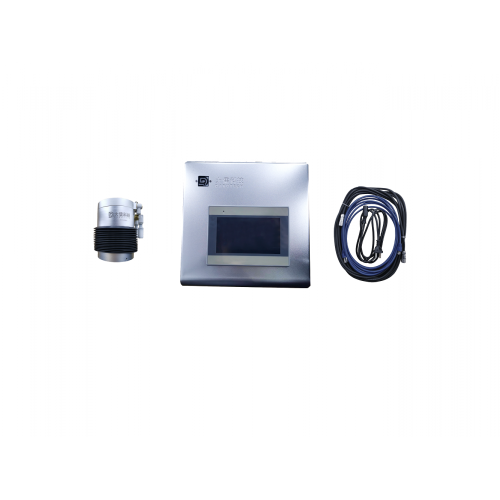

Founded in 2020, Daru Technology (Suzhou) Co., Ltd. is located in the Suzhou Industrial Park of the Yangtze River Delta. It is composed of a professional team led by a postdoctoral researcher. It takes 4 years to develop and design a power control system (for robot polishing and polishing), which fills the domestic gap. At present, it mainly provides enterprises with automated grinding and polishing systems, automated loading and unloading systems for research and development, design, sales and perfect after-sales service.

|

Basic parameters |

||||

| Product specification | DFC311 | DFC481 | DFRC481 | DFRC1201 |

|

Maximum force (n) (horizontal direction) |

31 | 48 | 48 | 120 |

| Adjustable range of mill speed(r/min) | - | - | 4000~10000 | 4000~10000 |

| Effective stroke(mm) | 30 | 30 | 30 | 30 |

| Contour diameter(mm) | Ø124 | Ø124 | Ø124 | Ø124 |

|

Outline height (mm) (including zero stroke of flange) |

174 (Mill size not included) |

174 (Mill size not included) |

287 (Including mill size) |

287 (Including mill size) |

| Net weight(Kg) | 3.1 | 3.3 | 4.6 | 4.6 |

| control accuracy(N) | 1 | 2 | 2 | 2 |

| response time(ms) | 10 | |||

|

Air consumption (L/min) |

5~10 | |||

| communication interface | Standard:ProfiNet , TCP/IP | |||

Related Keywords