single layer ctp plate js

- Transportation:

- Ocean, Land, Air

- Port:

- ShangHai Port, Ningbo Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | Strong |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | ShangHai Port,Ningbo Port |

Domestic demand

After years of development, the technology and quality of single Layer CTP plate JS technology has become increasingly mature, and is now in the stage of large-scale installation and popularization. Compared with the traditional plate making process, ink-jet CTP plate making eliminates the process of film, manual plate making, printing plate, dirty repair and so on. The whole pre-press process is a digital process, which improves the speed and quality, saves the price of film, and truly realizes the cost reduction.

However, a suitable Single Layer Ctp Plate Kit system needs to start from the characteristics of packaging and printing and solve a series of problems that may occur in packaging and printing enterprises to meet the needs of packaging and printing enterprises. When Single Layer Ctp Plate Length technology enters packaging and printing enterprises, the following problems need to be solved:

Check customer documents before packaging printing, as well as large plate and trap printing

For external customer documents, due to the complex and diverse production software versions and a variety of processing effects, will bring error opportunities to the prepress output, the process system needs to have a variety of error check mechanism, the possibility of error and loss to the enterprise to minimize. At the same time, packaging enterprises in the traditional production process, manual check trap printing, manual big plate, time-consuming and laborious, and low efficiency. The Single Layer Ctp Plate Layer system is required to assist the prepress personnel to solve the problems of trapping, plate-forming, ink conversion, and pre-flying in prepress processing.

TECHNICAL DATA

|

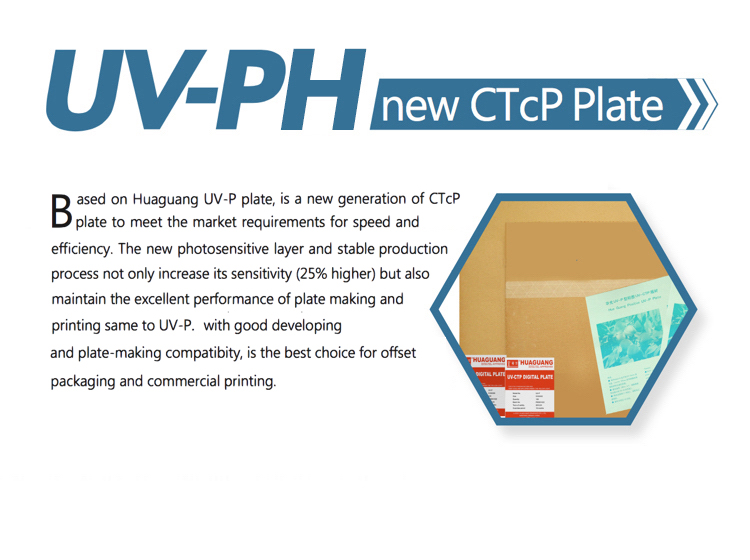

UV-PH HIGH SENSITIVITY POSITIVE CTcP PLATE |

|

|

Plate Type |

UV-PH type UV-CTP plate, also used as high sensitivity PS plate. |

|

Application |

Commercial sheetfed and rotary press printing |

|

Substrate |

Electrochemically grained and anodized aluminum |

|

Gauge |

0.15/0.20/0.25/0.30/0.40mm |

|

Maximum width |

1320mm |

|

Spectrum scope |

350-460nm UV light, especially 400-410nm UV laser |

|

Sensitivity |

40±5 mw(Cron UV-4632CI platesetter Parameter 1000 rpm) |

|

Safe light |

UV filtered or Yellow light |

|

Coating color |

Blue-Green |

|

Dot reproduction |

2-98% @ 250 lpi |

|

Applicable platesetter |

main UV-CTP platesetters such as Cron,luscher,Amsky,basysPrint. |

|

Run length |

Above 100,000,which may vary against the different press, ink and stock condition |

|

Developer |

Common positive offset plate developer |

|

Development |

Conductivity: min 55ms, max 65ms Temperature: 20-25°C PH 13.00-13.40 |

|

Packaging |

0.15mm 100 pieces/box 0.25/0.30mm 50 pieces/box if length <1030mm; 30 pieces/box if length ≥1030mm; 25 pieces/box if the area > 1m2 |

|

Shelf life |

18 months when stored in a light-free area away from excessive cold, heat and high humidity |

|

Transport and storage |

Store plates at in their packaging, away from excessive cold, heat or high humidity. Recommended condition is: temperature 10-26°C & RH between 40 - 70%. |

Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate

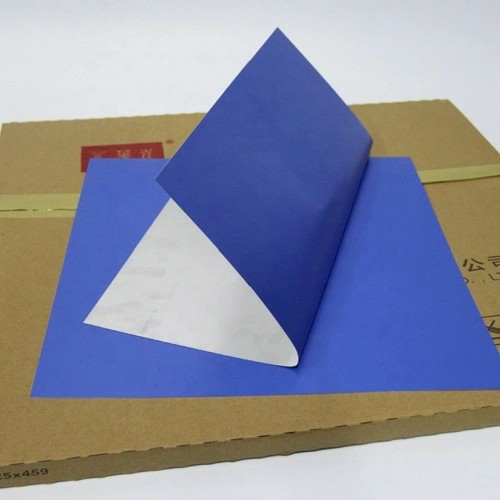

PACKING WAY

Related Keywords