processless ctp plate OEM

- Transportation:

- Ocean, Land, Air

- Port:

- ShangHai Port, Ningbo Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | Strong |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | ShangHai Port,Ningbo Port |

1. The printing accuracy requirements are not high, and the rubber plate can be used when the printing volume is not large.

2. If the text is small and the pattern is delicate, the ordinary resin version can be used.

3. Laser flat screen printing plate can be used for high screen printing and large printing volume, which is more durable.

In addition, the different characteristics of the plate also have a certain impact on the printing quality and cost. The following elements need to be considered when selecting:

Ink release: The normal ink transfer volume should be maintained above 80%, and the larger the transfer volume, the better the printing quality will be improved;

Hardness: The lower hardness of the printing plate for full-page printing, about HS35, is more suitable for printing; the printing of dots and fine characters with higher hardness, about HS40 is more suitable for printing. For general printing plates, it is more appropriate to use a hardness of about HS38.

Elasticity: High elasticity and fast deformation recovery are better for full-page printing; low elasticity and slow deformation recovery are better for fine character and dot printing, which can better maintain the performance of the sharp edge of the printing plate.

Abrasion resistance: Consider the life of the plate.

Corrosion resistance: It is resistant to the erosion of ink and lotions, which directly affects the service life of the printing plate.

The use of flexo plates in flexo printing can bring about improvements in print quality. For companies, this helps them develop delicate cartons with higher quality requirements and higher profit margins. In the production of flexographic resin plates, plate-making exposure control is the key. The difference in exposure time will make the hardness, corrosion depth and elasticity of the produced flexo resin plate have great differences. Too long exposure time and overexposure will cause the graphics and text on the printing plate to be lost or not washed out, and the printing plate will also be deformed, hardened and brittle; Washed out during plate washing.

|

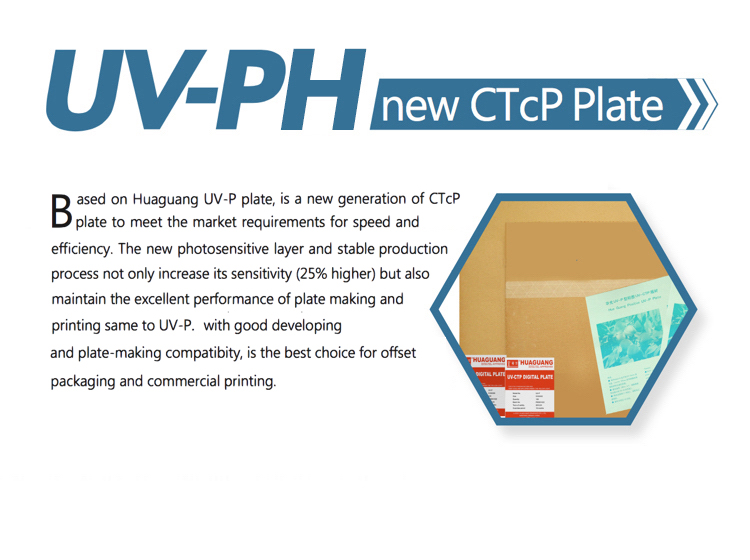

UV-PH HIGH SENSITIVITY POSITIVE CTcP PLATE |

|

|

Plate Type |

UV-PH type UV-CTP plate, also used as high sensitivity PS plate. |

|

Application |

Commercial sheetfed and rotary press printing |

|

Substrate |

Electrochemically grained and anodized aluminum |

|

Gauge |

0.15/0.20/0.25/0.30/0.40mm |

|

Maximum width |

1320mm |

|

Spectrum scope |

350-460nm UV light, especially 400-410nm UV laser |

|

Sensitivity |

40±5 mw(Cron UV-4632CI platesetter Parameter 1000 rpm) |

|

Safe light |

UV filtered or Yellow light |

|

Coating color |

Blue-Green |

|

Dot reproduction |

2-98% @ 250 lpi |

|

Applicable platesetter |

main UV-CTP platesetters such as Cron,luscher,Amsky,basysPrint. |

|

Run length |

Above 100,000,which may vary against the different press, ink and stock condition |

|

Developer |

Common positive offset plate developer |

|

Development |

Conductivity: min 55ms, max 65ms Temperature: 20-25°C PH 13.00-13.40 |

|

Packaging |

0.15mm 100 pieces/box 0.25/0.30mm 50 pieces/box if length <1030mm; 30 pieces/box if length ≥1030mm; 25 pieces/box if the area > 1m2 |

|

Shelf life |

18 months when stored in a light-free area away from excessive cold, heat and high humidity |

|

Transport and storage |

Store plates at in their packaging, away from excessive cold, heat or high humidity. Recommended condition is: temperature 10-26°C & RH between 40 - 70%. |

Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate

Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate

Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate

Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate

Manufacturer ctcp printing plates uv ctp plate ctcp printing offset plate

Related Keywords