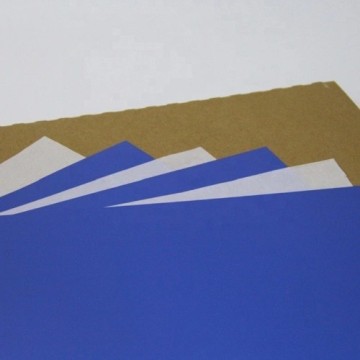

conventional postive ps plate for sale

- Transportation:

- Ocean, Land, Air

- Port:

- ShangHai Port, Ningbo Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | Strong |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | ShangHai Port,Ningbo Port |

Now we talk about the processing technology and method: conventional postive PS plate for sale processing includes: engraving; Bending; Punch; Groove; Adhesive; Polishing printing, etc. Conventional Postive Ps Plate Example can be cold and hot bending; Also can be molded and blister.

Conventional Postive Ps Plate Extension processing products are: mechanical and electrical equipment panel,PC board window,PC board cover shell,PC board baffle,PC board shield,PC transparent door panel. Electrical cabinet protection cover.

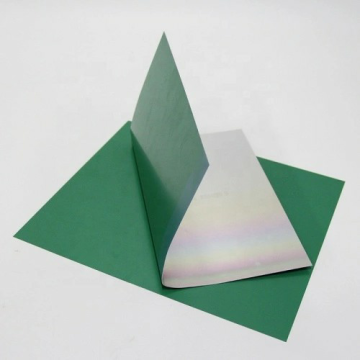

Baking plate Baking plate is the printing plate after exposure, development, decontamination and repair, after coating the surface with protective liquid, put it in the plate baking machine, and bake it at a constant temperature of 230-250 ℃ for 5- 8min, take out the printing plate, after natural cooling, develop it again with the developer, and clear the remaining protective liquid on the plate, and finally dry it with hot air. By baking the plate, the endurance of the PS plate can be increased by 50,000-100,000 impressions.

Ink extraction Ink extraction is to coat the developed black ink on the graphic part of the printing plate, which can increase the adsorption of the graphic photosensitive layer to the ink, and also facilitates the inspection of the printing quality.

Gluing Gluing is to coat a layer of gum arabic on the surface of the printing plate, which makes the hydrophilicity of the non-graphic blank

|

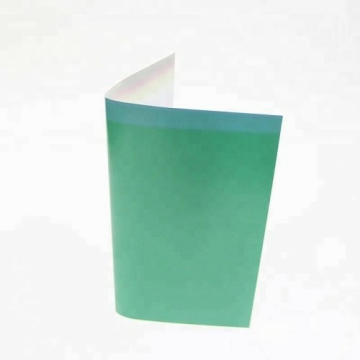

YP-II POSITIVE PS PLATE |

|

|

Plate type |

Positive |

|

Application |

Commercial sheetfed and rotary press printing |

|

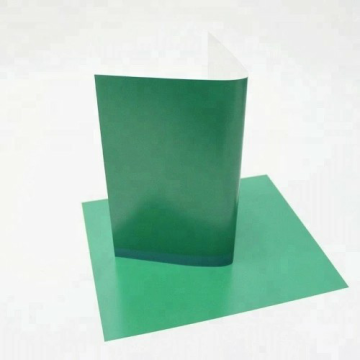

Substrate |

Electro-chemically grained and anodized lithographic aluminum. |

|

Gauge |

0.15/0.25/0.30/0.40mm |

|

Maximum width |

1320mm |

|

Spectrum scope |

350-420nm |

|

Sensitivity |

130-150mj/cm2 |

|

Safe light |

UV filtered or Yellow light |

|

Coating color |

Green |

|

Dot reproduction |

2%-98%@ 200lpi Depend upon capability of imaging device |

|

Run length |

Above 100,000 |

|

Developer |

Huaguang PD developer (concentrated solution), |

|

Development |

1 liter can process 15 sqm Developer dilute ratio: 1:4(machine)-1:6(hand) Developing Temperature: 24-26℃ Developing Time: 20-30secs |

|

Packaging |

0.15mm 100 pieces/box 0.25/0.30mm 50 pieces/box if length <1030mm; 30 pieces/box if length ≥1030mm; 25 pieces/box if the area > 1m2 |

Related Keywords