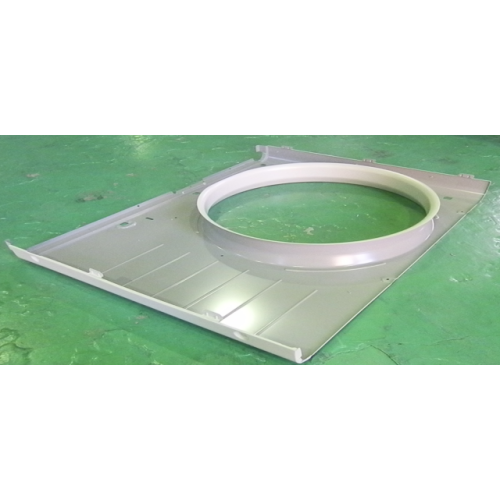

Precision cold stamping die

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

1. Staming die material: CR12MOV, SKD61, SKD11;

2. Metal parts material: SPCC, SUS304, SECC, AL;

3. Offer 2~5 first trial samples.

1. Simulations for part;

2. Stamping die precision: 0.02mm;

3. Stamping die design: 2D&3D;

4. ISO9001: 2000.

1. Stamping die life: 50000~500000shots;

2. Cavity: Single/multiple;

3. Established in 2003.

We usually quote the stamping die cost according to the product drawing or sample from customer, the basic essential information which need customer to offer and what we can supply is indicated in the following table, for your reference.

Mold base: LKM, HASCO, and so on. All native files and IGES, DXF, STEP, STL, etc. Files can be received.

Mould hot runner: HASCO, YUDO, EWIKON

3)The moulds & products are related to home appliance, automobile, electronic products, articles of everyday, medical devices, health care proudcts, etc.

4)Have the injection molding dept. Which can make us guarrantee the mould trial and the batch production of the plastic parts.

5)ISO9001: 2000 certified by SGS.

2. Metal parts material: SPCC, SUS304, SECC, AL;

3. Offer 2~5 first trial samples.

1. Simulations for part;

2. Stamping die precision: 0.02mm;

3. Stamping die design: 2D&3D;

4. ISO9001: 2000.

1. Stamping die life: 50000~500000shots;

2. Cavity: Single/multiple;

3. Established in 2003.

We usually quote the stamping die cost according to the product drawing or sample from customer, the basic essential information which need customer to offer and what we can supply is indicated in the following table, for your reference.

Mold base: LKM, HASCO, and so on. All native files and IGES, DXF, STEP, STL, etc. Files can be received.

Mould hot runner: HASCO, YUDO, EWIKON

3)The moulds & products are related to home appliance, automobile, electronic products, articles of everyday, medical devices, health care proudcts, etc.

4)Have the injection molding dept. Which can make us guarrantee the mould trial and the batch production of the plastic parts.

5)ISO9001: 2000 certified by SGS.

| Step | Item | Description |

| 1 | Quotation | We offer you the stamping die and part quotation according to your details (drawing or sample, material, quantity, weight). |

| 2 | Order | If our quotation is competitive, you will place the order. |

| 3 | Drawing design | We design the mould structure drawing according to your product drawing or sample, then send to you for confirmation. |

| 4 | Mould making | After your confirmation of our drawing, we begin to make the moulds, during manufacturing program, we send you mould building progress with pictures every week, for you to know our process. |

| 5 | First trial | We will make the stamping die first trial on time, then send you video, picture and samples for you to confirm. |

| 6 | Quality confirm | You will confirm our stamping die quality according to sample. If you need to adjust the product structure, we can help you to change it further. |

| 7 | Delivery |

Ship the stamping die after it is completely OK, packed by wooden case. |

Related Keywords

Related Keywords