Liquid flow cooler battery cooling CNC precious processing

-

$300.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land,Air,Express |

Product Description

Product Description

Process introduction

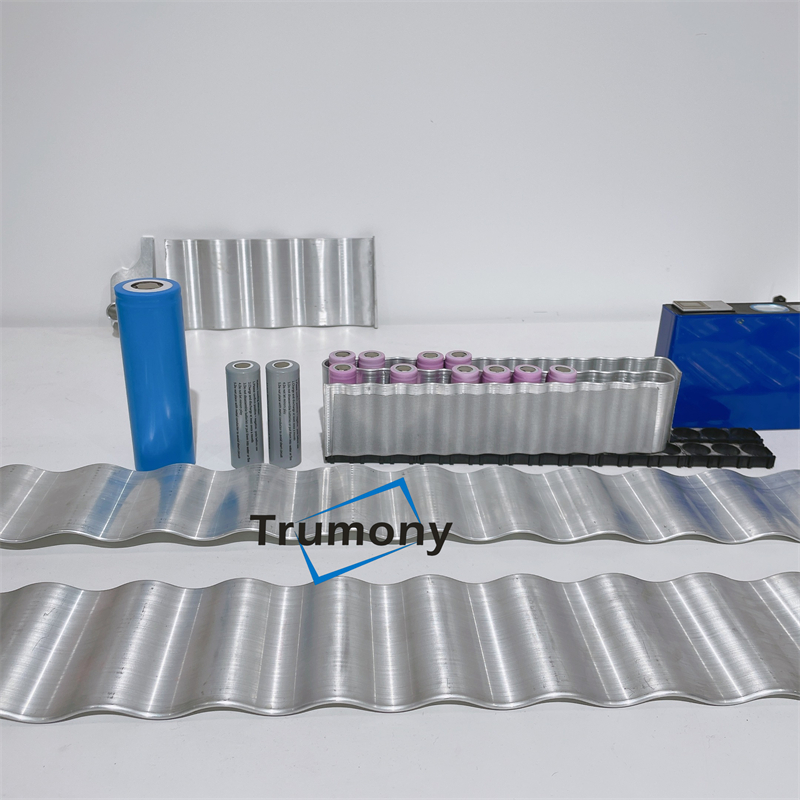

Micro-channel flat tubes are fabricated by extrusion and drawing process. Braze the collector tube and inlet/outlet ports. Then bend the flat tube according to the battery size so that the bent tube fits the battery.

Large heat exchange area with cylindrical cell and low cost of manufacture. It is the best solution for side heat exchange of cylindrical cell.

Micro-channel flat tubes are fabricated by extrusion and drawing process. Braze the collector tube and inlet/outlet ports. Then bend the flat tube according to the battery size so that the bent tube fits the battery.

Features

Spectifications

|

Cooling medium |

50% water + ethylene glycol |

|

Flow |

5L/min |

|

Simulated temperature |

18℃ |

|

Cooling medium density |

1076.46kg/m3 |

|

Viscosity |

Viscosity |

#Aluminum Water Cooling Plate, Cooling Tube For ESS, Snake Tube For ESS, snake tube for ESS,Heat Exchanger Components,

Related Keywords

Related Keywords

You May Also Like

You May Also Like