Aluminum Water Heat Pipe for ESS

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100000pcs per month |

| Supply Ability: | 1200000pcs per year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO 9001 |

| HS Code: | 7608 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

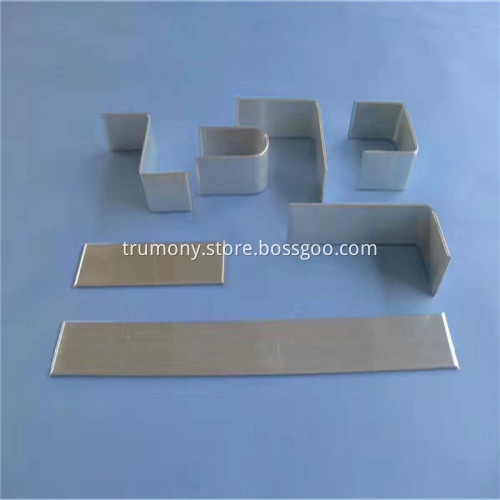

Aluminum water heat pipe for ESS

The engineering background of microchannels (microchannel heat exchangers) comes from the cooling of high-density electronic devices in the 1980s and the heat transfer problems of microelectronic mechanical systems that appeared in the 1990s. In 1981, Tuckerman and Pease proposed the concept of micro-channel heat sink; in 1985, Swife, Migliori and Wheatley developed a micro-channel heat exchanger for heat exchange between two fluids. With the development of micro-manufacturing technology, people have been able to manufacture micro-sized heat exchangers composed of channels with a hydraulic diameter of 10 to 1,000 μm. In 1986, Cross and Ramshaw developed a printed circuit micro-scale heat exchanger with a volume heat transfer coefficient of 7MW/(m3·K); in 1994, Friedrich and Kang developed a micro-scale heat exchanger with a volume heat transfer coefficient of 45MW/(m3·K). K). We also have aluminum brazing tube, aluminum grooved tube, aluminum embossed sheet, aluminum rolling sheet, aluminum ultra flat sheet and so on.

Company Introduction:

Trumony Aluminum Co.LTD build from 2006, have export over 53 countries of worldwide. Our main products are aluminum alloy cladding material, core material and other aluminum products like aluminum coil, aluminum foil, aluminum strip, aluminum radiator tube for vehicle, aluminum pipe, aluminum tube, flat aluminum micro channel tube,aluminum heat pipes etc, for automobile heat exchangers area such as radiator, intercooler, condenser, evaporator and industrial heat exchangers, like electricity power radiator, air conditioner etc.There are complete sets of modern production and testing equipment operation workshops for casting, hot rolling, cold rolling, finishing and advanced check-out for researching and testing,such as WDW-3010- micro-controlled electronic universal testing machine,CALS-2000 aluminum alloy metallographic image analysis system etc.

1.Application area:

2) 4000 series: 4043 etc

| No. | Alloy | Temper | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elogation(%) |

| 1 | 1050 | O/F/H111/H112 | ≥ 65 | ≥ 20 | ≥ 25 |

| 2 | 1100 | O/F/H111/H112 | ≥ 75 | ≥ 20 | ≥ 25 |

| 3 | 1197 | O/F/H111/H112 | ≥ 80 | ≥ 25 | ≥ 20 |

| 4 | 3102 | O/F/H111/H112 | ≥ 75 | ≥ 20 | ≥ 25 |

| 5 | 3R03 | O/F/H111/H112 | ≥ 80 | ≥ 25 | ≥ 20 |

5.Chemical Composition

| No. | Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | V | Ti |

| 1 | 1050 | ≤ 0.25 | ≤ 0.40 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | - | ≤ 0.05 | ≤ 0.05 | ≤ 0.03 |

| 2 | 1100 | ≤ 0.95(Fe+Si) | 0.05-0.20 | ≤ 0.05 | - | - | ≤ 0.10 | - | - | |

| 3 | 1197 | ≤ 0.15 | ≤ 0.20 | 0.40-0.55 | 0.10-0.20 | ≤ 0.03 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 |

| 4 | 3102 | ≤ 0.40 | ≤ 0.70 | ≤ 0.10 | 0.05-0.40 | - | - | ≤ 0.30 | - | ≤ 0.10 |

| 5 | 3R03 | ≤ 0.15 | ≤ 0.15 | ≤ 0.01 | 0.90-1.10 | ≤ 0.03 | ≤ 0.03 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 |

6.Commercial terms

| Minimum Order Quantity: | 100pcs, less quantity can negotiate |

| Price: | negotiation |

| Payment Terms: | T/T or LC |

| Supply Ability: | 1000,000 pcs per year |

| Delivery Time: | 15-30 working days after received your down payment |

| Packaging Details: | Standard export packaging |

7.Specification:

Width:5-240mm, or customized

Length:100-3000mm or customized

Thickness:1-6mm or customized

Heat conductivity:2000-200000w/m.k

Surface:Mill/ Anodize/ Powder

Our goods advantage:

It is an independent micro array of heat pipes, a heat conducting element with superconductive thermal properties, and a heat conducting element with high thermal conductivity. It has the following characteristics:

1).High thermal conductivity:

The thermal conductivity of the same metal material is more than 5000 times.

2).Large heat exchange per unit area:

It is 10 times of the traditional circular heat pipe with the same surface area.

3).High pressure.

It is more than 10 times of the traditional round heat pipe.

4).High reliability:

Multiple microchannels operate independently;

5).Surface contact:

Flat heat pipe, easy to form dry surface contact with other components, large heat exchange area

Our advantage:

1. Since 2006, we have rich experience in this industry in China;

2. Good reputation in aluminum material industry;

3. We have our own development department for new material research;

4. Good experience and cooperation with big client in the world;

5. With Certificate ISO9001-2008;

6. High performance cost ratio;

7. Fast delivery time 15-30 days for flat aluminum micro channel tube;

8. Good communication skills, and good after sells service, and understandings for customers;

FAQ

1, Q: Are you manufacturer of Composite Superconducting Aluminum water heat pipe?

A: Yes, we are established in 2006. As a manufacturer our customers are welcome to visit our factory.

2, Q: Do you accept customized orders?

A: Yes, we do. Your customized orders are always welcomed. Please kindly offer us your technical perfrmances or samples so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

3. Q: How can I get one quotation faster?

A: Pls offer details about your demands as more as possible,insulation thickness,over diameter,nominal voltage,working temperature,color,quantity,application,etc.

4. Q: If I can not offer above information,what should I do?

A: Try your best to offer more information,we will help you design suitable wires&cables.

5. Q: What is your company sample policy?

A: As one supplier,we see that sample is necessary for our both sides,our policy is to offer free sample as possible as we can,just one situation is exception,sample is with very complex structure,besides,we have no it in stock.

About sample shippment,you need to pay for the freight,usually freight collect by express.

6. Q: What is the lead time of sample?

A: There are several different situations:

Immediately when you need it if we have it in stock;

5~15 days if no stocked sample and the sample structure is not complex;

15~30 days if no stocked sample and the sample is with complex structure.

Related Keywords