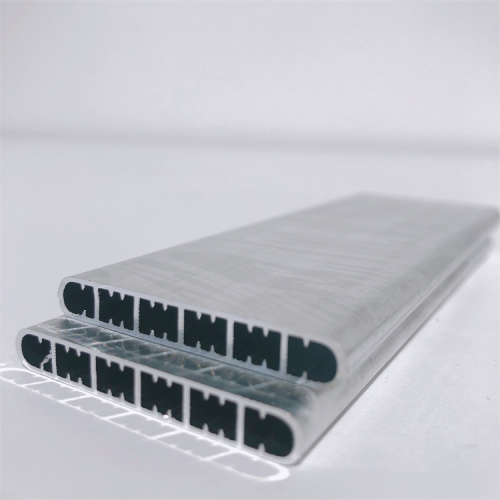

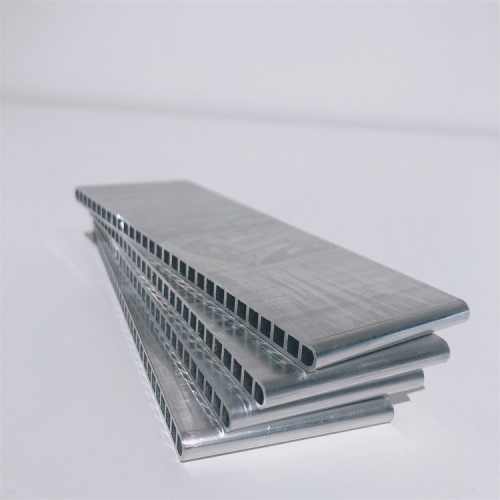

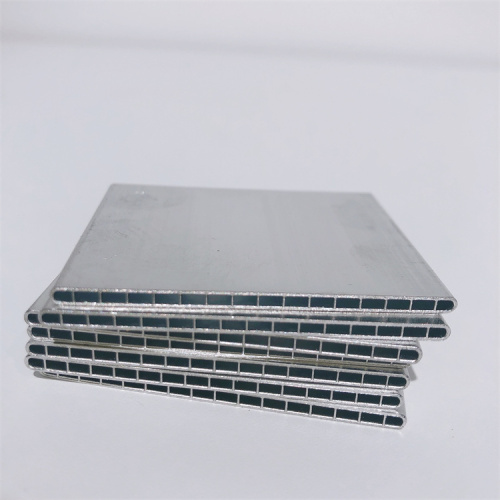

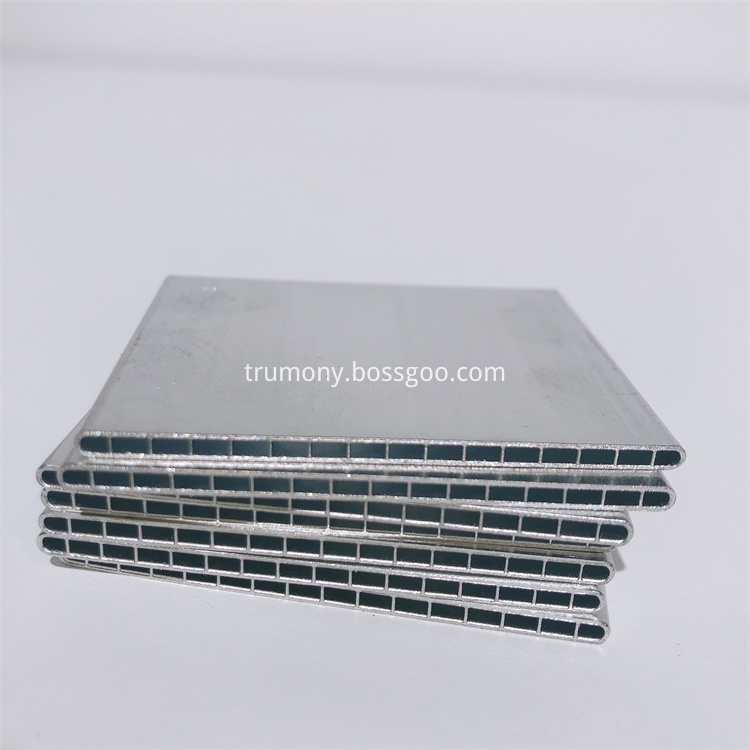

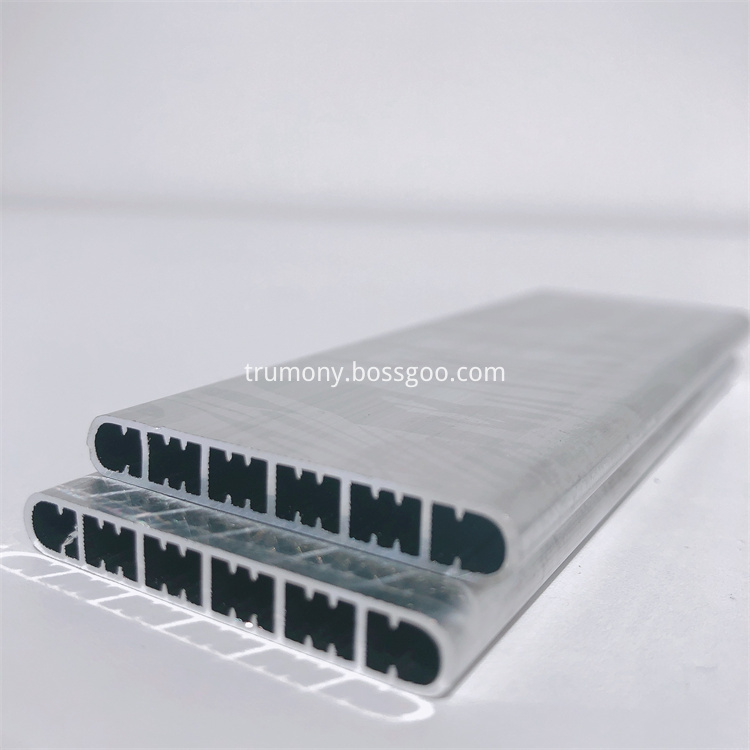

Aluminum Flat Pipes Radiator Microchannel Heat Exchanger

- Min. Order:

- 1 Ton

- Min. Order:

- 1 Ton

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Ningbo, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000tons/year |

| Supply Ability: | 10000tons/year |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | ISO9001,ISO14000 |

| HS Code: | 7607 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Ningbo,Qingdao |

Aluminum Flat Pipes Car Air Radiator Microchannel Heat Exchanger

Our aluminium tube are widely used for automobile condensers and evaporators for air conditioning systems as well as liquid lines for air conditioning, heater cores and radiators for engine cooling systems, charge air coolers and other cooling systems.With the application of the electric vehicle, the EV battery cooling system play a very important role in the automotive. so we adopt the aluminum micro channel tube for the liquid cooling components for EV, For the cylindrical batteries , we provide the snake liquid cooling tube for EV, and prismatic batteries use liquid cooling plate for EV .

Our Extrusion equipment review:

1)Surface stains and foreign body removal

2)Oxide aluminum rod surface removal

3)Eddy current inspection: It uses the equipment of Germany DB company,which can detect,identify and sort the defects of flat pipe holes and broken ribs.

4)Zinc spraying system: It uses the thermal spraying equipment of Japanese kucan company,which has a system of automatic adjustment based on speed.The surface is uniform and delicate,to make the demands of 6+/-2g,8+/-2g come true.

Package: In coil or Straight with fixed length.Packed in plywood box specialized for export.

Surface Treatment : With Zinc spraying or without Zinc spraying.

Commonly used material chemical composition

| No. | Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | V | Ti |

| 1 | 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | --- | ≤0.05 | ≤0.05 | ≤0.03 |

| 2 | 1100 | ≤0.95(Si+Fe) | 0.05-0.20 | ≤0.05 | --- | --- | ≤0.10 | --- | --- | |

| 3 | 3102 | ≤0.40 | ≤0.70 | ≤0.10 | 0.05-0.40 | --- | --- | ≤0.30 | --- | ≤0.10 |

| 4 | 3003 | ≤0.15 | ≤0.15 | ≤0.01 | 0.90-1.10 | ≤0.03 | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

Supply state and mechanical properties

| Alloy | Temper | Tensile Strength | Yield Strength | Elongation |

| 1050 | O/F/H111/H112 | ≥65MPa | ≥20MPa | ≥25% |

| 1100 | O/F/H111/H112 | ≥75MPa | ≥20MPa | ≥25% |

| 3102 | O/F/H111/H112 | ≥75MPa | ≥20MPa | ≥25% |

| 3003 | O/F/H111/H112 | ≥75MPa | ≥20MPa | ≥25% |

Application:

Beside increased global performances, an all-aluminum brazing tube heat exchanger using our aluminum condenser tube extrusion will also present better corrosion resistance. The aluminum tube extrusions are primarily used for the following applications:

Condensers

Evaporators

Oil coolers

Radiators

Heater cores

Related Keywords