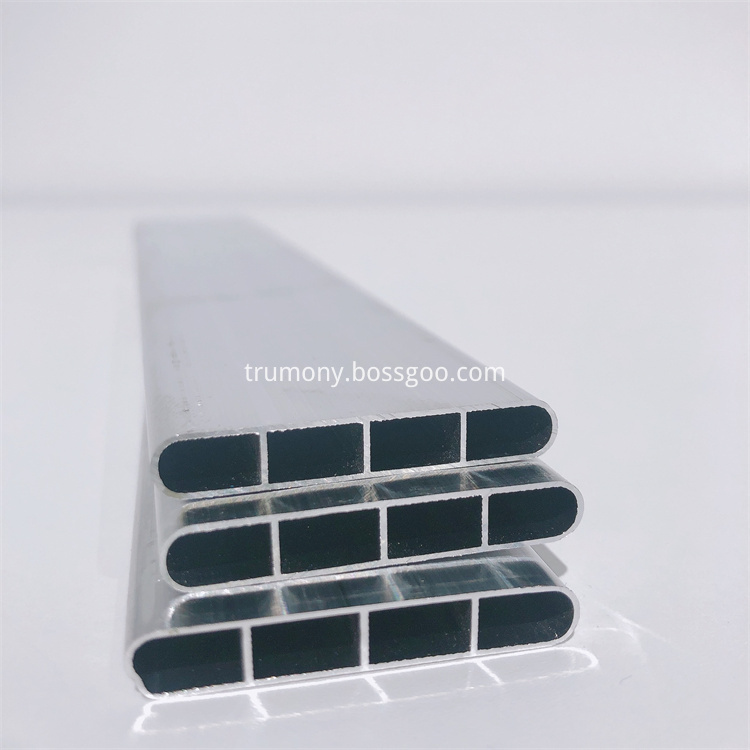

Aluminum Rectangular Microchannel Tube For Heat Exchanger

- Min. Order:

- 1 Ton

- Min. Order:

- 1 Ton

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Ningbo, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000tons/year |

| Supply Ability: | 10000tons/year |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | ISO9001,ISO14000 |

| HS Code: | 7607 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Ningbo,Qingdao |

Aluminum Rectangular Microchannel Tube For Heat Exchanger

Product introduction:

The aluminum micro channel tube is our very competitive products , we have 3 production lines to do them. The aluminum tube are widely used for new energy car air conditioning , household air conditioning and more heat exchangers. Except the usage, the aluminum extrusion pipe is also popular applied for electric vehicle, sich as liquid cooling tube for EV, liquid cooling tube for power storage etc.

Specification of base tube:

|

Steel Alloy |

DC01 etc., |

|

Aluminum alloy |

1079 etc., |

|

Steel thickness |

1.5mm etc |

|

Aluminum thickness |

0.04-0.095mm |

|

Width |

219mm etc., |

|

Height |

19mm etc., |

|

Length |

9000-14500mmm |

|

Temper |

HO |

Other sizes is available according to customer's request

Material of Steel(DC01 standard):

| Content(%) | C | Si | Mn | P | S | Alta |

| Steel | ≤0.12 | ≤0.03 | ≤0.6 | ≤0.045 | ≤0.045 | ≥0.02 |

Material of Aluminum(clad material 1079):

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Bi | Zr | Ti | Al |

| Max. | 0.85 | 0.45 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | - | 0.05 | 0.03 | Rem |

| Min. | 0.75 | 0.36 | - | - | - | - | - | - | - | - | - |

Base tube Performance:DC01 clad with Special alloy 1079

| Steel tube size | Size Tolerance | Steel tube straightness | Torsion resistance | Kerf Skewness | Thickness of aluminum | |||

| width | thickness | length | ||||||

|

219mm*19mm*1.5* 10562/9562mm |

±0.25mm | ±0.04mm | ±3mm | 0.05mm Per Meter | 0.5°per Meter | ±1.5mm | 60-90μm | |

| Eddy current inspection | 100% tested | Pressure Test | 100% tested for 20 Sec.At 0.25Mpa | |||||

Applications:

Beside increased global performances, an all-aluminium brazed heat exchanger using MPE will also present better corrosion resistance. MPEs are primarily used for the following applications:

Condensers

Evaporators

Oil coolers

Radiators

Heater cores

Package: In coil or Straight with fixed length.

Surface Treatment : With Zinc spraying or without Zinc spraying.

Related Keywords