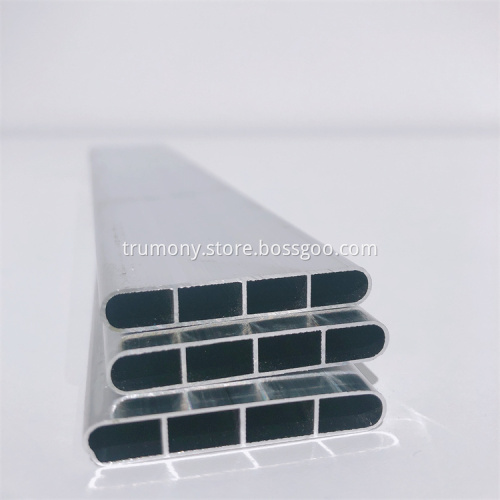

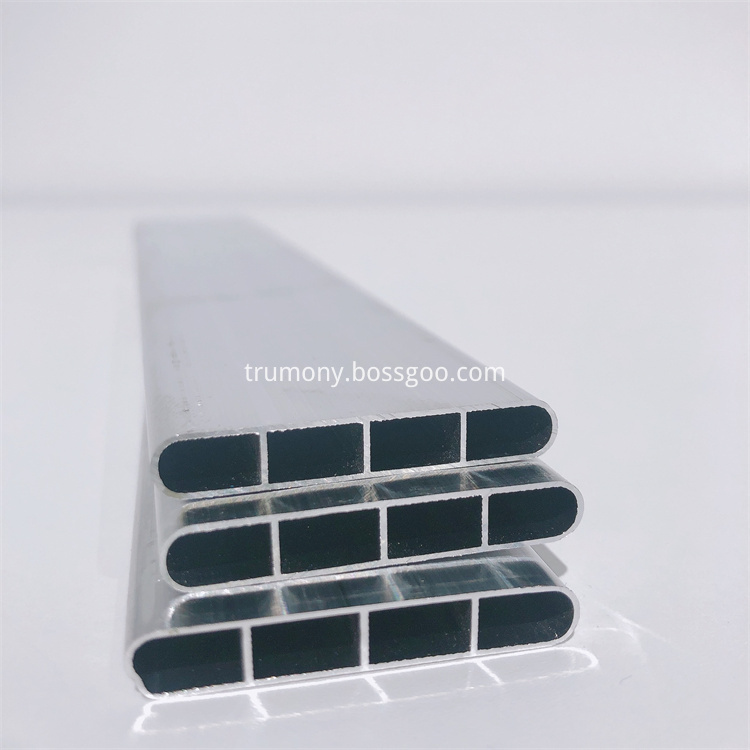

Aluminum Tube Microchannel Serpentine Heat Exchangers

- Min. Order:

- 1 Ton

- Min. Order:

- 1 Ton

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Ningbo, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000tons/year |

| Supply Ability: | 10000tons/year |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | ISO9001,ISO14000 |

| HS Code: | 7607 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Ningbo,Qingdao |

Aluminum Tube Microchannel Serpentine Heat Exchangers

Product introduction:

The Aluminum Micro channel tube are unique liquid cooling tube for EV developed with the highest manufacturing quality. Aluminum vapor chamber plate With their large internal surface area, aluminum brazing tube can achieve more efficient heat transfer and hence are ideal for use in highly effective heat exchangers.

The Aluminum tube is a highly refined quality product and is characterized by the following properties:

1. Low weight

2. Excellent conductor of heat and electricity

3. High corrosion resistance

4. High recycling value

5. High pressure resistance

6. High surface quality

Chemical composition

| No. | Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | V | Ti |

| 1 | 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | --- | ≤0.05 | ≤0.05 | ≤0.03 |

| 2 | 1100 | ≤0.95(Si+Fe) | 0.05-0.20 | ≤0.05 | --- | --- | ≤0.10 | --- | --- | |

| 3 | 3102 | ≤0.40 | ≤0.70 | ≤0.10 | 0.05-0.40 | --- | --- | ≤0.30 | --- | ≤0.10 |

| 4 | 3003 | ≤0.15 | ≤0.15 | ≤0.01 | 0.90-1.10 | ≤0.03 | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

Mechanical properties

| Alloy | Temper | Tensile Strength | Yield Strength | Elongation |

|

1050 |

O/F/H111/H112 | ≥65MPa | ≥20MPa | ≥25% |

| 1100 | O/F/H111/H112 | ≥75MPa | ≥20MPa | ≥25% |

| 3102 | O/F/H111/H112 | ≥75MPa | ≥20MPa | ≥25% |

| 3003 | O/F/H111/H112 | ≥75MPa | ≥20MPa | ≥25% |

Corrosion resistance : Salt spray test ≥750hours

Zn Coating standards : 6/8/10/13 +/-2g/m2

Flux Coating standards:10-15+/-2g/m2

The pressure resistance performance

| Automobile Condensers | Household Condensers | Evaporators |

| ≥9MPa | ≥13.5 MPa | ≥3.5 MPa |

Dimensions: The aluminum extrusion pipe are available in various sizes and alloys, ensuring the best properties for the purpose required.

| MPE | Width | 7-120mm |

| Height | 1-10mm | |

| Wall thickness | 0.2-0.5mm | |

| Other non-standard dimensions are available upon request. | ||

Applications:

Beside increased global performances, an all-aluminium brazed heat exchanger using MPE will also present better corrosion resistance. MPEs are primarily used for the following applications:

Condensers

Evaporators

Oil coolers

Radiators

Heater cores

Package: In coil or Straight with fixed length.

Surface Treatment : With Zinc spraying or without Zinc spraying.

Related Keywords