20L Bottle Water Filling Machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Shanghai Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Zhangjiagang City |

|---|---|

| Productivity: | 2000BPH |

| Supply Ability: | 20Sets/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

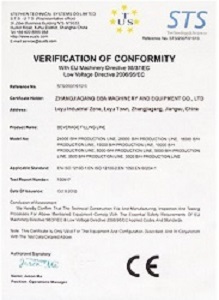

| Certificate: | ISO9001, CE |

| HS Code: | 8422309090 |

| Transportation: | Ocean |

| Port: | Shanghai Port |

20L Bottle Water Filling Machine

Washing Part

1.Lifting type high pressure washing sus304 nozzle,no washing dead corner, to make sure better washing effect and improve product quality.

2.Different washing water tank is equipped with electrical heating unit for customers special request. Heating water tank is made of high temperature material, and is equipped with liquid level measurement ,and temperature control detection control device and high temperature detergent rapid recovery unit,can significantly reduce heat loss,lower operating cost.

Filling Part

1.Filling speed is adjustable through variable frequency speed control.The liquid level is precisely controlled,no leakage,to ensure excellent filling quality.

2.All parts (including filling valves) that conact water are made of high quality stainless stell ss304 ,and no dead angle mirror-polished.

3,High quality electrical components ensure the running precision and stability of the machine.The materials give fully consideration to the requirements in food hygiene standards.

4.The filling valve is equipped with the device for automatic aligning with the bottle mouth to ensure precision at all times.

5.The elaborate pipeline design and the meticulous display of details represent extraordinary quality orientation.

Capping Part

1.Automaitc put cap on bottle mouth ,and use stainless steel cycle chain press cap continuous.

2.Automatic conveyor belt type cap uploading machine,ensure no back cap 100%.

3.Automatic cap on-line sterilizing device is optional according to customer's request, no secondary pollution cause by perpole hand.

Technical Parameter of Mineral Water Filling Machine

|

Model

|

QGF 150

|

QGF 300

|

QGF 450

|

QGF 600

|

QGF 900

|

QGF 1200

|

|

Bottle Data

|

Max Height:500mm Max Dia:280mm 55mm neck size

|

|||||

|

Rinser No

|

1

|

2

|

3

|

4

|

6

|

8

|

|

Capacity

|

150 b/h

|

300b/h

|

450b/h

|

600b/h

|

900b/h

|

1200b/h

|

|

Power (kw)

|

3.5

|

4.2

|

5.4

|

7.8

|

8.3

|

9.6

|

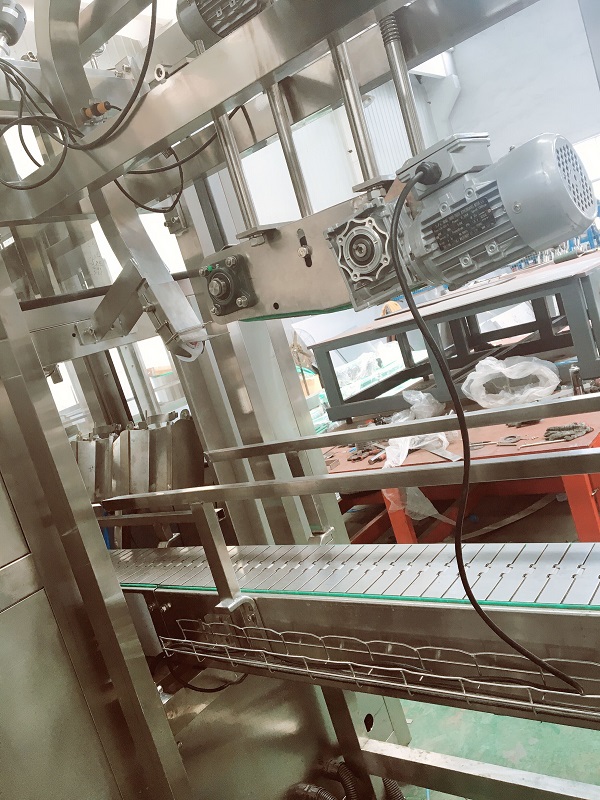

Factory Show

Packing and Shipping

Certificate

FAQ

Q: How about the spare parts?

A: We will send one year enough easy broken spare parts together with the machines, shipping together. During the warranty time, we will supply the spare parts with our cost including the delivery fees.

Q: How long time for installation?

A: According your machines order, we will send one or two engineers to your plant, it will take about 10 days to 25 days.

Q: How to install my machines when it arrives? How much the cost?

A: We will send our engineers to your factory to install the machines and train your staff how to operate the machines. Customer pay air tickets go and back accommodation and USD80/day/person.

Q: When can I get my machine after I paid?

A: Normally production time is around 30-60days, the exactly depend on what kind of machine you order. The shipping time is based on your destination port.

Q: What`s your guarantee or warranty of the quality if buy your machines?

A: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q: Are you a trading company or a manufacturer?

A:We are an original equipment manufacturer so that we can provide you high quality machines in reasonable price. Welcome to visit us.

Related Keywords