Automatic Extrusion Blow Moulding Machine for Oil Barrel

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

High capacity oil bottle injection blow molding machine Appliaction :

1. This type of oil filling machine is mainly suitable for all sorts of viscous and nonviscous, erosive liquid, such as plant oil chemical, liquid, daily chemical industry.

2. This machine integrates filling and capping in one machine.

3. This Liquid Filling Machine adopts low vacuum filling to ensure filling accurately without bubble of leakage.

4. Cap screwing device adopts assorted magnetic pieces-structure to avoid damaging the cap when screwing it on the bottle.

5. The machine will do filling and cap-screwing when there are bottles on the work position and it will not do filling and cap-screwing when there is not any bottle.

6. It needs to change the bottle conducting board when another kind of bottle is used in production.

7. The machine is easy to operate and to change for different kinds products.

8. It is applicable to the production of glass bottle and plastic bottles.

9. Using microcomputer PLC programmable control system of MITSUBISHI, air course system using AIRTAC Taiwan production, SUS304 material for filling valve Material of the filling valve can also be customized according to customer requirements to ensure quality of the filling machine.

10. It has applied German technique on photoelectric sensors.

11. There is a switch for step progressive type supply and continuous supply. It can be set optionally.

12. It can be installed with the CIP cleaning system according to customer requirement.

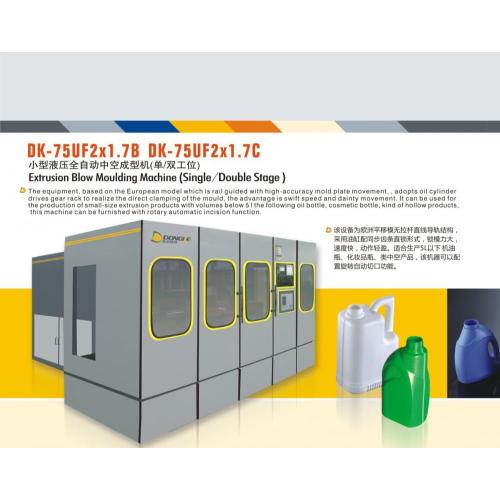

Lubricant Blow Molding Machine

We are specializing in large blow moulding machine from 1-10000L,1-3layers,1000L one-three layers blow moulding machine,2000L one-three layers blow moulding machine.This machine can produce civil barrel,IBC barrel,220L double L-ring barrel,plastic tray for forklift,underground storage-shaped hollow products.

With this machine you can make water tanks,pallets,roadblocks,and any other plastic products,the capacity from 0.5L-30L,upto 1-3layers.

Technical Specification/ 5-10L, 10-25L

|

Max.product Volume |

( L ) |

30 |

|

Screw Diameter |

(mm) |

90 |

|

Screw L / D ratio |

(L/D) |

25 |

|

Screw drive power |

(KW) |

37 |

|

Screw Heating capacity |

(KW) |

16 |

|

Extruder DC motor Power |

(KW) |

55 |

|

NO.of heating zone |

(zone) |

4 |

|

Output of HDPE |

(kg/h) |

150-200 |

|

Oil pump drive power |

(KW) |

18.5 |

|

Clamping force |

(KN) |

270 |

|

Platen distance |

(mm) |

200-660 |

|

Max.Size of Mold |

( WxH ) |

450x660 |

|

Capacity |

( L ) |

--- |

|

Max.Die diameter |

(mm) |

200 |

|

Die heat capacity(Single) |

(KW) |

12 |

|

NO.of heating zone |

(zone) |

4 |

|

Central distance of bi-die |

(mm) |

100-270 |

|

Max.Die diameter bi-head |

(mm) |

180 |

|

NO.of heating zone |

(zone) |

8 |

|

Heating capacity |

(KW) |

18 |

|

Cooling water pressure |

(Mpa) |

0.4 |

|

Water consumption |

(L/min) |

80 |

|

Total Power |

(KW) |

65 |

|

Size of machine |

(LxWxH)m |

5x3.5x2.8 |

|

Weight of machine |

(TON) |

12 |

|

Dry cycle |

(pc/h) |

600

|

Related Keywords