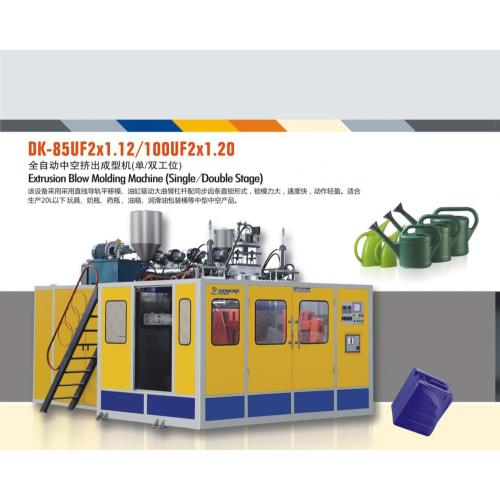

Bottle lubricant Oil Barrel Blow Molding Machine

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

Suitable for

(1)Suitable for producing different kinds of car urea box, tool box, automotive seat, auto air duct, auto flow board, bumper and Car spoilers.

(2)Suitable for producing different Car shaped pipe fittings products, like the automotive oil filler pipe, air ducts pipe and others.

(3)Suitable for producing different kinds of pallet.

(4)Suitable for producing 500-100L big size Chemical revolving barrel.

(5)producing 15-100L different size jerrycan, open-top barrels and other chemical packaging produts.

(6)producing 15-30L different size Chemical packing jerrycan.

(7)Suitable for producing 1-5L different size of gear oil bottle, lubrication oil bottle, cooling water tank etc.

Automatic Bottle Blowing Machine is suitable for producing PP/PE/PU/PC/PVC/PETG/HDPE/LDPE/ABS/..... plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc. Beverage bottle, cosmetic bottle, medicine bottle, jar etc.

Lubricant Blow Molding Machine

We are specializing in large blow moulding machine from 1-10000L,1-3layers,1000L one-three layersBlow Moulding Machine Accessories,2000L one-three layers Pet Blow Moulding Machine.This machine can produce civil barrel,IBC barrel,220L double L-ring barrel,plastic tray for forklift,underground storage-shaped hollow products.

With this machine you can make water tanks,pallets,roadblocks,and any other plastic products,the capacity from 0.5L-30L,upto 1-3layers.

Technical Specification/ 5-10L, 10-25L

|

Max.product Volume |

( L ) |

30 |

|

Screw Diameter |

(mm) |

90 |

|

Screw L / D ratio |

(L/D) |

25 |

|

Screw drive power |

(KW) |

37 |

|

Screw Heating capacity |

(KW) |

16 |

|

Extruder DC motor Power |

(KW) |

55 |

|

NO.of heating zone |

(zone) |

4 |

|

Output of HDPE |

(kg/h) |

150-200 |

|

Oil pump drive power |

(KW) |

18.5 |

|

Clamping force |

(KN) |

270 |

|

Platen distance |

(mm) |

200-660 |

|

Max.Size of Mold |

( WxH ) |

450x660 |

|

Capacity |

( L ) |

--- |

|

Max.Die diameter |

(mm) |

200 |

|

Die heat capacity(Single) |

(KW) |

12 |

|

NO.of heating zone |

(zone) |

4 |

|

Central distance of bi-die |

(mm) |

100-270 |

|

Max.Die diameter bi-head |

(mm) |

180 |

|

NO.of heating zone |

(zone) |

8 |

|

Heating capacity |

(KW) |

18 |

|

Cooling water pressure |

(Mpa) |

0.4 |

|

Water consumption |

(L/min) |

80 |

|

Total Power |

(KW) |

65 |

|

Size of machine |

(LxWxH)m |

5x3.5x2.8 |

|

Weight of machine |

(TON) |

12 |

|

Dry cycle |

(pc/h) |

600

|

Related Keywords