Automatic Plastic Lubricant Oil Barrel Blow Molding Machine

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

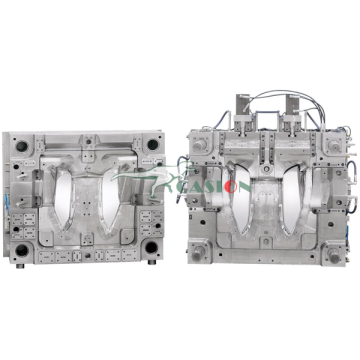

This is Lubricant oil bottle 1L 3L 4L 5L PE blow molding machine / HDPE blow molding machine, A wide variety of materials can be used for the machine, which are suitable for producing 100ml to 4L PE canster , jerrycan, gallon ,water kettle. The clamping system is a high-precision double-station linear guide, extrusion system using a hard gear reducer and inverter. The die head system adopts central-incoming extrusion die made of special steel, imported hydraulic valve and seal parts with proportional control valve.The control system consists of PLC and Human-machine interface imported from Japan, and automatic temperature control module and imported electrical parts.

Lubricant Blow Molding Machine

We are specializing in large blow moulding machine from 1-10000L,1-3layers,1000L one-three layers blow moulding machine,2000L one-three layers Water Tank Blow Moulding Machine.This machine can produce civil barrel,IBC barrel,220L double L-ring barrel,plastic tray for forklift,underground storage-shaped hollow products.

With this machine you can make water tanks,pallets,roadblocks,and any other plastic products,the capacity from 0.5L-30L,upto 1-3layers.

The machine is suitable to produce single layer, three layer and viewline bottles, it is good to produce plastic material such as HDPE/PP/LDPE.

This machine is controlled by PLC system, the working speed could be adjusted by operators over touch screen.

Technical Specification/ 5-10L, 10-25L

|

Max.product Volume |

( L ) |

30 |

|

Screw Diameter |

(mm) |

90 |

|

Screw L / D ratio |

(L/D) |

25 |

|

Screw drive power |

(KW) |

37 |

|

Screw Heating capacity |

(KW) |

16 |

|

Extruder DC motor Power |

(KW) |

55 |

|

NO.of heating zone |

(zone) |

4 |

|

Output of HDPE |

(kg/h) |

150-200 |

|

Oil pump drive power |

(KW) |

18.5 |

|

Clamping force |

(KN) |

270 |

|

Platen distance |

(mm) |

200-660 |

|

Max.Size of Mold |

( WxH ) |

450x660 |

|

Capacity |

( L ) |

--- |

|

Max.Die diameter |

(mm) |

200 |

|

Die heat capacity(Single) |

(KW) |

12 |

|

NO.of heating zone |

(zone) |

4 |

|

Central distance of bi-die |

(mm) |

100-270 |

|

Max.Die diameter bi-head |

(mm) |

180 |

|

NO.of heating zone |

(zone) |

8 |

|

Heating capacity |

(KW) |

18 |

|

Cooling water pressure |

(Mpa) |

0.4 |

|

Water consumption |

(L/min) |

80 |

|

Total Power |

(KW) |

65 |

|

Size of machine |

(LxWxH)m |

5x3.5x2.8 |

|

Weight of machine |

(TON) |

12 |

|

Dry cycle |

(pc/h) |

600

|

Related Keywords