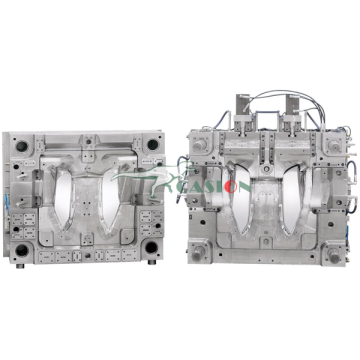

Plastic Water Horse Fence Blow Molding Machine

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

1). Stable performance with advanced PLC.

2). Automatic preform conveyer to save human cost.

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5). High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Introduce the air cylinder to avoid contamination and noise.

7). Satisfaction with different atmospheric pressure for Ibc Blowing Machine and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

8). Strong clamping force with high pressure and double crank links to lock the mould.

9). Two ways of operating: automatic and manual.

10). Safe\reliable and unique design of the position of valve to make the pneumatic diagram in the machine easier to understand.

11). Low cost\high efficiency\easy operation and maintenance etc, profited from the fully automatic technological process.

12). Ideal cooling system make the finished bottles without any flaws.

13). Easy for you to install\test and start up.

14). Low rejection rate: less than 0.2 percent

Large Multi Layer bucket Blow Molding Machine

We are specializing in large blow moulding machine from 200-5000L,1-3layers,1000L one-three layers blow moulding machine,2000L one-three layers Blow Moulding Machine.This machine can produce civil barrel,IBC barrel,220L double L-ring barrel,plastic tray for forklift,underground storage-shaped hollow products.

With this machine you can make water tanks,pallets,roadblocks,and any other plastic products,the capacity from 250L-3000L,upto 2-4layers.

2Layers Extrusion Blow Moulding Machine

|

Specification |

|

1000L |

2000L |

3000L |

5000L |

|

Max container capacity |

L |

1000 |

2000 |

3000 |

5000 |

|

Machine Weight |

T |

32 |

43 |

49 |

60 |

|

Machine Dimension(L*W*H) |

M |

7*6.5*5 |

8*7*6.5 |

9*8*7.5 |

11*7*7.5 |

|

Total Power |

Kw |

196 |

277 |

327 |

482 |

|

Average Power Consumption |

Kw |

127 |

180 |

212 |

313 |

|

Die Head |

|

|

|

|

|

|

Accumulator Volume |

KG |

35 |

60 |

80 |

150 |

|

Number of Heating Zone |

Zone |

11 |

10 |

12 |

12 |

|

Power of Die Heating |

Kw |

55 |

80 |

100 |

120 |

|

Max. Die-pin Diameter |

mm |

450 |

600 |

800 |

820 |

|

Extruder Unit |

|

|

|

|

|

|

Screw Diameter |

mm |

100/100 |

120/120 |

130/130 |

150/150 |

|

Screw L/D Ratio |

L/D |

25/1 |

25/1 |

25/1 |

25/1 |

|

Number of Heating Zone |

Zone |

8 |

10 |

10 |

12 |

|

Heating Power |

Kw |

44 |

55 |

55 |

72 |

|

Max. Melting Capacity |

KG/Hr. |

370 |

470 |

540 |

670 |

|

Extruder Motor Power |

Kw |

30/30 |

45/45 |

55/55 |

110/110 |

|

Clamping Unit |

|

|

|

|

|

|

Max. Mould Size(W*H) |

mm |

1200*1500 |

1500*2000 |

1700*2200 |

2000*2400 |

|

Distance Between Platen |

mm |

800~2400 |

1000~3000 |

1200~3400 |

1300~3600 |

|

Platen Size(W*H) |

mm |

1500*1500 |

1800*2000 |

2000*2200 |

2200*2400 |

|

Clamping Force |

KN |

800 |

1200 |

1200 |

1800 |

|

Hydraulic System |

|

|

|

|

|

|

Main Oil Pump Power |

Kw |

30 |

45 |

55 |

55 |

|

Servo Oil Pump Power |

Kw |

7.5 |

7.5 |

7.5 |

15 |

|

Thickness Controll System |

Point |

100 |

100 |

100 |

100 |

3Layers blow moulding machine

|

Specification |

|

1000L |

2000L |

3000L |

5000L |

|

Max container capacity |

L |

1000 |

2000 |

3000 |

5000 |

|

Machine Weight |

T |

38 |

48 |

59 |

75 |

|

Machine Dimension(L*W*H) |

M |

7*7.5*5.5 |

8*8*6.5 |

9*7*7.5 |

10*8*7.5 |

|

Total Power |

Kw |

287 |

336 |

417 |

526 |

|

Average Power Consumption |

Kw |

186 |

218 |

271 |

341 |

|

Die Head |

|

|

|

|

|

|

Accumulator Volume |

KG |

35 |

60 |

80 |

150 |

|

Number of Heating Zone |

Zone |

11 |

11 |

13 |

16 |

|

Power of Die Heating |

Kw |

88 |

100 |

130 |

160 |

|

Max. Die-pin Diameter |

mm |

450 |

600 |

800 |

820 |

|

Extruder Unit |

|

|

|

|

|

|

Screw Diameter |

mm |

100/110/100 |

110/120/110 |

120/130/120 |

130/138/130 |

|

Screw L/D Ratio |

L/D |

25/1 |

25/1 |

25/1 |

25/1 |

|

Number of Heating Zone |

Zone |

13 |

13 |

15 |

16 |

|

Heating Power |

Kw |

65 |

65 |

80 |

96 |

|

Max. Melting Capacity |

KG/Hr. |

370 |

470 |

540 |

600 |

|

Extruder Motor Power |

Kw |

30/30/37 |

37/37/45 |

45/45/45 |

55/55/90 |

|

Clamping Unit |

|

|

|

|

|

|

Max. Mould Size(W*H) |

mm |

1200*1500 |

1500*2000 |

1700*2200 |

2000*2400 |

|

Distance Between Platen |

mm |

800~2400 |

1000~3000 |

1200~3400 |

1300~3600 |

|

Platen Size(W*H) |

mm |

1500*1500 |

1800*2000 |

2000*2200 |

2200*2400 |

|

Clamping Force |

KN |

800 |

1200 |

1200 |

1800 |

|

Hydraulic System |

|

|

|

|

|

|

Main Oil Pump Power |

Kw |

30 |

45 |

55 |

55 |

|

Servo Oil Pump Power |

Kw |

7.5 |

7.5 |

7.5 |

15 |

|

Thickness Controll System |

Point |

100 |

100 |

100 |

100 |

4Layers blow moulding machine

|

Specification |

|

1000L |

2000L |

3000L |

5000L |

|

Max container capacity |

L |

1000 |

2000 |

3000 |

5000 |

|

Machine Weight |

T |

44 |

60 |

70 |

85 |

|

Machine Dimension(L*W*H) |

M |

9*7.5*5.5 |

10*8*6.5 |

11*8*7.5 |

12*8*8 |

|

Total Power |

Kw |

351 |

441 |

532 |

630 |

|

Average Power Consumption |

Kw |

228 |

286 |

346 |

409 |

|

Die Head |

|

|

|

|

|

|

Accumulator Volume |

KG |

35 |

60 |

80 |

150 |

|

Number of Heating Zone |

Zone |

12 |

14 |

16 |

18 |

|

Power of Die Heating |

Kw |

12 |

140 |

160 |

180 |

|

Max. Die-pin Diameter |

mm |

450 |

600 |

800 |

850 |

|

Extruder Unit |

|

|

|

|

|

|

Screw Diameter |

mm |

90/100/100/90 |

100/110/110/100 |

110/120/120/110 |

120/130/130/120 |

|

Screw L/D Ratio |

L/D |

25/1 |

25/1 |

25/1 |

25/1 |

|

Number of Heating Zone |

Zone |

18 |

18 |

20 |

20 |

|

Heating Power |

Kw |

90 |

99 |

110 |

120 |

|

Max. Melting Capacity |

KG/Hr. |

370 |

470 |

540 |

670 |

|

Extruder Motor Power |

Kw |

22/22/30/30 |

30/30/45/45 |

45/45/55/55 |

55/55/75/75 |

|

Clamping Unit |

|

|

|

|

|

|

Max. Mould Size(W*H) |

mm |

1200*1500 |

1500*2000 |

1700*2200 |

2000*2400 |

|

Distance Between Platen |

mm |

800~2400 |

1000~3000 |

1200~3400 |

1300~3600 |

|

Platen Size(W*H) |

mm |

1500*1500 |

1800*2000 |

2000*2200 |

2200*2400 |

|

Clamping Force |

KN |

800 |

1200 |

1200 |

1800 |

|

Hydraulic System |

|

|

|

|

|

|

Main Oil Pump Power |

Kw |

30 |

45 |

55 |

55 |

|

Servo Oil Pump Power |

Kw |

7.5 |

7.5 |

7.5 |

15 |

|

Thickness Controll System |

Point |

100 |

100 |

100 |

100 |

Related Keywords