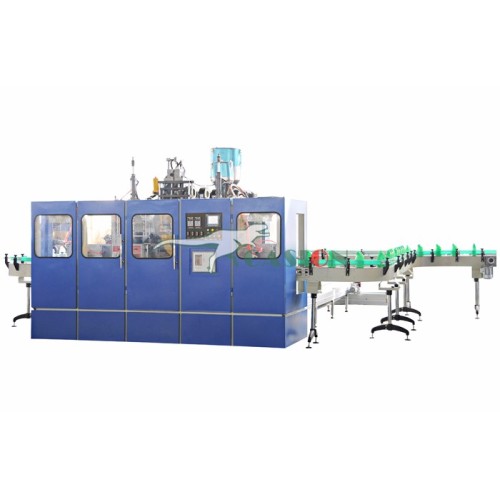

PET PE Plastic Bottle Blow Molding Machine

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean, Land

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

Product Description

Product Description

Adopt imported linear guide rail, double station, quick moving die, good stability.

Hydraulic system: optimize hydraulic circuit design, power saving, quick movement and stability. The hydraulic component is easy to install and maintain, and can be assembled and disassembled.

Electronic control system: the whole machine adopts MITSUBISHI PLC plus machine interface control, with automatic alarm device, reliable work, high degree of automation, can store 40 sets of mold materials.

KHX-KS65UF2x4-500ml

Technical Data for Blow Molding KHX-KS65UF2x4-1000ml1. General Issues

Machine operating manual including Hydraulic, Pneumatic, Assembly drawing, Cooling water.

Max. volume of product: single cavity 500mL

Total weight 12 ton 3.5-4.5bars

Max. output 600pcs/h (250mL product net weight 30-50g,Sufficient cooling water temperature at

8℃ with an intake pressure of between 3.5 to 4.5 bars, with a Min. difference between intake and outlet of 3 bars. )

2. Clamping Unit

Principle: bi-direction synchronous clamping device with double axis.

Linear roller guidance horizontal.

Clamping force: 150KN

Mold platens H x W 400 x 500 mm

Distance between the p;atens: 150-550mm

Clamping unit stroke: 300mm

3. Die Head

Type of die head: Double lays head of accumulator.

Max mouth diameter: 8- 30MM

Max. Storage volume:

Type of temperature sensors: K

Heater power: 15KW

100 point WPS systerm controller (B&R) or MOOG 100 poing

4. Extruder System

Extruder should be adequate to work with HDPE

Screw diameter: 65-75/30D

Nitride treatment barrel and screw.

Plasticizing efficiency: 80-100 kg/h (HDPE)

Feeding zone grooved with cooling water

Cast-aluminium heater, adopt European mode of connection

Type of temperature sensors:

DC motor drive: 15KW

Cooling by 5 cooling fans.

Raw material hopper with a window.

5.Blow System

Blow system mounted on linear guide under the mold.

Height adjustment mechainsm 150 mm

Blow pin up/down stroke: 150 mm , controlled by hydraulic cylinder

Parison closed

Mechanical adjustment for left and right

6. Take out system

Take out stroke 400 mm

Adopt lear guide and synchronous belt transmission of motor to advance and retreat

Gripper with the function: auto cooling water

7. Hydraulic System

Hydraulic working pressure 100 -150 bar

Hydraulic system servo pump : 80 L/min

Hydraulic valves:Yuken brand

Oil Temperature sensor showing the screen

Motor power: 7.5-15 KW

Servo system

Servo valve: (REXROTH--From Germany)

Servo oil source:4KW

Piston pump:YUken (YUKEN--From Japan)

Threads of hydraulic block use of screw joint GE(ISO 1179)

8. Pneumatic System

Pneumatic cylinders AIRTEC

Pneumatic valves AIRTEC

Max. pressure of all components: 10 bar

Max. pressure of gauge: 6-8bar

9.Control System

Control System:Moog

Servo WDS control system:

Moog 100point.

Full color 12.4"

Full color 12.4" screen.

Recipe and machine data storage on memory stick (CF)

Emergency stop push buttons (rotationally release) without key

All electric components needs to be for power supply 220V/380V, 50Hz, controller DC24V,

Total rated power: 76 KW

Average energy consumption: 22-30 KW

Main components (Air switch, Contactor) :Schneider intermediate relay: Schneider

Invertot of extuder motor: PARK

Linear transducer: Gefran

Proximity switch: Schneider

Cooling water

All pipes for cooling water made of rubber material.

Separate cooling water circuit for Mold, Blow pin, Extruder feeding zone, Oil cooling.

Water consumptions: 10m3/h

11.Machine frame

Clamping unit should be forward: 600 mm, for Lubricant Blow Molding Machine changing

Aluminum profiles for safety doors, with plastic window.

Machine color: according requirement of customer

Overall dimensions of machine LxWxH: 2.8 x 3.2x 3.0 m

Related Keywords

Related Keywords