Plastic Bottle Extrusion Blow Mold

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

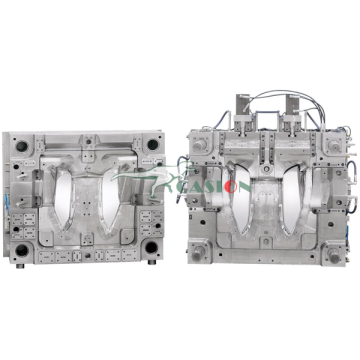

0.5ml~1000ml Bottle Blowing Mould

●Technical Specifications:

|

Item |

Description |

|

Mould Type |

0.5ml~1000ml Bottle Blowing Mould |

|

Cavity No.: |

Single or Multi |

|

Scope of Application |

Food Bottles,Beverage bottles,Chemical bottle,Seasoning Bottle,Pesticide Bottle |

|

Mould Material |

S45C,S50C,P20,3Cr13,718H,NAK80/magnalium |

|

Products Material |

PP,PE |

|

Specification |

According to customer's requirements. |

|

Design & program softwares |

CAD/CAM/CAE,UG,PRO/E,Cimatron,Powermill,Solidworks,Catia,etc. |

|

Package |

wooden case |

|

Delivery time |

30~35 days |

|

Payment Terms: |

T/T or L/C |

|

After-sales Services: |

Experienced engineers will provide all-round technical solutions to any problems occurred in customers mould operation. |

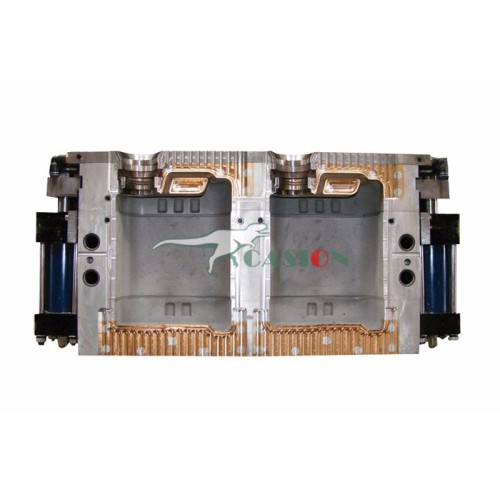

●Technical Specifications:

|

Item |

Description |

|

Mould Type |

2~5 gallon Barrel Mould |

|

Cavity No.: |

Single |

|

Mould Material |

S45C,S50C,,P20,3Cr13,718H,NAK80/magnalium |

|

Products Material |

PE,PC,PET |

|

Specification |

According to customer's requirements. |

|

Design & program softwares |

CAD/CAM/CAE,UG,PRO/E,Cimatron,Powermill,Solidworks,Catia,etc. |

|

Package |

wooden case |

|

Delivery time |

30~35 days |

|

Payment Terms: |

T/T or L/C |

|

After-sales Services: |

Experienced engineers will provide all-round technical solutions to any problems occurred in customers mould operation. |

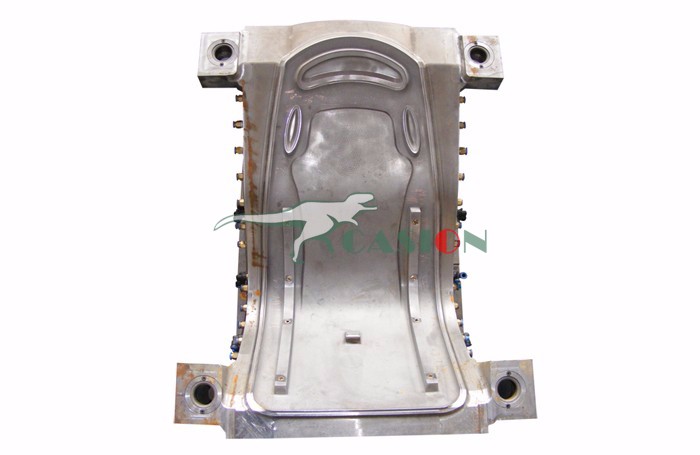

● Technical Specifications:

|

Item |

Description |

|

Mould Type |

Water Purifier Inner-container Mould |

|

Water Purifier Capacity |

5L~1000L |

|

Cavity No.: |

Single |

|

Mould Material |

S45C,S50C,,P20,3Cr13,718H,NAK80/magnalium/Cast Aluminium |

|

Products Material |

PE,PP |

|

Specification |

According to customer's requirements. |

|

Design & program softwares |

CAD/CAM/CAE,UG,PRO/E,Cimatron,Powermill,Solidworks,Catia,etc. |

|

Package |

wooden case |

|

Delivery time |

30~35 days |

|

Payment Terms: |

T/T or L/C |

|

After-sales Services: |

Experienced engineers will provide all-round technical solutions to any problems occurred in customers mould operation. |

● Technical Specifications:

|

Item |

Description |

|

Mould Type |

Toy Mould |

|

Cavity No.: |

Single or Multi |

|

Mould Material |

S45C,S50C,,P20,3Cr13,718H,NAK80/magnalium |

|

Products Material |

PE,PC |

|

Specification |

According to customer's requirements. |

|

Design & program softwares |

CAD/CAM/CAE,UG,PRO/E,Cimatron,Powermill,Solidworks,Catia,etc. |

|

Package |

wooden case |

|

Delivery time |

30~35 days |

|

Payment Terms: |

T/T or L/C |

|

After-sales Services: |

Experienced engineers will provide all-round technical solutions to any problems occurred in customers mould operation. |

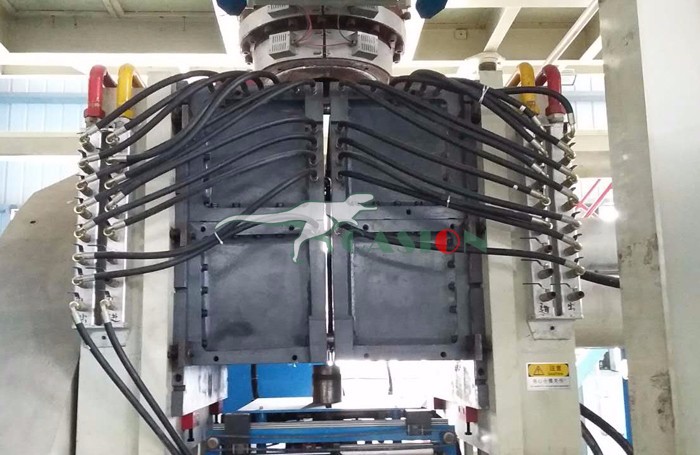

●Technical Specifications:

|

Item |

Description |

|

Mould Type |

1000L~5000L IBC TANK Mould |

|

Cavity No.: |

Single |

|

Mould Material |

Cast Aluminium etc..(For Reference) |

|

Products Material |

HDPE |

|

Specification |

According to customer's requirements. |

|

Design & program softwares |

CAD/CAM/CAE,UG,PRO/E,Cimatron,Powermill,Solidworks,Catia,etc. |

|

Machines |

|

|

Package |

wooden case |

|

Delivery time |

30~35 days |

|

Payment Terms: |

T/T or L/C |

|

After-sales Services: |

Experienced engineers will provide all-round technical solutions to any problems occurred in customers mould operation. |

Plastic Mould description:

1)Material: HDPE

2)Mould material: Steel1045,P20,Cr12,DC53,H13 etc

3)Surface Finish: chrome plating,silk-printing,texture,color painting etc

4)Injection machine production ability: from 0.1g to 6000g

5)The product in the pictures are our customers' OEM products,it's only for reference

As a professional manufacturer, our range products are covered from sanitary ware,household appliances, medical appliance, electronic, automobile, and so on.

About our Quick Mold Change System department, we have professional designers and experienced technicians. We are using 2D or 3D software to design drawings for our customers. With advanced molding technology, wire cutting machines, and CNC manufacturing centers,we can develop high quality moulds. The capacity of our mold department can produce 400-500 Mold System per year up to the tool sizes.

About our plastic injection department, we have 15 precision injection machines, range from 50T to 380T, and able to deal with general plastic, engineering plastic and the special material according to our customer`s requests.

Related Keywords