Roadblock Series Blow Mold

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

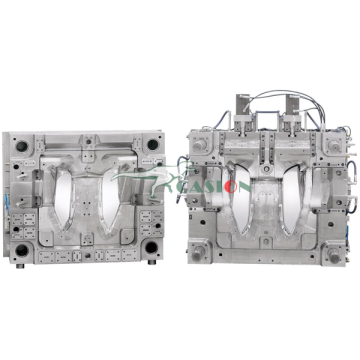

Roadblock series blow mold

CASION MOULD provides perfect solution for all kinds of plastic container mould development and production, the current products mainly include injection mould and blow mould, could meet the customization needs from different users.

For Blow Mould:

①We choose good material for cooling and improve cooling structure, always focus on the cooling balance and its pertinence,

②According to the bottle size, shape and performance, we will distinguish different cutting edges, continue to optimize the auto-deflashing system.

③CASION MOULDS are designed compactly, we insist on humanity, facilitate customers to dismounting and maintain moulds easily.

Plastic mould description:

1)Blow mold material:high quality steel,The material at both ends is high hardness die steel S316, and the intermediate material is aluminum alloy.

2)Structure: single cavity blow mold

3)Surface Finish: chrome plating,silk-printing,texture,color painting etc

4)Injection machine production ability: from 0.1g to 6000g

5)The product in the pictures are our customers' OEM products,it's only for reference

As a professional manufacturer, our range products are covered from sanitary ware,household appliances, medical appliance, electronic, automobile, and so on.

About our Quick Mold Change System department, we have professional designers and experienced technicians. We are using 2D or 3D software to design drawings for our customers. With advanced molding technology, wire cutting machines, and CNC manufacturing centers,we can develop high quality molds. The capacity of our mold department can produce 400-500 Mold System per year up to the tool sizes.

About our plastic injection department, we have 15 precision injection machines, range from 50T to 380T, and able to deal with general plastic, engineering plastic and the special material according to our customer`s requests

Related Keywords