Plastic Chair Making Machine/Blow Moulding Machine

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

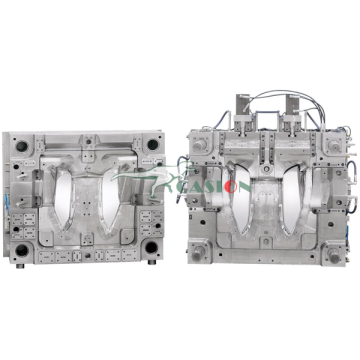

Automatic Blow Molding Machine

Brand : KHX-MACHINE

small bottle automatic pet blow molding machine

A,Adopted advanced MCU control system, stable performance

B,Conveyor automatic feeding preform

C,Adopt infrared tubes heating, strong penetrating power, bottle preform rotation heating, circle revolution, heated evenly, fast and reliable.

D,The tubes of heating zone, reflex plate width and height can be adjusted to suit different structure of preform heating, and has automatic device of vent temperature, to ensure that constant temperature.

E,Each mechanical movement had safety self-lock device, when a process malfunction, the program will automatically switch to safe state

F,Each movement driven by cylinder, do not use oil pump, no pollution, low noise etc advantage,

G,The pneumatic system divide into action and blowing two parts, to satisfy the bottle blowing and action different pressure demand

KHX-260-120

Technical Data for Injection Blow Molding Machine KHX-260-120

1. General Issues

Machineoperating manual including Hydraulic, Pneumatic, Assembly drawing, Coolingwater.

Max.volume of product: single cavity 260L Total weight 35 ton 3.5-4.5bars

Max. output 20pcs/h (220L product net weight 10.5Kg,Sufficientcooling water temperature at

8℃ with an intake pressure of between3.5 to 4.5 bars, with a Min. difference between intake and outlet of 3 bars. )

2. Clamping Unit

Principle: bi-direction synchronous clampingdevice with double axis.

Linearroller guidance horizontal.

Clampingforce: 750KN

Moldplatens H x W 1500 x 1000 mm

Distancebetween the p;atens: 750-1750mm

Clampingunit stroke: 1000mm

3. Die Head

Typeof die head: Double lays head of accumulator.

Max mouth diameter: 180-400MM

Max.Storage volume: 20L

Typeof temperature sensors: K

Heaterpower: 52KW

100point WPS systerm controller (B&R)

4. Extruder System

Extrudershould be adequate to work with HDPE

Screwdiameter: 120/30D

Nitridetreatment barrel and screw.

Plasticizingefficiency: 400 kg/h (HDPE)

Feedingzone grooved with cooling water

Cast-aluminium heater, adopt European mode ofconnection

Typeof temperature sensors:

DC motor drive: 132KW

Coolingby 5 cooling fans.

Raw material hopper with awindow.

5.BlowSystem

Blowsystem mounted on linear guide under the mold.

Heightadjustment mechainsm 250 mm

Blow pin up/down stroke: 150 mm , controlledby hydraulic cylinder

Parison closed

Mechanical adjustment for left and right

6. Take out system

Takeout stroke 1600 mm

Adopt lear guide and synchronous belttransmission of motor to advance and retreat

Gripper with the function: auto coolingwater

7. Hydraulic System

Hydraulic working pressure 100 -150 bar

Hydraulicsystem servo pump : 220 L/min

Hydraulicvalves:Yuken brand

Oil Temperature sensor showing the screen

Motor power: 22KW

Servosystem

Servovalve: (REXROTH--FromGermany)

Servooil source:4KW

Pistonpump:YUken (YUKEN--From Japan)

Threads ofhydraulic block use of screw joint GE(ISO 1179)

8. Pneumatic System

Pneumaticcylinders AIRTEC

Pneumatic valves AIRTEC

Max. pressure of all components: 10 bar

Max. pressure of gauge: 6-8bar

9.Control System

ControlSystem:B&R

B&R100point.

ServoWDS control system: B&R100point.

Full color 12.4"

Fullcolor 12.4" screen.

Recipeand machine data storage on memory stick (CF)

Emergencystop push buttons (rotationally release) without key

Allelectric components needs to be for power supply 220V/380V, 50Hz, controllerDC24V,

Total rated power: 276 KW

Average energy consumption: 110 KW

Main components(Air switch, Contactor) :Schneider intermediate relay: Schneider

Invertot of extuder motor: PARK

Linear transducer: Gefran

Proximity switch:Schneider

Cooling water

Allpipes for cooling water made of rubber material.

Separatecooling water circuit for Mold, Blow pin, Extruder feeding zone, Oil cooling.

Waterconsumptions: 20m3/h

11.Machine frame

Clamping unit should beforward: 600 mm, for mold changing

Aluminum profiles for safety doors, with plastic window.

Machinecolor: according requirement of customer

Overall dimensions ofmachine LxWxH: 5.5 x 6.5 x 3.6 m

Advantages of Rotary Automatic Stretch-Blow Molding Machines

High productivity: 1700pcs/cavity/hour

High eligible rate: above 99.6%

Adopting SIMENS electric controlling system; with high precision and fast speed

Stable function:

Blowing system adopts Germany valve and cylinder, which has stable and accurate stretching speed and good product consistency

Heating system adopts PHILIPS original infrared lamps, which is good in thermal properties and high in durability.

Mold fixing structure assures fast mold fixing speed and fast mold changing speed

Automatic plastic loader and automatic recovery device.

Related Keywords