Industrial Chiller Air Cooled Water Chiller

- Payment Type:

- T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Transportation: | Ocean,Land |

Features

1.Working without water-cooling tower,it provides easier installation and higher mobility.Independent cooling system. It's a wonderful choice for places lacking of water or those water-cooling tower is not applicable.

2.Low noise fan motor provides excellent cooling and condensation effects.The throttle unit is stable,with high-grade anti-rust treatment.

3.Compressor---Equipped with a world famous brand Copeland scroll compressor.The compressor operates smoothly and quietly at high EER value.

4.Thermal expansion valve(TXV)---Normally, our standard type is Danfoss brand.

5.Condenser---SUNCHI air-cooled scroll chiller adopts fin type with copper coil.

6.Evaporator---Normally,there are 3 types for the evaporator,water tank copper coil,shell and tubes,stainless steel heat exchanger.

Air Cooled Water Chiller

·

·

·

Air Cooled Water Chiller

Brand : KHX-MACHINE

Product origin : SUZHOU CHINA

Design advantages:

1. Compact structure,smooth operation: Condenser and evaporator units adopt efficient heat transfer tubes.We select imported efficient hermetic scroll compressor as our most important parts in our chiller,which has a compact structure,small size,light weight,easy installation and many other advantages.Hermetic scroll compressor has lessoperation parts.We use flexible compressor which has high energy efficiency,low noise,low operating costs,automatically unload pressure without frication and high reliability advantages.The compressor is continuous no-pulse compressor; hence the unit has a stable performance,low noise,small vibraion,smooth running characteristics,which cansave 20-30% power energy than the reciprocating compressor.

2.Complete energy control system: The units automatically start and stop according to load changes,more energy saving.When running,the computer control system will

be based on the user' s thermal load changes to alter the energy output of the unit.By monitoring difference between the user' s setting and the actual load,the microcomputer judges quickly and determines the energy output quickly.Among the multi system,the unit chooses the best way to optimize the output cooling work with less electric powerconsumption,and not only reflects the excellent performance at full load,but also has a high operating efficiency even at partial load.

3.Simple and intuitive: The unit uses microcomputer program controller (Chinese display /digital display).Following the prompts on the screen or panel,select the menu directly by finger and touch the button to start the unit.Panel can display operating status of the unit at any time.Ways to display as text form parameters can be saw at a glance,and even laypeople can operate it easily.Precision temp control is ±1℃,special demanded temp control ±0.1℃ also can be reached.

4.Microcomputer controller protection features :Compressor coil over current protection; pump over current protection; cold water flow switch protection; cold watertemperature too low protection ;over temperature protection; compressor overload protection; start and stop frequently protection; abnormal voltage protecton; high and lowvoltage protection and other protection.

5.Multiple protection,safe and reliable: In addition to the internal compressor protection module providing ultra under voltage,phase failure,overload protection andother protection functions of the unit,the pressure control system of the refrigeration system and other devices can also ensure it operate well.

6.Optimized configuration: High efficient refrigeration; easy to move; less noise making; meet environmentalfriendly requirements; Air cooled chiller can be equippedwithout a cooling tower.

7.Easy installation: Installation of all components,running tests,filling refrigerant and filling refrigeration oil of the unit has been finished before ex-factory.As long asusers connect the waterway and the circuit,it can be put into use,uttermost reduction of installing time and commissioning time.

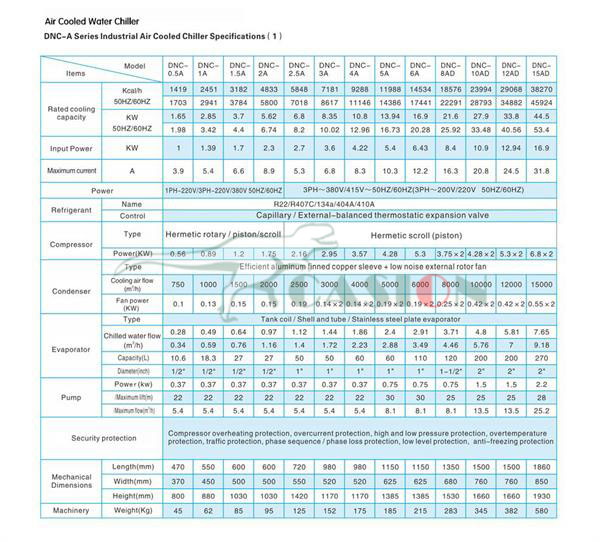

Notes:

1.Rated cooling capacity is based on: chilled water inlet and outlet water temperature 12℃ /7℃,the cooling air inlet and outlet temperature 30℃ /35℃

2.Scope of work: chilled water temperature range: 5℃ to 35℃; chilled water inlet and outlet temperature difference: 3℃to 8℃.

The ambient temperature of condensation: Not higher than 35℃ (non-standard chiller ambient temperature of condensation can reach maximum 55℃,need to order production).

These models above can be customized according to customers' requirements.

Specifications and dimensions above are subject to change without notice.

Model Description: A represents air-cooled; D represents two compressors; T represents three compressors; F represents four compressors.

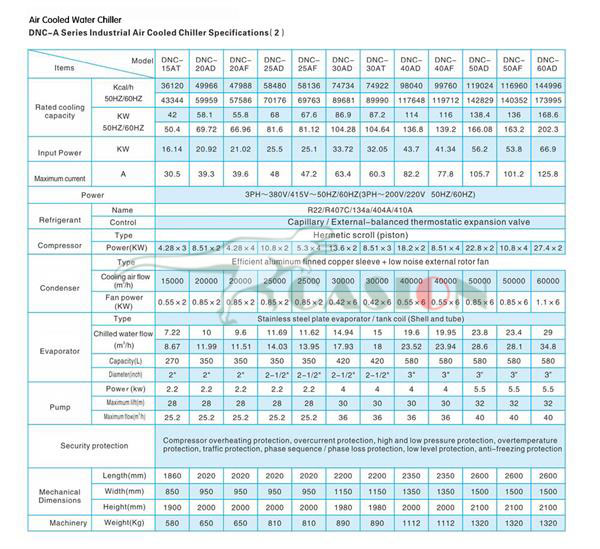

Notes:

1.Rated cooling capacity is based on :chilled water inlet and outlet water temperature 12℃/17℃.the cooling air inlet and outlet

temperature 30℃/35℃

2 Scope of work: chilled water temperature range: 5℃ to 35℃; chilled water inlet and outlet temperature difference: 3℃ to 8℃.

The ambient temperature of condensation: Not higher than 35℃ (non-standard chiller ambient temperature of condensation can reach

maximum 55℃ ,need to order production ).

These models above can be customized according to customers' requirements.

Specifications anddimensions above are subject to change without notice.

Model Description: A rapresents air-cooled; D represents two compressors; T represents three compressors; F represents four compressors.

Related Keywords