PP PE film washing plastic recycling line

- Payment Type:

- T/T, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean, Land, Air

- Port:

- SHANGHAI, NINGBO, ZHANGJIAGANG

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200-300kg/h, 500-600kg/h, 800- |

| Payment Type: | T/T,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| HS Code: | 84778000 |

| Transportation: | Ocean,Land,Air |

| Port: | SHANGHAI,NINGBO,ZHANGJIAGANG |

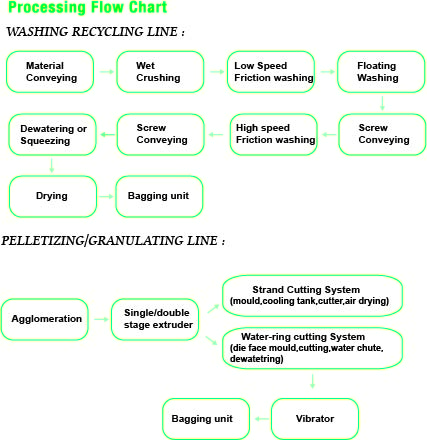

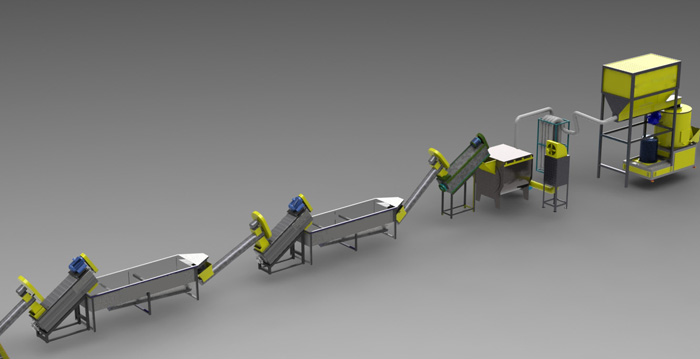

PP PE film washing plastic recycling machine:

A typical Washing plant is consist of the following components:

1. Belt conveyor: For waste material infeeding.

2. Shredder: For material size reduction. Single shaft shredder &Plastic Double Shaft Shredder could be all choosed as per different plant's needs.

3. Crusher/Granulator: Wet crushing system.It used for material size reduction and pre-washing.

4.High speed Friction washer( Scrub washing machine): High speed friction Plastic Washing Recycling Line could achieve a good cleaning effects through the blades on the beating and spray. This machine is suitable for broken film and Plastic flakes washing.

5. Sink & Float separation tank : for impurities precipitating separation and wash the material more clean.

6. Horizontal dewatering machine( Dehydrator):This machine is mainly used for the cleaning of waste plastic after mechanical dewatering and drying, the spindle through high speed rotating threw the plastic and water to the screen, water

releases by screen, while the plastic is from the outlet to be out of the machine enters into the next procedure. The machine has a good Pipe Drying Machine effect and high energy efficiency. The blade is made of high wear-resistant materials, can be replaced

more conveniently.

7. drying pipes & transition silo: Hot air drying and transportation to final storage silo.

The whole washing plant is the turn key solution for wastes plastic film, bags recycling from varies source including materials with high contamination levels. The complete PET recycling washing line could turn collected dirty polyethylene and

polypropylene films,post-consumer bags to clean and dry film pieces which could be used for further Plastic Film Pelletizing Machine. The pellets products could be used for new plastic products manufacturing again.This line is controlled with a central electrical

control panel from the begining to the end.

Application ranges: PE, PP film, bottles, bags, woven bags, sacks ect.

Models&specifications:

|

Model |

BKL-300 |

BKL-500 |

BKL-1000 |

|

Capacity(kg/h) |

200-300 |

500-600 |

800-1200 |

|

Power consumption(kw) |

125 |

260 |

400 |

|

Water consumption(t/h) |

3 |

4-5 |

6 |

|

Labor |

2-3 person |

2-3 person |

3-5 person |

|

Final products humidity |

≤5% |

≤5% |

≤5% |

Features:

1. Final products has good quality.

2. The whole line capacity between 200kg/h-2000kg/h.

3.Washing machine Parts which contact material use SUS304 with high thickness to ensure long service lift time

4. World famous brand components applied on the production line- famous brand bearing, Siemens contactor, RKC temperature, ABB inverter, Siemens PLC control etc

5. The whole production line with CE , ISO9001 certification

After discussion with our customers, We can provide effective, customized proposals and turn-key solutions by listening to and understanding our customers` needs.

Customers are warmly welcomed and encouraged to visit our factory to check some machines in operation.

Any more detailes you need, please feel free to contact with us.

Related Keywords