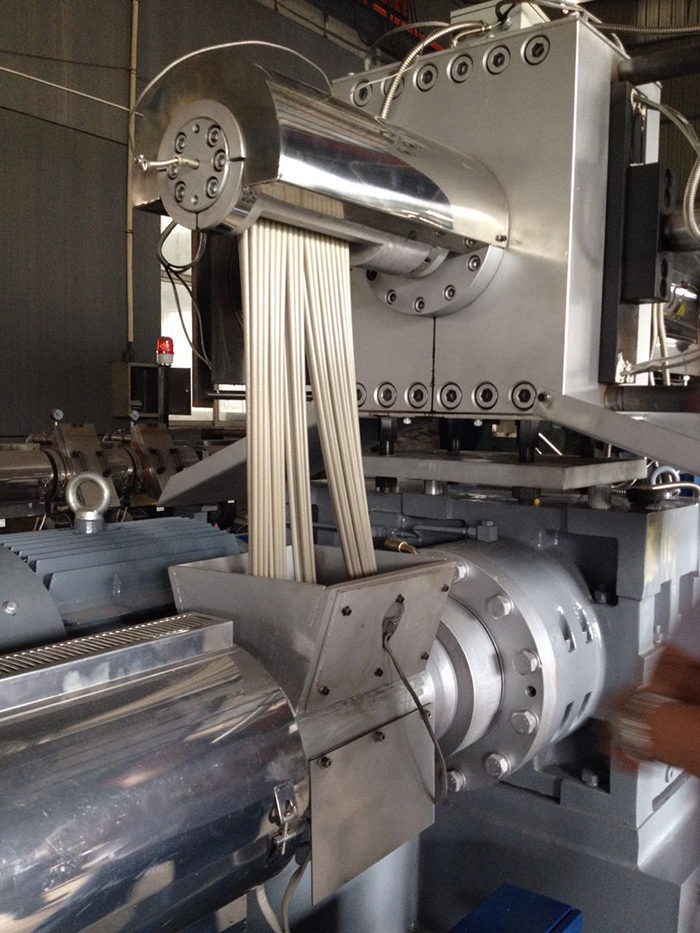

Plastic recycling pelletizing machine

- Payment Type:

- T/T, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 50 Days

- Transportation:

- Ocean, Land, Air

- Port:

- SHANGHAI, NINGBO, ZHANGJIAGANG

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Transportation: | Ocean,Land,Air |

| Port: | SHANGHAI,NINGBO,ZHANGJIAGANG |

PP regrind flakes Conical Two Screw Extruder Granulating,also called double stage ( mother & baby type ) extrusion Plastic Film Pelletizing Machine.

The Pe Film Single Stage Pelletizing Line adopts two stage extruders, which is special design for recycled washed material such as PP, PE, ABS and PS material etc.

Single stage Single Screw Extruder is also suitable for some material tend to clean&dry enough.

This line can adopt different Pe Film Single Stage Pelletizing Line method according to different molds, such as strand type of pelletizer, water ring pelletizer, and underwater pelletizer.

This type Plastic Extrusion Pelletizing Machine has single screw design,effective degassing and filer(hydraulic screen changer) system,with stable output and long service life.

Machines are highly-automatic, only need 2 workers for operating the whole pelletizing production line.

Applications:

Applicable plastic materials: PE, HDPE, LDPE,PP, PA,PC,ABS,PS etc

Material shapes: bottle flakes, crushed film/bags and regrind material

Note: depending on different material properties, various downstream equipments are needed.

Models&specificaions:

|

Model |

Extruder model |

Screw diameter |

L/D |

Capacity |

|

BKL100/90 |

SJ100 |

100 |

22 |

100-200kg/h |

|

SJ90 |

90 |

12 |

||

|

BKL120/100 |

SJ120 |

120 |

22 |

150-300kg/h |

|

SJ100 |

100 |

10 |

||

|

BKL150/120 |

SJ150 |

150 |

22 |

300-450kg/h |

|

SJ120 |

120 |

10 |

||

|

BKL180/150 |

SJ180 |

180 |

22 |

500-800kg/h |

|

SJ150 |

159 |

10 |

Related Keywords