Monodisperse Spherical Silica Gel UniSil 1.7-C18

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean,Air |

UniSil® is a series of monodisperse spherical porous silica gels used for chromatography,

produced by Suzhou Nanomicrotech Co. Ltd. from its unique patented technology that

is developed in-house. UniSil® series of products meets the requirements

of high performance liquid chromatography (HPLC) analysis in the laboratory and

preparative separations in industry scale.

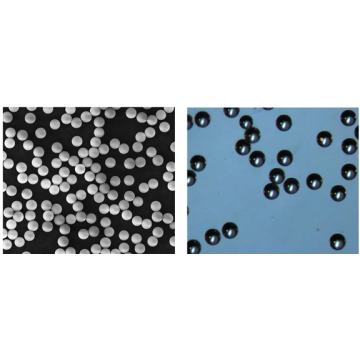

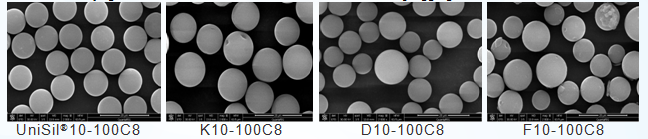

Figure 1. SEM micrographs of UniSil® monodisperse chromatography silica gel

Features and Benefits of UniSil®

|

Features |

Benefits |

|

High uniformity of particle size and perfect spherical shape |

Easy column packing, low back pressure, high efficiency and resolution |

|

Optimal pore structure |

High loading capacity and high selectivity |

|

Unique surface bonding technology |

Good acid and alkaline resistance, broad application pH range |

|

High mechanical strength |

Robust column packing and repacking, long lifetime |

|

Large scale production |

Consistent product quality, short delivery circle |

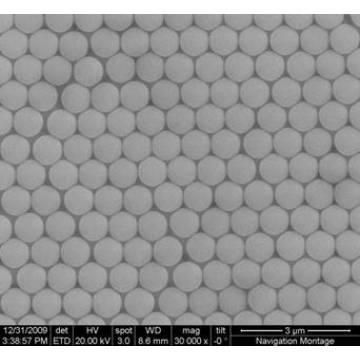

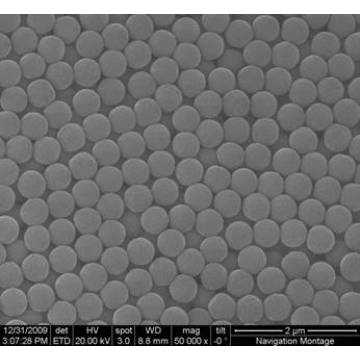

High uniformity of particle size and perfect spherical shape

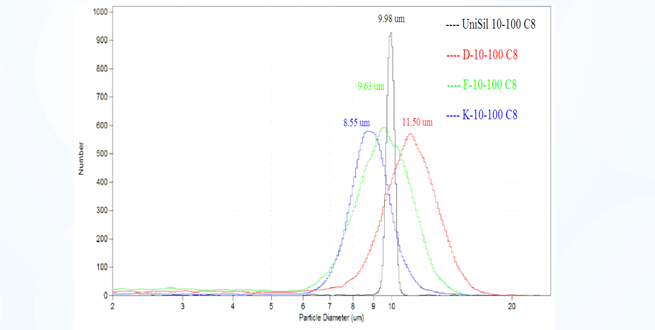

UniSil® silica gel media are made to in precise particle sizes with exceedingly high uniformity and perfect spherical shape (Figures 2 and 3). When compared to other commercial chromatography silica gels ( with broader particle size distribution), UniSil® has great advantages of easy column packing, low back pressure, high column efficiency, good resolution, stable column bed and reduced frit plugging.

Figure 2. Comparison of UniSil® and well-known international brand chromatography silica gel

Figure 3. Particle size distribution of UniSil® and well-known international brand chromatography silica gel

Figure 4. Flow characteristics in chromatography media of different particle size distributions

Optimal pore structure

The pore structure of silica gel has a great influence on its mechanical strength, separation ability, and loading capacity. Nanomicrotech not only controls precisely the particle size and size distribution of the silica gel, but also optimizes pore structure forming, desired surface area and pore volume. As the result, UniSil® silica gel has high loading capacity, strong mechanical strength, and superior separation capability.

Unique surface bonding technology

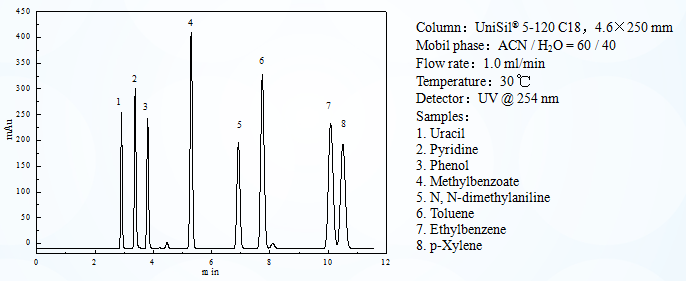

The selectivity and lifetime of a silica gel are often determined by the bonding phase on its surface and end-capping. In addition to the world leading technology of making silica gel, Nanomicrotech has developed unique techniques of surface bonding and end-capping, which enable UniSil® to be used with a broad pH range of application, good separation selectivity, and peak symmetry. To meet customer needs, Nanomicrotech also provides a variety of polar and non-polar bonded phase silica gel(C18,C8,C4,Phenyl,NH2,CN,Diol).

Figure 5 showed the separation of various chemical substances by UniSil® 5-120 C18 reverse phase silica gel media, including pyridine (alkaline compound). The high column efficiency and sharp and symmetric peaks indicated the minimal residual silanol groups on the surface (due to good end-capping).

Figure 5. Chromatographic separation of various compounds by UniSil® 5-120 C18

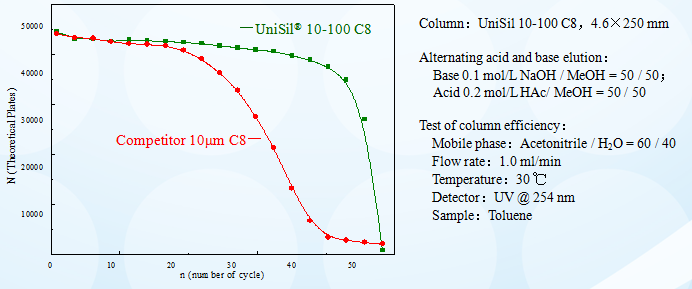

Exceptional chemical stability and resistance against acid and base

Nanomicrotech`s unique bonding and end-capping techniques gave UniSil® exceptional resistance to acidic and alkaline environment. Figure 6 showed a comparison of UniSil® 10-100 C8 with a leading commercial brand, in terms of column efficiency (after alternating elution of columns with acidic and alkaline solutions). The results indicated that the column packed with UniSil® maintains the column efficiency much better than the other with commercial silica gels, suggesting a stronger resistance against acid and base.

Figure 6. Comparison of column efficiency, between UniSil® 10-100 C8(green)and leading commercial brand(red), after treatment with acid and base

Large scale production capability and lot-to-lot consistency

State-of-the-art manufacturing facility at Nanomicrotech allows a large scale production of UniSil® to meet the demands of industrial separation. Good quality control system also assures the high quality and good lot-to-lot consistency (as shown in Figure 7).

Figure 7. Lot-to-lot consistency of UniSil® silica gel

Applications

Nanomicrotech has an in-house application development group with vast experiences. This group provides customers with a lot of technical services, from process development to technical transfer for production (industrial scale). UniSil® silica gel media have been successfully applied to the isolation and purification, including plant extracts(huperzine A, ginkgolide, panax notoginseng saponins), antibiotics(vancomycin, daptomycin, caspofungin, tiacumicin, Pneumocandin B0, cyclosprin, erythromycin), polypeptides (tacrolimus, thymalfasin, bivalirudin)and others(cod liver oil, bortezomib, flurbiprofen axetil), etc.

List of Products

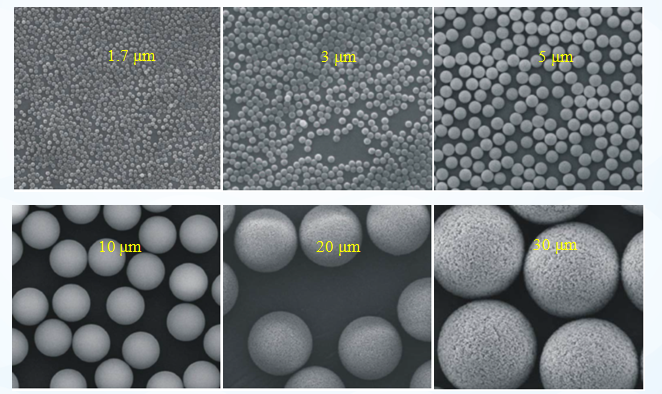

Nanomicrotech supplies spherical silica gel media in the size range of 1.7 to 50 μm, with different pore sizes, meeting the needs of high performance chromatographic (HPLC) analysis in the lab and also preparative separation in industrial scale.

|

Products |

Particle Size |

Pore Size |

Base Material |

Functional Groups |

|

μm |

Å |

|||

|

UniSil® |

1.7,3,5,10,20,30 |

60,100,120,200,300,500 |

Silica |

None,C18,C8,C4,NH2,Phenyl,CN,Diol |

|

NMSil |

40~75,75~180 |

100 |

Silica |

None,C18,C8,C4,NH2,Phenyl,CN,Diol |

Related Keywords