Industrial Engineering Sewing Data

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Supply Ability: | 200 SETS/MONTH |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE/ISO 9001 |

| Transportation: | Ocean,Air |

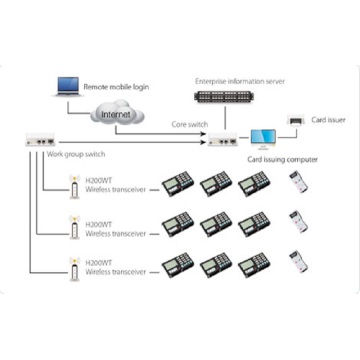

Clothes Making Process Analysis System

Clothes making process analysis system is a specialized action time predeterming system designed for sewing industry, an easy and understandable method analysis technique and can be used for evaluating such operations as sewing, ironing, inspecting and packing.

Function Module

Basic working procedure

The basic data for the system analysis is set up, such as the rule of the database, the coefficient of the fabric, the machine, the coefficient of the vehicle, the binding parameters, etc.

Process analysis

The operations through the manufacturing process analysis of action refinement analysis, combined with the use of equipment and auxiliary tools, to effectively avoid the operator is not standardized, no value of the action, and ultimately the formation of industry technology standard working hours, wages, for employees to provide work according to the standard.

Process comparison

Garment management data can be analyzed in order to make a comparison, and make a comparison, to ensure that the optimal working method to promote the full implementation.

Style analysis

According to the process of setting up the static database free components of a variety of different styles of process information, can be free to export the details of the process, and to see the details of the action and the details of the design process.

Employee skills

According to the staff of different processes to the extent of the list of staff skills, management personnel to understand the skills, and to facilitate the team leader in the new process of human space layout.

Process allocation

According to the style, the team personnel and the personnel to the each working procedure, the list of the most reasonable arrangement of personnel.

Production balance

Master different skills, for different styles, to make reasonable arrangements for the staff, so that the work of each workstation to achieve more reasonable, more smooth convergence of each process, more smooth flow line. Reduce staff waiting time, improve the efficiency of staff and work enthusiasm.

Human machine layout

Production site management program provides a variety of water mode selection, automatic layout of the human vehicle parking plan proposed to establish a scientific and reasonable production of the pre equilibrium model.

Efficiency query statistics report

Establish effective production efficiency index, stable quality and accurate calculation of the production cycle, a planned order allocation, the system automatically calculates the time output and the proportion of the standard output. In the way of data report, a clear understanding of the production and production efficiency, stability and gradually improve the production value, to achieve efficient work.

Report form

Based on the results of the analysis of the style, the summary of the report, such as the process analysis table, machine requirements, process allocation table, etc., all system data support export.

Company Information

ChangShu Bealead Automatic Machine Co.,LTD, located in changshu, jiangsu ,china. Close to ShangHai Port, driving for 1.5hours, transportation convenient.

Our company is R&D manufacturer of intelligent device for clothing production. We are in leading

position in Down feather filling area, covered most of Chinese market, Bosideng, Luo Lai, UNI QLO, are our customers.

We also have agents overseas, and more than 20 technecians for after sales service. They could answer you and service you at the first time you need.

Our Factory

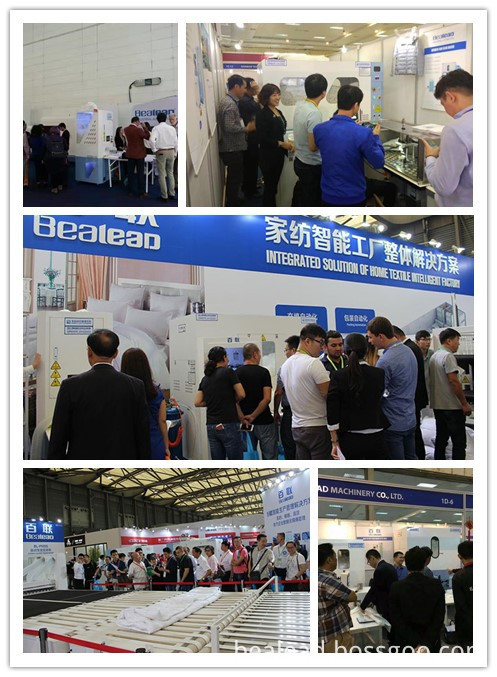

Exhibitions

Related Keywords