CNC Sinker EDM Machine

- Payment Type:

- T/T

- Incoterm:

- FOB, CFR, CIF

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean,Land |

Die EDM Sinker Machine DM3150K-II

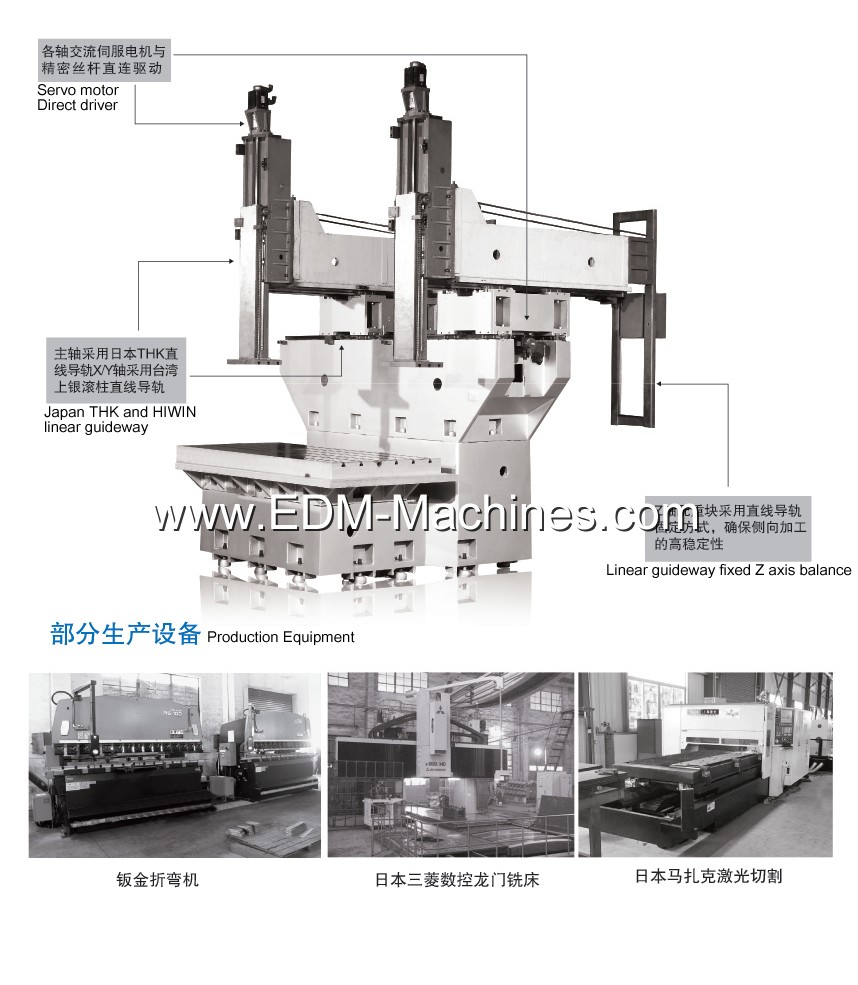

Experience on big size CNC EDM machine

Worktable fixed type CNC Sinker EDM machine

Mirror grade filter system

Sodick EDM technology support controller system

Famouse parts like Panasonic servo motor, HIWIN linear guideway, HIWIN ball screw, schneider electrical to make sure quality

The system with a lot advanced technology for example automatic process function, automatic positioning function, automatic clean arc and short circuit. It includes tool raise high-speed adaptive system,discharge pulse detection system and energy pulse control system to short machining time and get best precision

• High Performance

• Electrode Consumption 0.01%

• CNC Mirror Sinker EDM

• Economic

• Precision ± 0.005mm

• Efficiency≥500mm3 / min

Item

Unit

DM1680K-Ⅱ

DM1880K-Ⅱ

DM2180K-Ⅱ

DM3510K-Ⅱ

Machine Size

mm

6800*3800*3750

6900*4050*4050

7000*4050*4050

8500*5500*4200

Machine Weight

kg

12500

15000

18000

26000

X,Y,Y Travel

mm

(1100*2)*800*500

(1200*2)*800*500

(1400*2)*800*600

(2600*2)*900*600

Working area

Worktable Size

mm

1700*1000

2000*1000

2500*1200

3500*1200

Loading

kg

6000

7000

7000

15000

Machining area Size

mm

2628*800*500

3000*1540*700

3200*1650*740

4500*1800*700

Distance from electrode chuck to worktable

mm

600*1150

600*1200

600*1200

650*1250

Power

Machine Power

kw

9+9

9+9

9+9

9+9

Max Current

A

50+50

50+50

50+50

50+50

Max electrode weight

kg

220

250

300

350

Max speed

mm³min

≥500

≥500

≥500

≥500

Min electrode wear rate

0.05%

0.05%

0.05%

0.05%

Roughness

um

≤0.1um

≤0.1um

≤0.1um

≤0.1um

System

Input

Touch screen, USB

Display

15-inch LCD screen (TFT-LCD), CRT

Each Axis Compensation

Steps

error compensation, backlash compensation for each axis

separately

Technology Standards

steel / steel, fine steel/steel, graphite / steel, copper thin copper tungsten / steel, copper and tungsten / carbide copper / aluminum,Graphite / heat-resistant alloys, graphite / titanium, creating a processing copper / steel

Processing Discharge Conditions

Registration function 1000 conditions (C000-C999)

CNC axis

Three

axis linkage (standard),axis four linkage (optional)

Input Range

+9999.999~-9999.999

Main Parts List

| No. | Parts | Brands | Orginal | |||||

| 1 | linear guideway | Hiwin | Taiwan | |||||

| 2 | Ball screw | Hiwin | ||||||

| 3 | X,Y,Z motor | Panasonic AC servo motor and driver.Power 400W/2500 | Japan | |||||

| 4 | Main board | AAEON,Industrial garde | Taiwan | |||||

| 5 | Capacitance | Kingbox | Japan | |||||

| 6 | Circuit breaker | Schneider | France | |||||

| 7 | LCD | BOE,Industrial garde | China | |||||

| 8 | Power Sup | MeadWell,Industial garde | Taiwan | |||||

| 9 | Contactor | T-Verter,Industrial garde | Taiwan | |||||

| 10 | Air switch and limit switch | Omron | Japan | |||||

| 11 | Communications wire and cable | Hitachi | Japan | |||||

| 12 | Connector | Nanshi | China | |||||

| 13 | IC chip | NXP / ATMEL / ALTERA | ||||||

| 14 | Diodes, transistors | Vishay | American | |||||

| 15 | Three rectifier bridge | SANTEX | Japan | |||||

| Emergency stop | IDEC | Japan | ||||||

| 16 | Intermediate relay | Japan | ||||||

| 17 | Optocoupler | Toshiba | Japan | |||||

| 18 | Volt-Ammeter | YOKOWAGA | Japan | |||||

Related Keywords